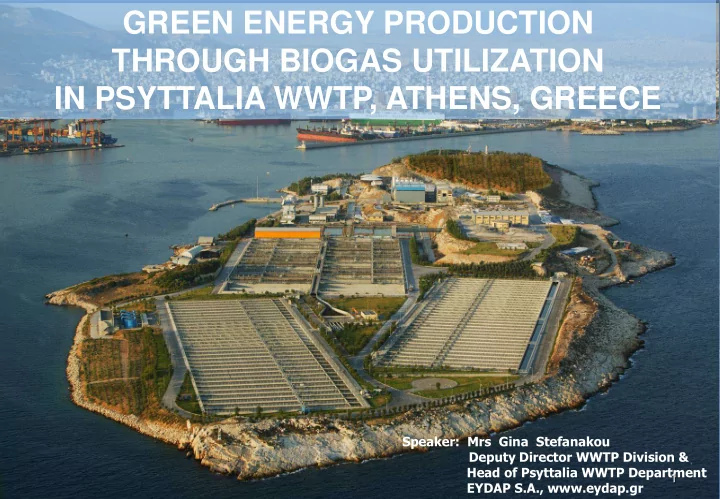

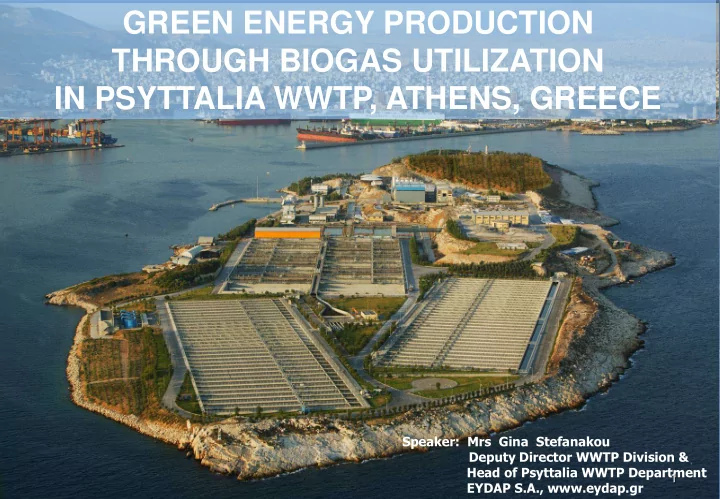

GREEN ENERGY PRODUCTION THROUGH BIOGAS UTILIZATION IN PSYTTALIA WWTP, ATHENS, GREECE Speaker: Mrs Gina Stefanakou Deputy Director WWTP Division & Head of Psyttalia WWTP Department 1 EYDAP S.A., www.eydap.gr

EYDAP S.A. Athens Water-Supply and Sewerage Company S.A. • Formed in 1980 through merging of the Greek Water Company (utility) and the Athens Sewerage Organization (state-owned) • Athens Stock Exchange entry in 1999 • Current Shares: 61 % Greek State 10 % Agricultural Bank of Greece (state-owned) 29 % Private shareholders • Personnel: 2900 2

EYDAP S.A. Athens Water Supply and Sewerage Company Serves the population of Athens metropolitan area with Water services 4 Water treatment plants (Galatsi, Menidi, Kiourka, Aspropyrgos) 8.400 km of water distribution network Wastewater collection 6.000 km of sewer network Wastewater treatment 2 plants in operation (Psyttalia, Metamorphosis) 1 plant in test operation (Thriassio WWTP - West Attica) 5 plants in design phase (Peania-Kropia WWTP, N. Makri-Marathon WWTP, North Mesogaea WWTP, Lavreotiki WWTP & Fokea WWTP - East Attica) 3

Salamina installations Akrokeramos installations Psyttalia island Port of Piraeus 4

Psyttalia Wastewater Treatment Plant Construction Phases Psyttalia WWTP installations were constructed by the Greek Ministry for the Environment, Physical Planning and Public Works, with European Union co-funding, in three phases: 1994 Phase A’ works completion, including wastewater pretreatment and primary treatment installations, primary sludge treatment installations, inverted siphon system for pretreated wastewater transport to Psyttalia and submerged outfall system for treated wastewater dispersion to the Saronic Gulf. 2004 Phase B’ works completion, including wastewater biological treatment installations and surplus activated sludge treatment installations. 2007 Phase C’ completion – construction of sludge thermal drying unit. 5

Psyttalia Wastewater Treatment Plant Construction Phases Additionally, the following works have been constructed at Psyttalia WWTP by EYDAP S.A. with European Union co-funding: Wastewater pretreatment unit on Salamina Island and submerged pipes for wastewater transport from Salamina to Psyttalia (2002) Two cogeneration plants for heat and power (CHP) utilizing biogas (2001 & 2009) and One CHP plant utilizing natural gas (2009) 6

Psyttalia Wastewater Treatment Plant Population equivalent (design, peak): 5 600 000 Design flow-rate (mean): 1 000 000 m 3 /d Peak flow-rate : 27m 3 /s (Phase A) 16 m 3 /s (Phase B) 7

Psyttalia Wastewater Treatment Plant Psyttalia WWTP Flow - diagram SCREENING PRIMARY WASTEWATER INFLOW PUMPING GRIT REMOVAL SEDIMENTATION ELECTRIC ENERGY COGENERATION (BIOGAS) BIOGAS THERMAL ENERGY GRAVITY THICKENING DIGESTION DEWATERING (TANKS) NATURAL GAS ELECTRIC ENERGY THERMAL ENERGY COGENERATION DRYING (NATURAL GAS) DRIED SLUDGE UTILIZATION EFFLUENT FINAL SETTLING TANKS BIOREACTORS PUMPING MECHANICAL SLUDGE THICKENING (BELTS) 8 8

Grit Removal Akrokeramos Screening Installations Debris Wastewater Pretreatment Removal Odor Control Twin inverted siphon 9 9

Psyttalia Wastewater Treatment Plant Wastewater treatment processes Akrokeramos (mainland) Inlet Pumping Station 9 Archimedes Screw Pumps capacity 3m 3 /sec each, total capacity 27 m 3 /sec Pretreatment Screening 6 pairs of screens (30 / 10 mm) Grit removal 6 aerated spiral-flow channels Odor control (sodium hydroxide and sodium hypochlorite solutions, air treatment capacity 140 000 m 3 /h) Wastewater transport to Psyttalia through twin inverted siphon system 10

Psyttalia Wastewater Treatment Plant Wastewater pretreatment (Salamina island) Population served 7 000 (start of operation), 32 000 (full service) Flow-rate Peak 700 l/s Average (full service) 7000 m 3 /day Pretreatment Screening: Screen (20 mm) Grit removal: Aerated spiral-flow channel (retention time 3 min) Wastewater transport to Psyttalia through twin pipe system Current status of operation: Limited flow, pending further service connections 11

Psyttalia Wastewater Treatment Plant Final Settling Filtration Biological Treatment Sludge Digesters Sludge Thermal Drying Primary Treatment Gas-holders C.H.P. Wastewater Inlet Channel 12

Psyttalia Wastewater Treatment Plant Wastewater treatment processes Psyttalia island Primary sedimentation 6 tanks (combined area 12 000 m 2 ) Biological treatment 12 bioreactors (combined volume 300 000 m 3 ) Organic load removal and nitrogen reduction Final settling 64 rectangular tanks (combined area 52 000 m 2 ) Filtration - Disinfection 3 sand-filters (one spare; com. capacity 1500 m 3 /h) and mechanical filters 2 UV disinfection units Production of process water, for use in facilities on Psyttalia Outfall system Two main pipes (1870 m long each, depth 65m) Receiving waters: Inner Saronikos Gulf 13

Psyttalia Wastewater Treatment Plant Effluent Disposal Requirements Based on Approved Environmental Terms according to Directive 91/271/EEC : Treated Effluent Concentration (mg/l) BOD 5 25 COD 125 Suspended Solids 35 Total Nitrogen Removal (%) >70 14

Psyttalia Wastewater Treatment Plant Typical wastewater inflow characteristics (mg/l) COD: 720, BOD 5 : 320, TSS: 350 Operation efficiency Load reduction (%) exceeding COD 93 BOD 5 93 TSS 93 Total Nitrogen 75 15

Psyttalia Wastewater Treatment Plant Sludge Treatment Processes - Biosolids Thickening Primary sludge gravity thickening Surplus activated sludge thickening Sludge mixing Digestion Dewatering Thermal drying Biosolids : Organic products of municipal wastewater treatment that can be beneficially used. 16

Psyttalia Wastewater Treatment Plant Sludge Τ hickening Primary sludge: Fine screening Six screens (5 mm gaps) Gravity thickening facilitated / aided by use of polyelectrolyte solution 3 tanks (combined area 1500 m 2 ) Odor control unit (2 lines) Waste activated sludge: Mechanical thickening aided by polyelectrolyte 14 belt thickeners (comb. capacity: 1750 m 3 /h) Sludge in-pipe mixing prior to digestion 17

Psyttalia Wastewater Treatment Plant Sludge Digestion Method: anaerobic, mesophilic, high-rate Installations: 8 digesters (combined volume 80 000 m 3 ) Type: Cylindrical, conical bottom, fixed-cover (dome-like) Mode of operation: parallel Biogas production from partly destruction of sludge organic content Mixing medium: Compressed biogas Heating medium: Water Heating source: Cooling water from CHP plant using Biogas 18

Psyttalia Wastewater Treatment Plant Anaerobic Digestion Methane-producing Extracellular Acid-producing microorganisms enzymes microorganisms CH 4 Organic Complex Soluble Acids Hydrolysis Methane Formation Acids Organic Organic CO 2 Formation Compounds Compounds Glucose Carbohydrates Acetic Acid Cells (Biomass) Amino-acids Proteins Propionic Acid Stabilized Organic Fatty Acids Lipids Lactic Acid Compounds -3 ) Phosphates (PO 4 Phosphorylated Cells (Biomass) Organics 19

Psyttalia Wastewater Treatment Plant Sludge Digestion Phase A digesters: 4 Heating and mixing: 6 heat-a-mix units in each tank Phase B digesters: 4 Heating: external heat exchangers Mixing: top-mounted hanging lances 20

Psyttalia Wastewater Treatment Plant Biogas temporary storage Biogas produced at the anaerobic digestion plant is temporarily stored in the gas-holders (two tanks with 5600 m 3 capacity each) and it is utilized as a fuel at the sludge thermal drying unit and at the gas- engines of the CHP plant. 21

Psyttalia Wastewater Treatment Plant Dewatering plant Decanter characteristics • Number: 6 Dewatering Plant (foreground) • Type: Centrifugal • Capacity: 70 m 3 /h each • Bowl diameter / length (mm): 725 / 2911 22 22 22

Psyttalia Wastewater Treatment Plant Sludge Thermal Drying Sludge Thermal Drying Unit Cogeneration plant for Heat and Power production (CHP) utilizing natural gas (gas-turbine) 23

Psyttalia Wastewater Treatment Plant Sludge Thermal Drying Rotating Drum Method Granular sludge Hot gases Dried granules and water-vapor carrying gases Thermal drying plant evaporating capacity: 40 t water / h (4 parallel units) Hot gases temperature: 400 o C 24

Psyttalia Wastewater Treatment Plant Utilization of Biogas produced at Psyttalia WWTP 25 25

Psyttalia Wastewater Treatment Plant The need for sustainable development combines environmental protection with meeting energy needs and in this framework the full utilization of available renewable energy sources including biogas, is a continuous necessity and one of the major goals for Psyttalia WWTP. 26

Psyttalia Wastewater Treatment Plant Sludge Digestion Biogas Composition of biogas produced from the sludge anaerobic digestion process • Methane CH 4 61 - 65 % • Carbon Dioxide CO 2 34 - 38 % • Nitrogen Ν 2 0.05 % • Oxygen Ο 2 0.0001 % • Hydrogen Sulfide H 2 S 1000 - 2000 ppm 27

U T I L I S Α T I O N BIOGAS PRODUCTION IN DIGESTERS BIOGAS STORAGE IN GAS HOLDERS D I G E S T E R BIOGAS SLUDGE THERMAL DRYING GAS-HOLDER GAS-HOLDER SLUDGE DIGESTER HEATING CLOSED CIRCUIT CHP BOILER PLANTS BURNERS HEAT DIGESTER HEATING HEAT EXCHANGER NATIONAL PSYTTALIA ELECTRIC GRID WWTP ENERGY MANAGER ON-SITE CONSUMPTION ENERGY SALE 28

Recommend

More recommend