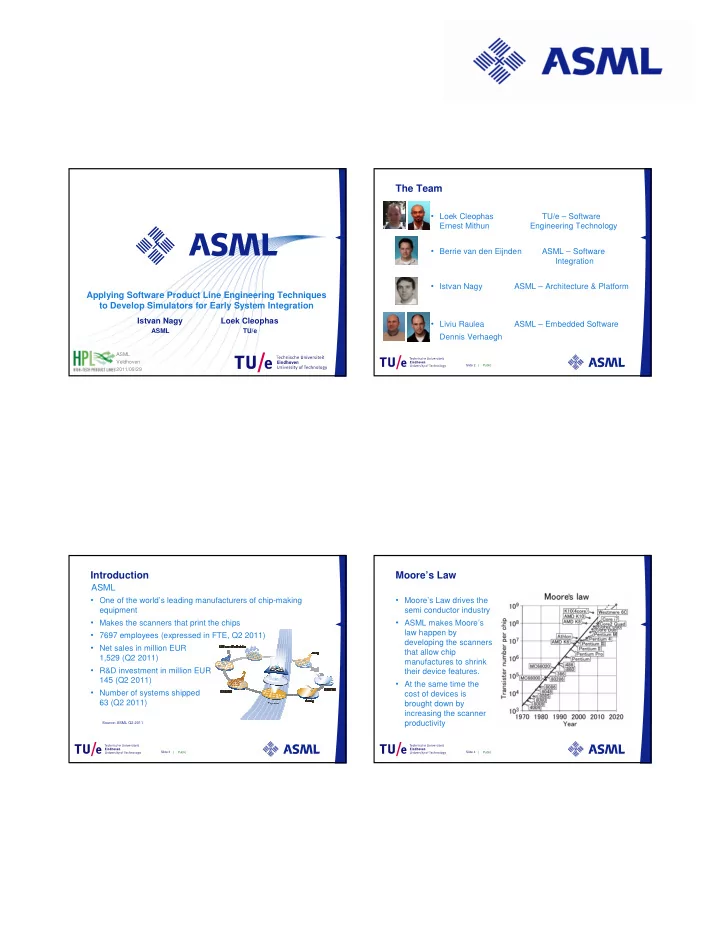

The Team • Loek Cleophas TU/e – Software Ernest Mithun Engineering Technology • Berrie van den Eijnden ASML – Software Integration • Istvan Nagy ASML – Architecture & Platform Applying Software Product Line Engineering Techniques to Develop Simulators for Early System Integration Istvan Nagy Loek Cleophas • Liviu Raulea ASML – Embedded Software ASML TU/e Dennis Verhaegh ASML Veldhoven Slide 2 | Public 2011/09/29 Introduction Moore’s Law ASML • One of the world’s leading manufacturers of chip-making • Moore’s Law drives the equipment semi conductor industry • Makes the scanners that print the chips • ASML makes Moore’s law happen by • 7697 employees (expressed in FTE, Q2 2011) developing the scanners • Net sales in million EUR that allow chip 1,529 (Q2 2011) manufactures to shrink • R&D investment in million EUR their device features. 145 (Q2 2011) • At the same time the • Number of systems shipped cost of devices is 63 (Q2 2011) brought down by increasing the scanner productivity Source: ASML Q2 2011 Slide 3 | Public Slide 4 | Public

Software Introduction Early Testing & Integration • Software tested on range from real machine to SW simulators • ASML’s scanners - lithographic systems - are complex • Objectives: machines in which software plays an important role • Shorten lifecycle of functional testing and qualification • 35 million lines of code • Optimize costs (development effort) in relation to qualification effort • Mostly C, some Java, Python ↑ , and C++ ↑ • About 7 DSLs.- increased focus on Model Driven Engineering expensive Functional completeness • > 15 years development history Proto Test Rig real robots, mirrors,… • Distributed, heterogeneous, concurrent system • > 20 nodes, > 200 processes Test Bench • Deployed onto SUN and 7 VME racks with power PCs (VxWorks DevBench inexpensive or LINUX) simulation based Availability Slide 5 | Public Slide 6 | Public Software in a Loop Simulation Finding the level of testability / simulation interface test cases test cases ����������� ��������� ������ Software real function calls to replies on sensor influence actuators, values and positions, query sensors with realistic data Software Software �������� actuators, sensors Simulators TWINSCAN Slide 7 | Public Slide 8 | Public

Finding the level of testability / simulation interface Machine Types & Platforms – Balancing Between Evolution and Revolution ����������� • ASML develops 1-3 new machine types per year ��������� • Platform: hardware foundation for range of ������ machine types. Software ������� • Platform determines maximum capabilities of member ���� ������������������ machine types ����������� �������� • Development of new platform implies major changes of ����������� �������� subsystems: “Revolution” • Example: EUV technology - ��������������������� projection in vacuum with mirrors ����������� i.s.o. lenses • Machines types built on same platform ������ ������!� have moderate changes in subsystems: “Evolution” � �������������� Slide 9 | Public Slide 10 | Public TWINSCAN Platforms and Machine Types How to Build a Wafer Flow Simulator? TWINSCAN product family ? TWINSCAN platforms XT platform NXT platform NXE platform Main downto 38 nm below 38 nm below 27 nm …try to re-create a virtual replica of the real world… upto 150 wafers/hr above 175 wafers/hr above 60 wafers/hr specifications Machine types XT:1950Hi NXT:1950i NXE:3100 Transportable Operator Interactions … XT:1900Gi Actuators Sensors Holders XT:1700Fi ... ... Material XT:1450G How to create ... wafer-flow simulators common and unique HW (& SW) modules efficiently for common and unique simulation (“virtual”) modules this product to maintain material (wafer) flow to maintain material (wafer) flow family? Slide 11 | Public Slide 12 | Public

How to Build a Wafer Flow Simulator? – Error Scenarios Need to Raise Abstraction Level 1������������������!����������� ���������������!���������!!��� �������8����������� Simplified ? modeling and programming in problem space ����!���� ��������� …however, the real world usually does not “behave” perfectly… !�������! Error-injection Scenarios in Simulation Position Sensors �������� "�� ���!� �#��� ���!� $% Transfer without Transfer with Complex Template ���� &�����'��!(�����))!�����*����+�����������&������ ����� ,!))&���-����� .�����-�����#�� ����� &*���� /�����#�(�!0$(1 /$(1�� wafer displacement wafer displacement modeling and programming in C++ � programming in ���� ����������2 Wafer ,!))&���3���� ����2� Vector Geometry Presence solution ,!))���&���3����������-���������#������4%���5��3����#� �����2 Sensor � (technology) ,!))������+���������-�������-������������#� Statecharts ���� 4%���-��-�������#������������2 space �� ���������������6�$(14% ������0����������2�7 � � Error-handling Slide 13 | Public Slide 14 | Public Model-Driven Engineering Approach Features, Variants and Binding Times (Examples) Domain-specific language Purpose Feature Variant Instance Binding Time to configure wafer flow test cases simulators of different 3DOF Robot Load Robot (LR) Device for Moveable products = contract Automated Actuation Peripheral Pin PA Pin Test Wafer Flow + Editor in Eclipse + nominal + config. with consistent Device for Fixed Discharge Unit Design Checks = Pedestal non-nominal static variation Development feedback Holding Peripheral (DU) behavior points Time Device for Light beam LS1 @ Load- Sensor Software Measurement Sensor Lock 1 Position of Coordinate Polar (…, …, …) Devices Hardware generate Simulation Wafer Lost @ & deploy model Wafer Lost Startup Time interacting Ensuring Models Load Robot Fault actuators, sensors Non-nominal Wafer (.VPDSL) Injection Wafer D(…, …) from Flow Simulator Behavior Runtime Displacement LL1 to IVR Configuration: e.g. wafers, wafer �����������4 &������� runtime size Simulation Scenarios input Fault injection : e.g. wafer found/lost, wafer displacement Slide 15 | Public Slide 16 | Public

VPDSL – A DSL for Specifying and Generating Interactions for Material Transfer in VPDSL Wafer Flow Simulators 3DOF Robot Moving Transfer Arm (Actuator) Area &������� ����!����� in generated ���������� code, no �����!�9 Wafer need to ������� (Transportable specify &:&;; Material) Fixed Geometric intersection Transfer Pedestal detected Area (Fixed) ⇒ Transfer detected ⇒ Sensors updated Slide 17 | Public Slide 18 | Public Design Workflow with VPDSL Runtime Workflow Eclipse-based Control Initialize control Xtext DSL Software software with simulator editor Specify VPDSL model Wafer X LoC !���������� Initialize injector Flow Simulator �������� Eclipse-based Read injector configuration file Robot1 Xtend/Xpand actuated to Generate simulation code DSL to C++ {r1,phi1,z1} Wait for event 12*X LoC Inject error from control software Wafer displacement injection (8*X model-dependent) during transfer if(evCheckError) [yes] Technologies in target code: •Boost state machines Displaced Check fault rules Actuated [no] [yes] •Geometry library if(satisfied) Wafer Peripheral Integrate simulation code •ASML sw. facilities [no] Light beam with control software sensor Fixed Peripheral ��������� �������� Slide 19 | Public Slide 20 | Public

Recommend

More recommend