Insulatio Insulation Materials: n Materials: From Fiberglass to - PowerPoint PPT Presentation

Insulatio Insulation Materials: n Materials: From Fiberglass to From Fiberglass to Foam, Foam, Lambs Wool to Blue Jeans Ferna rnando o Pa Pages Ru Ruiz iz Fernando Pages Ruiz, Brighton Construction Builder thirty years

Insulatio Insulation Materials: n Materials: From Fiberglass to From Fiberglass to Foam, Foam, Lamb’s Wool to Blue Jeans Ferna rnando o Pa Pages Ru Ruiz iz

Fernando Pages Ruiz, Brighton Construction • Builder thirty years • EcoHome Contributor • Two books: “Building and Affordable House,” and “Affordable Remodel.” 2 28 February 2008

Efficiency Vermont is a Registered Provider with The he Am Amer erican ican Inst Institute itute of of Ar Archite hitect cts Continu s Continuing ing Educ Education tion Systems Systems (AIA/C (AIA/CES ES) . Credit(s) earned on completion of this program will be reported to AIA/CES for AIA members. Certificates of Completion for both AIA members and non-AIA members are available upon request. This program is registered with AIA/CES for continuing professional education. As such, it does not include content that may be deemed or construed to be an approval or endorsement by the AIA of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product. Questions related to specific materials, methods, and services will be addressed at the conclusion of this presentation.

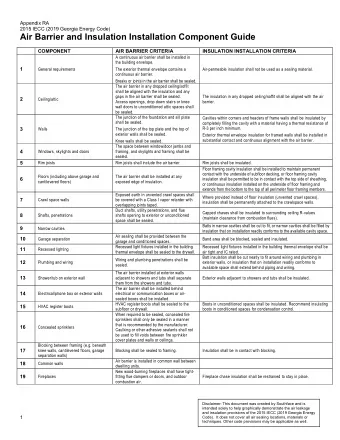

Learning Objectives At the end of this program, participants will be able to: 1. Understand insulation nomenclature such as the meaning of R value and U value. 2. Become familiar with the the features of different insulation materials and appropriate use. 3. Know the pros and cons of materials such as closed vs. open cell foams, bio-based blowing agents, and recycled products. 4. Know more about exotic insulation systems such as recycled blue jeans and lambs wool.

Course Evaluations In order to maintain high-quality learning experiences, please access the evaluation for this course by logging into CES Discovery and clicking on the Course Evaluation link on the left side of the page.

The Basics • R-Value • U-Value

R-Value = More is more. • R-value is a measure of thermal resistance used in the building industry. • The R-value depends on the type of insulation and includes its material, thickness, and density. • Heat flows naturally from a warmer to a cooler space. • Heat transfers through three means: – conduction, convection, and radiation.

Conduction • Heat moves through solid materials: Hot coffee, cold hands. • Frying pan (steal studs, anyone?) – Thermal bridging • Does heat rise?

Convection • Heat moves in any direction, including down (hence the importance of foundation insulation). • But warm AIR rises: Enter Convection. The hot air balloon effect. • Convection is a bigger issue than wind. – Hence the importance of attic sealing. – Works in reverse in summer (heavy air sinks).

Radiation • Heat moves through space. • Sunny day skiing. – Clear line of site to surface temperature. Wood stove. Un-insulated wall. – Same room, same temp., more glass feels colder. • Solar heat gain through glass increases summer bills, but lowers winter heating costs.

U-Value = Less is more. • The U-value (or U-factor ), also called overall heat transfer coefficient, describes how well a building element conducts heat. • It measures the rate of transfer through a building assembly under standardized conditions. • The standard test is set at a temperature gradient of 24 °C, at 50% humidity with no wind (a smaller U-value is better).

How does insulation work? • Some materials allow energy to pass through easily--they are good "conductors" of energy- aluminum . • Others, though, absorb heat better than they release it and these are called poor conductors, or good insulators, air . • They have High R and low U-values.

Thermal Conductivity (K) • Aluminum • 1400 • Steel • 310 • Glass • 7.8 • Concrete • 5.8 • Brick • 4.3 • Wood • 1.6 • Rubber • 1.4 • Glass wool • 0.26 • Air • 0.18 BTU-in/hr.ft.F

Insulation works in three (okay, four) ways: • A poor conductor, such as glass wool or plastic. • Forcing heat through air (or other gas) trapped in fiber mesh or cells. • Reducing convection through wall cavities. • Some materials also reflect — radiant barriers.

Climate Zones and R-Values • The US Department of Energy has recommended R-values for given areas of the USA. • Vermont is in Climate Zone …?

Zone Six Ceiling R-value 49 Wood Frame Wall R-value 20 Floor R-value 30 Fenestration U-Factor b 0.35

What does R-Value mean in the real world? • The overall R-value of a wall or ceiling will be somewhat different from the R-value of the insulation itself because some heat flows around the insulation through the studs and joists.

Whole Wall R-Values Wall Type W-W R Standard 2x4 9.7 Perfect 2x6 12.8 Poor 2x6 11 Steel frame wall 5.6 Steel w. insulated sheathing 10.5 SIPS 6-in 21.6 Stucco-straw bale 16-to-28 Concrete block 10-to-30 ICF 26-to-44

The Classic: Batt Cost: Low Air sealing: Poor Best use: Above-grade walls Other uses: Floors and roofs

Good: Fiberglass batt plus sealing and tight fit, least expensive. To perform well, they must be installed in conjunction with a very well-detailed air barrier. Unaddressed air leaks in fiberglass-insulated walls can easily lead to condensation and moisture problems. Higher density available.

Bad batting, moldy house.

Mineral Wool • Low convection – Sound deadening • Slightly high R-value • Recycled • Costly, itchy.

Cotton • Many of the same drawbacks. • More difficult to install • Recycled 85% • Acoustics >Fiber glass R-30 in a 2x6 wall. < Mineral Wool • $$$ Bonded Logic .

Wool • Slightly higher than fiberglass batts • Retains R-value when wet. • Natural insect and fire resistant. • Moth balls?

Polyester • Used in baby diapers, feminine care, hygiene, apparel, etc. • Hydrophobic – won't absorb moisture • No respiratory or skin irritation issues – no protective gear for installation • Made from recycled plastic bottles and other post-consumer material • Superior compression/recovery

Insulation & Infiltration • 31 % Floors, walls, ceiling. • 13% Penetrations

Infiltration and Wall Energy Rating

Small job, big benefits

Simple sealing techniques

Blower door test

Equal value, lower cost

Blown Cost: Low Air sealing: Low to moderate Best use: Above-grade walls, attic floors Other uses: Rafter bays

Fiberglass • Better seal than batts. • Not so itchy. • Lower R-values per inch (R-2-to-2.7) than any other, so best applied at attic. • Convection no longer a concern unless your attic -20-degrees. (Old at 0-degrees) • Bag count, beware of ―fluffing.‖ Bag count on manufacturer’s web site.

Cellulose Blown-in cellulose • choice of many green builders for insulating walls, flat ceilings, and sloped ceilings. • Made from recycled newspaper • Cellulose is inexpensive, packed in delivers R 3.8 per inch. • Better at reducing infiltration, 3.2 loose. • Disadvantage: Moisture. • Becomes soggy, holds • a lot of water. • Detection of leaks delayed.

Retrofit walls and attics

Spray Foam Cost: High Air sealing: Excellent Best use: Air sealing difficult areas Other uses: All insulation jobs

Closed-cell • Closed-cell spray polyurethane foam performs better than any other insulation. It has a high R-value per inch (R-6.2 to R-6.5), it's impervious to moisture, and it's an effective vapor retarder. It is also an excellent air barrier. Closed-cell spray polyurethane foam can be used under slabs, on below-grade or above- grade walls, in ceilings, or even as roofing. It is also the most expensive residential insulation available.

Open-cell • Open-cell spray polyurethane foam has some but not all of the virtues of closed-cell foam. Like closed-cell foam, open-cell foam creates an effective air barrier. However, open-cell foam has an R-value of about R-3.6 per inch — much less than that of closed-cell. Unlike closed-cell foam, open-cell foam absorbs and holds water. It is also vapor-permeable, which can be a virtue or a drawback, depending on the application. Open-cell spray foam costs less than closed-cell foam.

Closed cell, R-19 3.5-inches BioBased Insulation

Open cell, R-3.6-inch, 12.6 at 3.5-inches (about the same as FG) Icynene .

MD-R-200 Medium-density R-5.1 per inch. Icynene

BASF: Floo BASF: Flood are d areas, as, sucrose- based polyols. Spraytite medium-density

Hybrid systems Johns Manville

Flash and Batt • 1 to 2 inch layer of closed-cell foam and fiberglass or cellulose. • 45-55 % R-Value (condensation) • Lower cost option.

Generally, Polyurethane • When high-performance builders talk about spray- foam insulation, they’re typically talking about polyurethane. But it turns out there’s more than one kind of spray foam used in residential construction. • Phenol-formaldehyde and urea- formaldehyde insulation also are available,

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.