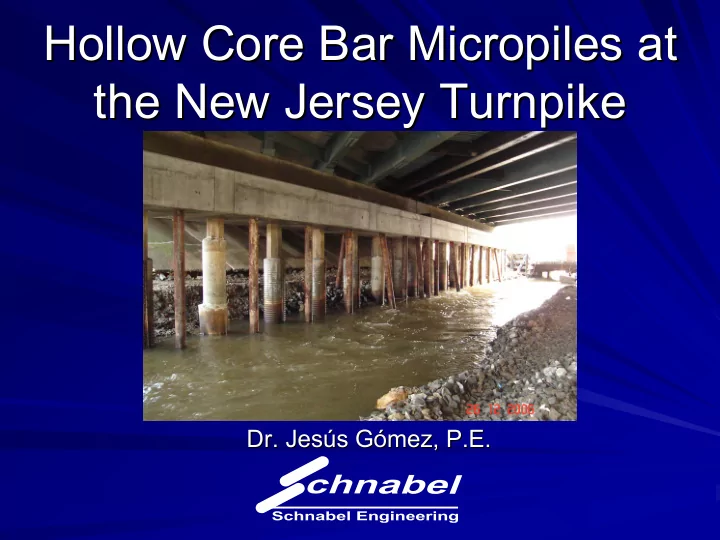

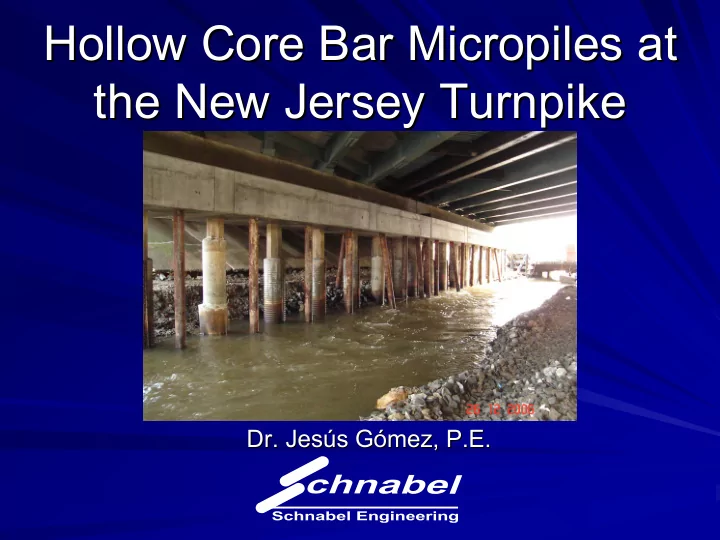

Hollow Core Bar Micropiles at Hollow Core Bar Micropiles at the New Jersey Turnpike the New Jersey Turnpike Dr. Jesús Gómez, P.E. Dr. Jesús Gómez, P.E.

Outline Outline Project Overview � Project Overview � Micropile Characteristics � Micropile Characteristics � Verification Testing � Verification Testing � Proof Testing � Proof Testing � Interpretation of Load Tests � Interpretation of Load Tests � Interpreted Bond Values � Interpreted Bond Values � Conclusions � Conclusions �

Introduction Introduction � Project Owner: New Jersey Turnpike Authority � Project Owner: New Jersey Turnpike Authority � Structural Designer: Fay, Structural Designer: Fay, Spofford Spofford & Thorndike & Thorndike � (FST) (FST) � Geotechnical Engineer: Matrix Geotechnical Engineer: Matrix � � Inspection: Inspection: Greenman Greenman- -Pedersen, Inc. (GPI) Pedersen, Inc. (GPI) � � Micropile Contractor: PKF Mark III Micropile Contractor: PKF Mark III � � Schnabel retained by PKF as Geostructural Schnabel retained by PKF as Geostructural � Consultants Consultants

Location Location Bridge 7.85 Bridge 0.42L

Location Location Bridge 7.85 Bridge 0.42L

0.42 Bridge 0.42 Bridge Bridge 7.85 Bridge 0.42L

Existing Conditions Existing Conditions

Retrofit of Existing Foundation Retrofit of Existing Foundation

Retrofit of Existing Foundation Retrofit of Existing Foundation

Bridge 0.42L (180 Micropiles) Bridge 0.42L (180 Micropiles) P3 P2 P1

Bridge 7.85 (80 Micropiles) Bridge 7.85 (80 Micropiles) P2 P1

Geotechnical Conditions Geotechnical Conditions � Bridge 0.42L Bridge 0.42L � � Very Soft Organic Silt Very Soft Organic Silt � � Sand with Silt (Medium Sand with Silt (Medium- -dense to Dense) dense to Dense) � � Sandy Clay (Stiff) Sandy Clay (Stiff) � Bridge 7.85 Bridge 7.85 � Very Soft Organic Silt Very Soft Organic Silt � � Silty Clay (Stiff) Silty Clay (Stiff) �

Micropile Characteristics Micropile Characteristics � Design Load 80 kip Design Load 80 kip � � Self Drilling, Self Grouting Bar. IBO Titan Bar 52/26 Self Drilling, Self Grouting Bar. IBO Titan Bar 52/26 � Fy = 80 ksi = 80 ksi Fy � 9 5/8 in O.D. casing, 0.5 in thickness, 9 5/8 in O.D. casing, 0.5 in thickness, Fy Fy = 50 ksi = 50 ksi � � Top Connection 12” x 12” x 1.5” steel plate Top Connection 12” x 12” x 1.5” steel plate Fy Fy = 50 = 50 � ksi ksi � Grout Compressive Strength Grout Compressive Strength f’c f’c = 4 ksi = 4 ksi �

Micropile Characteristics Micropile Characteristics � Bridge 0.42L � Bridge 0.42L Minimum Cased Length 35 ft Minimum Cased Length 35 ft Minimum Bond Length 30 ft Minimum Bond Length 30 ft Nominal Grout Body Diameter 6 in Nominal Grout Body Diameter 6 in � Bridge 7.85 � Bridge 7.85 Minimum Cased Length 45 ft Minimum Cased Length 45 ft Minimum Bond Length 40 ft Minimum Bond Length 40 ft Nominal Grout Body Diameter 9 in Nominal Grout Body Diameter 9 in � Grout Mix � Grout Mix � Drilling grout, 10 gallons water per 1 bag of cement Drilling grout, 10 gallons water per 1 bag of cement � � Final grout, 5 gallons water per 1 bag of cement Final grout, 5 gallons water per 1 bag of cement �

Micropile Observation Micropile Observation � Drilling Logs Drilling Logs � Drilling advance rate Drilling advance rate Grout pressure Grout pressure Total micropile depths Total micropile depths � Specific Gravity Specific Gravity � 1.45 to 1.60 for drilling grout 1.45 to 1.60 for drilling grout Minimum 1.8 for final grout Minimum 1.8 for final grout � Concrete Compressive Strength Test (Grout Cube Concrete Compressive Strength Test (Grout Cube � Samples) Samples) � Jack Transfusions Jack Transfusions �

Verification Testing Verification Testing � Two verification tests at each bridge Two verification tests at each bridge � � 2.5 DL 2.5 DL � � One verification test failed at each bridge One verification test failed at each bridge � � From tests taken to failure: From tests taken to failure: � � Micropiles in medium dense sand (Bridge 0.42L) : Micropiles in medium dense sand (Bridge 0.42L) : � Load Transfer Ratio = 10 kip/ft (Bond Strength = 44 psi Load Transfer Ratio = 10 kip/ft (Bond Strength = 44 psi) ) � Micropiles in stiff silty clay (Bridge 7.85): Micropiles in stiff silty clay (Bridge 7.85): � Load Transfer Ratio = 4.1 kip/ft (Bond Strength = 18 psi psi) ) Load Transfer Ratio = 4.1 kip/ft (Bond Strength = 18

Proof Load Testing Proof Load Testing � 100% of micropiles satisfactorily proof load tested 100% of micropiles satisfactorily proof load tested � � Maximum proof load test limited by existing bridge Maximum proof load test limited by existing bridge � structure structure � 1.25 to 1.5 DL 1.25 to 1.5 DL � � 12 12- -hour load hold under DL hour load hold under DL � � Tested groups of 6 and 8 micropiles Tested groups of 6 and 8 micropiles � � Four to six sacrificial flat jacks per group Four to six sacrificial flat jacks per group � � Lock off at 0.5 DL Lock off at 0.5 DL �

Proof Load Testing Proof Load Testing

Proof Test Summary- - Sand Sand Proof Test Summary Load (kip) 0 10 20 30 40 50 60 70 80 90 100 110 120 0.0 Deflection (in) 0.1 0.2 0.3

Proof Test Summary- - Clay Clay Proof Test Summary Load (kip) 0 20 40 60 80 100 120 0.0 0.1 Deflection (in) 0.2 0.3 0.4 0.5

Load Test Interpretation Load Test Interpretation τ α ∆ s

Load Test Interpretation Load Test Interpretation P b ∆ Pb Axial Load δ be δ ⋅ Σ EA P a = = be b L 2 b be ∆ L P b be

Load Test Interpretation Load Test Interpretation � Applied elastic length concept to calculate ultimate bond in Applied elastic length concept to calculate ultimate bond in � failed tests failed tests � Compared to measured average bond values Compared to measured average bond values � � In medium dense sand: In medium dense sand: 12.4 kip/ft vs. 10 kip/ft measured 12.4 kip/ft vs. 10 kip/ft measured � � In stiff silty clay: In stiff silty clay: 5.9 kip/ft vs. 4.1 kip/ft (measured) 5.9 kip/ft vs. 4.1 kip/ft (measured) � � The elastic length concept yielded reasonably accurate The elastic length concept yielded reasonably accurate � values of bond values of bond � Applied this concept to 260 proof tests Applied this concept to 260 proof tests �

Bond Values in Medium Dense Sand Bond Values in Medium Dense Sand 30 25 Number of Micropiles 20 15 10 5 0 More 4 6 8 10 12 14 16 18 20 Load Transfer Ratio (kip/ft)

Bond Values in Stiff Silty Clay Bond Values in Stiff Silty Clay 14 12 Number of Micropiles 10 8 6 4 2 0 0 2 4 6 8 10 12 14 16 18 20 Load Transfer Ratio (kip/ft)

Bond Values in Stiff Silty Clay Bond Values in Stiff Silty Clay Bond Strength Mobilized Bond Suggested By Soil Type Strength in FHWA Proof Tests Type B micropile Medium Dense Sand 27 – 53 psi 10 – 28 psi Stiff Silty Clay 9 - 27 psi 10 – 28 psi

Closure Closure � Ultimate bond strength of hollow core bar micropiles Ultimate bond strength of hollow core bar micropiles � in sand significantly larger than typical design values in sand significantly larger than typical design values � In stiff silty clay, ultimate bond strength values similar In stiff silty clay, ultimate bond strength values similar � to typical design values to typical design values � Bond values from this work may be used as guidance Bond values from this work may be used as guidance � for preliminary design for preliminary design � Two more bridges and an additional 144 micropiles to Two more bridges and an additional 144 micropiles to � be proof tested be proof tested

THANK YOU THANK YOU

Verification Tests in Sand Verification Tests in Sand

Verification Tests in Clay Verification Tests in Clay

Recommend

More recommend