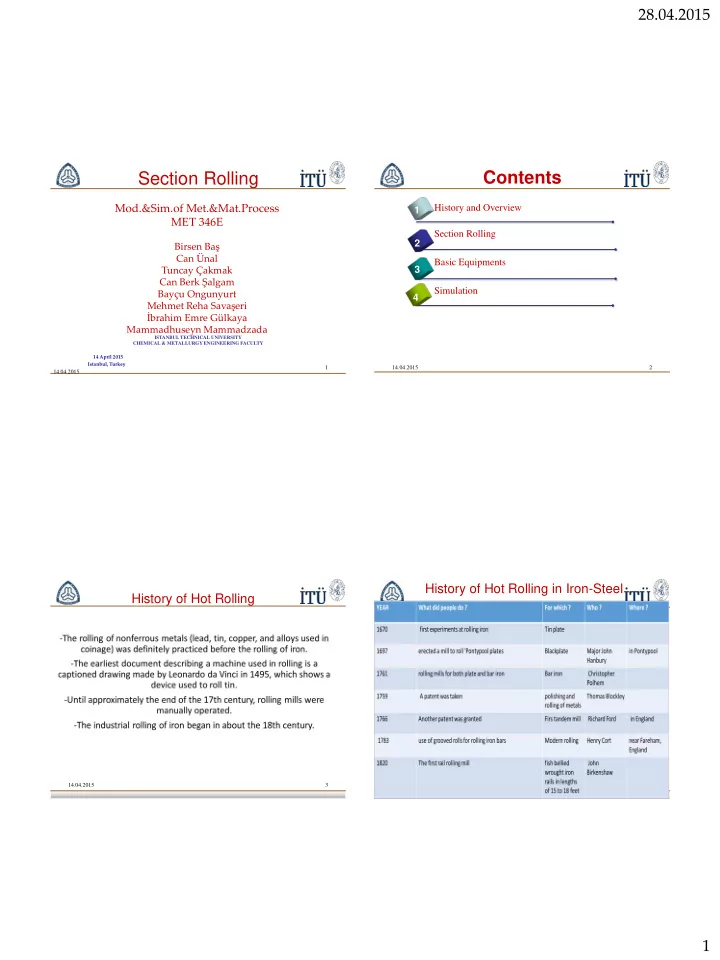

28.04.2015 Contents Section Rolling Mod.&Sim.of Met.&Mat.Process History and Overview 1 MET 346E Section Rolling 2 Birsen Baş Can Ünal Basic Equipments 3 Tuncay Çakmak Can Berk Şalgam Simulation Bayçu Ongunyurt 4 Mehmet Reha Savaşeri İbrahim Emre Gülkaya 5 5 4 Mammadhuseyn Mammadzada ISTANBUL TECHNICAL UNIVERSITY CHEMICAL & METALLURGY ENGINEERING FACULTY 14 April 2015 Istanbul, Turkey 1 14.04.2015 2 14.04.2015 History of Hot Rolling in Iron-Steel History of Hot Rolling 14.04.2015 3 14.04.2015 4 1

28.04.2015 History of Hot Rolling Section Rolling Rolling mills processes includes rolling the billets, blooms, slab and beam blanks into the prescribed size • First industrial use was made of the rolling mill with grooved rolls, and correcting any roughing, edging invented by H. Cort of Great Britain in 1783. In time, rolling mills were subdivided into cogging, sheet, and section mills. and finishing. Blooms are took a • In the 1830’s and 1840’s, the rapid development of railroads in control and rolled it into an I-beam. various countries led to the use of rolling in the manufacture of rails. • In 1856 and 1857 the first mill for rolling large beams was set up in the Saar, Germany 5 14.04.2015 6 14.04.2015 I-Beam Properties of Plate • Yield strengths exceed 300 Mpa Strength • Ultimate tensile strength is 10% I-beams are usually more higher than yeld strength made of structural steel. I-shaped • It is respect of the steel’s resistance to section is a very Toughness crack propagation. • It is ability of the energy absorption efficient form for carrying both bending and • Steel’s retention of its original Weldability *http://www.axionintl.com/images/productsilos/ibeamSolidsilo500pxs strength and toughness in the shear loads . p.jpg vicinity of welded joints. 14.04.2015 7 14.04.2015 8 2

28.04.2015 Process Reheating Slabs are heated at 1150-1270 ° C. Reheated reduces the deformation of strength of steel. The furnace incorporates machinery to transport a stream of slabs through it, and is usually fired by gas burners. *http://www.fps.com.fj/wp-content/uploads/2011/09/PAC_STEEL_rolling_mill.jpg 14.04.2015 9 14.04.2015 10 Descaling Roughing Mill Roughing stands are used to reduce the thickness of Removing of the oxide layer to build up on the steel and to form the metal to roughly the final outer surfaces of the slab. thickness. High pressure water sprays (200 bar) are used A consistent metal temperature at this point in process to remove it. is critical for a consistent surface finish and for consistent thickness. Eliminate cracking and bending Improved shape control Provides a measure of surface quality *http://steelx.org/content/media/images/hr-plate-descaler.jpg 14.04.2015 11 14.04.2015 12 3

28.04.2015 Finishing Mill Finishing Process Mill finish refers to • Cutting discrete plates the surface Shearing • Removes edge texture (or finish) of metal after it exits a rolling • Stress relieving process mill, extrusion die, Levelling or drawing process • Controlled elongation es, including sheet, bar • Ultrasound testing applied , plate, Inspection or structural • Grinding may be applied shapes *http://www.gr-inc.com/images/GGT/complete-tube-and-pipe- finishing-lines.jpg 14.04.2015 13 14.04.2015 14 Performance Tests Section Rolling Mill The resistance The resistance The resistance of the plate to of the steel of the steel a certain load plate to break plate to crack without under a heavy propagation breaking or impact must be must be deforming assessed . tested. must be checked. 14.04.2015 15 14.04.2015 16 4

28.04.2015 Section Rolling Section Rolling 14.04.2015 17 14.04.2015 18 Section Rolling Mills Section Rolling • RUGHE GHER R MILL LL • EDGER GER MILL LL • FINIS ISHER ER MILL LL 14.04.2015 19 14.04.2015 20 5

28.04.2015 Section Rolling Steps of the Section Rolling 1. Bloom Heating 2. Descaling 3. Rough Rolling 14.04.2015 21 Steps of the Section Rolling Steps of the Section Rolling 4.Finish Roling (1.stand 7. Straightening and 2.stand) 8. Head Hardening 5.Cutting to Length 9. Straightening 10.Quality and 6. Cooling Dimensional Accuracy Inspection 6

28.04.2015 Steps of the Section Rolling 11. Straightening 12.Drilling and Trimming 13. Hardening the Rail Ends 14. Final Inspection and Storing 14.04.2015 26 CSA 14.04.2015 27 14.04.2015 28 7

28.04.2015 Simulation Simulation 14.04.2015 29 14.04.2015 30 Simulation Simulation 14.04.2015 31 14.04.2015 32 8

28.04.2015 Simulation Simulation 14.04.2015 33 14.04.2015 34 Simulation Simulation 14.04.2015 35 14.04.2015 36 9

28.04.2015 Simulation Simulation 14.04.2015 37 14.04.2015 38 Simulation Simulation 14.04.2015 39 14.04.2015 40 10

28.04.2015 Simulation Simulation 14.04.2015 41 14.04.2015 42 Simulation Simulation 14.04.2015 43 14.04.2015 44 11

28.04.2015 Simulation Thank you for listening … 14.04.2015 45 14.04.2015 46 12

Recommend

More recommend