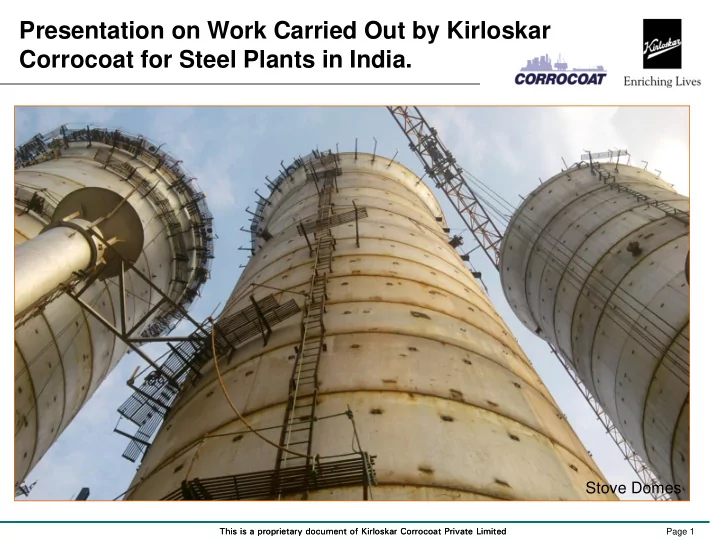

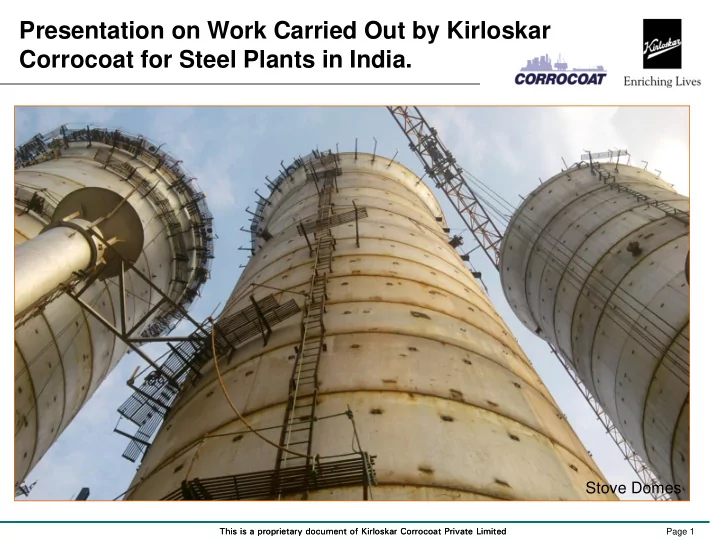

Presentation on Work Carried Out by Kirloskar Corrocoat for Steel Plants in India. Stove Domes This is a proprietary document of Kirloskar Corrocoat Private Limited This is a proprietary document of Kirloskar Corrocoat Private Limited Page 1

STOVE DOME’S This is a proprietary document of Kirloskar Corrocoat Private Limited Page 2

Technical View In cyclic operation the entire Stove dome structure undergoes huge temperature fluctuations. Many times the temperature as well as hot air / gases effect reaches up-to the outer shell of the Stove dome structure. In such situation it becomes preliminary task to protect the Metallic shell structure of the Stove dome from the corrosion due to temperature fluctuations as well as hot air / gases PART’S TO BE COATED: - STOVE SHELL – APROX. 45 MTR.S HEIGHT. - STOVE’S DOME . COATING SYSTEM: PPV + Polyglass VEF/ VEHA @ 1mm This is a proprietary document of Kirloskar Corrocoat Private Limited Page 3

This is a proprietary document of Kirloskar Corrocoat Private Limited Page 4

GAS CLEANING PLANT This is a proprietary document of Kirloskar Corrocoat Private Limited Page 5

Technical View Dust-laden blast furnace gases are cleaned in Gas Cleaning Plant. Here basically pre-cleaning, cooling and final cleaning of BF gases takes place. Certain constituents in the BF gas e.g. SO2 yields in forming weak acids like H2SO4 which are supposed to be more corrosive. The fluid stream from GCP flows through the launders. Protection of GCP as well as Launders from the weak acid attack is one of the primary task to ensure peak performance of GCP. PART’S TO BE COATED: • Conditioning tower • Demister vessel with bed. • Scrubber Arms. COATING SYSTEM: Polyglass PPV+ Polyglass VEF + FIBER MATTING Page 6

DRAWING Page 7

Page 8

This is a proprietary document of Kirloskar Corrocoat Private Limited Page 9

OTHER EQUIPMENTS…… • PULVERIZED SILOS. • DESULPHURIZATION TANKS • FLAIR STACKS. • AMMONIA OVEN TANKS • CW PUMPS. • PIPELINE (GAS & LIQUID) • STRUCTURES & many More Corrosion Prone Areas… This is a proprietary document of Kirloskar Corrocoat Private Limited Page 10

REFERENCE LIST Service Product Year of Customer Equipment Work Description Condition Applied work Coating of Demister vessel, TISCO, Polyglass Gas Cleaning conditioning tower & Scrubber Jamshedpur, Flue Gas Plant PPV+VEF 2012 of Gas Cleaning plant for A/C: BF# I A: 1000 m 2 Jharkhand @ 1.2 mm EIMCO KCP Ltd. Coating of Launders of Gas Polyglass Gas Cleaning Cleaning plant. A/C: Rourkela Flue Gas PPV+VEF 2012 A: 85 m 2 Plant Steel Plant, Orissa @ 1.2 mm Tata Steel Ltd., Polyglass Stove & Dome internal Stove Dome Jamshedpur, 3 nos., A: 3300 m 2 PPV+VEF Flue Gas 2012 A/C: BF# F Jharkhand @ 1 mm Polyglass Additional Stove Dome JSW Steel Ltd., Stove Dome internal Flue Gas PPV+VEF 2012 Hospet, Karnataka A/C: BF# 3 & 4 A: 3000 m 2 @ 1 mm Coating of Demister vessel, Gas Cleaning Polyglass JSW Steel Ltd., conditioning tower & Scrubber 2010 – 11 Flue Gas Plant PPV+VEF of Gas Cleaning plant. Hospet, Karnataka A/C: BF# 4 A: 2000 m 2 @ 1.2 mm Coating of Demister vessel, Paul Worth Gas Cleaning conditioning tower & Scrubber Polyglass VEF 2009 – 10 A/C: Bokaro Steel, Flue Gas of Gas Cleaning plant. Plant @ 1.2 mm A: 824 m 2 Jharkhand Coating of Demister vessel, Gas Cleaning Polyglass VEF JSW Steel Ltd., conditioning tower & Scrubber Flue Gas Plant + Armagel VE 2008 of Gas Cleaning plant. Hospet, Karnataka A/C: BF# 3 A: 2000 m 2 @ 2.25 mm Alsthom Projects Gas Scrubber in Anode Bake Anode Bake Polyglass VEF Plant. A/C: Nalco, Angul, Flue Gas 2008 Plant A: 600 m 2 @ 1.2 mm Orissa Stove Domes internal, Stove Dome JSW Steel Ltd., Polyglass VEF 2007 – 08 Flue Gas A: 5000 m 2 A/C: BF# 3 Hospet, Karnataka @ 1 mm This is a proprietary document of Kirloskar Corrocoat Private Limited Page 11

REFERENCE LIST Service Product Year of Customer Equipment Work Description Condition Applied work Posco Coating of Demister A/C: IISCO, Gas Cleaning vessel, conditioning tower Polyglass VEF 2010 – 11 Flue Gas Burnpur, Plant & Scrubber @ 1.2 mm of Gas Cleaning West Bengal Internal Coating of Stove Polyglass JSW Steel Ltd., Stove Dome A/C: Dome. Flue Gas PPV+VEF 2011 Hospet, Karnataka BF# 4 A: 5000 m 2 @ 1 mm Industrial External surface of Plasmet ZF+ZE Gas pipeline. D: 1.2 Corrosive Pipeline 2010 @ 375 microns m to 3 m. A: 1600 TISCO, Gases m 2 Jamshedpur, Coating of Demister Jharkhand Gas Cleaning vessel, conditioning tower Polyglass VEF 2009 – 10 Flue Gas Plant & Scrubber @ 1.2 mm of Gas Cleaning Gas Scrubber in Anode Corroglass Bake Plant. Balco, Korba, MP Flue Gas Anode Bake Plant 2007 A: 500 m 2 HN4 @ 1.2 mm Coating of Demister Bhilai Steel Plant, Gas Cleaning vessel, conditioning tower Polyglass VEF Flue Gas 2006 & Scrubber of Gas Bhilai, MP Plant @ 1.2 mm Cleaning plant. A: 600 m 2 Gas Scrubber in Anode Hindalco, Gas Cleaning Corroglass 2004 – 05 Flue Gas Bake Plant. A: 500 m 2 Renukoot, UP Plant HN4 Gas Scrubber in anode Gas Cleaning Corroglass 2004 – 05 Bake Plant. A: 500 m 2 Balco, Korba, MP Flue Gas Plant HN4 @ 1.2 mm 1999 – Rain Calcining Sea Polyglass HA Valves 300 mm BFV 2nos. Ltd., Vizag, AP Water @ 1 mm 2000 TISCO, Corroglass WR 1994 – 95 Jamshedpur, Coal Coal Chutes Coal Chutes @ 3 mm Jharkhand This is a proprietary document of Kirloskar Corrocoat Private Limited Page 12

Recommend

More recommend