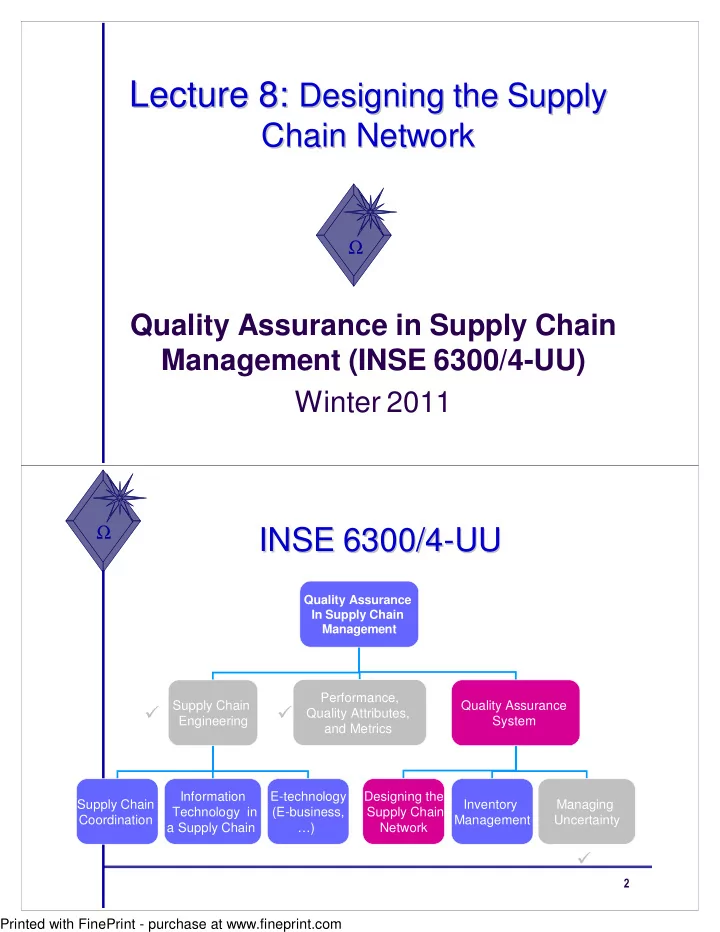

Lecture 8: Designing the Supply Lecture 8: Designing the Supply Chain Network Chain Network Ω Quality Assurance in Supply Chain Management (INSE 6300/4-UU) Winter 2011 Ω INSE 6300/4- -UU UU INSE 6300/4 Quality Assurance In Supply Chain Management Performance, Supply Chain Quality Assurance � � Quality Attributes, Engineering System and Metrics Information E-technology Designing the Supply Chain Inventory Managing Technology in (E-business, Supply Chain Coordination Management Uncertainty a Supply Chain …) Network � � Printed with FinePrint - purchase at www.fineprint.com

Ω Key Quality Issues Key Quality Issues Network Inventory Distribution Planning Control Strategies Supply Chain Information Decision- Quality Issues Technology Support Sys Integration Outsourcing Product & Partnering Strategies Design � Ω Overview Overview � Factors Influencing Distribution Network Design � Design Options for a Distribution Network � Printed with FinePrint - purchase at www.fineprint.com

The Supply Chain Network The Supply Chain Network Ω � The Role of Distribution The Role of Distribution Ω in the Supply Chain in the Supply Chain � Distribution: the steps taken to move and store a product from the supplier stage to the customer stage in a supply chain � Distribution directly affects cost and therefore drives profitability � Choice of distribution network can achieve supply chain objectives from low cost to high responsiveness � Examples: Wal-Mart, Dell, Proctor & Gamble, Grainger � Printed with FinePrint - purchase at www.fineprint.com

Factors Influencing Factors Influencing Ω Distribution Network Design Distribution Network Design � Distribution network performance evaluated along two dimensions at the highest level: � Customer needs that are met � Cost of meeting customer needs � Distribution network design options must therefore be compared according to their impact on customer service and the cost to provide this level of service � Factors Influencing Factors Influencing Ω Distribution Network Design Distribution Network Design � Elements of customer service influenced by network structure: � Response time � Product variety � Product availability � Order visibility � Returnability � Supply chain costs affected by network structure: � Inventories � Transportation � Facilities and handling � Information � Printed with FinePrint - purchase at www.fineprint.com

Relationship between Number of Relationship between Number of ٠Facilities and Response Time Facilities and Response Time Number of Facilities Response Time � Relationship between Inventory Costs Relationship between Inventory Costs ٠and Number of Facilities and Number of Facilities Inventory Costs Number of Facilities �� Printed with FinePrint - purchase at www.fineprint.com

Relationship between Transportation Relationship between Transportation ٠Costs and Number of Facilities Costs and Number of Facilities Transportation Costs Number of Facilities �� Facility Costs Relationship between Facility Costs Relationship between ٠and Number of Facilities and Number of Facilities Facility Costs Number of Facilities �� Printed with FinePrint - purchase at www.fineprint.com

Relationship between Total Logistics Relationship between Total Logistics Costs, Response Time and Number of Costs, Response Time and Number of ٠facilities facilities Response Time Total Logistics Costs Number of Facilities �� ٠Overview Overview � � Factors Influencing Distribution Network Design � Design Options for a Distribution Network �� Printed with FinePrint - purchase at www.fineprint.com

Classification of Distribution Classification of Distribution ٠Networks Networks 1. Manufacturer Storage with Direct Shipping 2. Manufacturer Storage with Direct Shipping and In-Transit Merge 3. Distributor Storage with Carrier Delivery 4. Distributor Storage with Last Mile Delivery 5. Manufacturer or Distributor Storage with Consumer Pickup 6. Retail Storage with Consumer Pickup �� 1. Manufacturer Storage with 1. Manufacturer Storage with ٠Direct Shipping (drop- -shipping) shipping) Direct Shipping (drop Manufacturer Retailer Customers Product Flow Information Flow �� Printed with FinePrint - purchase at www.fineprint.com

1. Manufacturer Storage with 1. Manufacturer Storage with ٠Direct Shipping (drop- -shipping) shipping) Direct Shipping (drop � Product is shipped directly from the manufacturer to the end user � The retailer takes the order and initiates the delivery request (information flow) � The retailer does not hold the inventory, which is centralized at the manufacturer � The supply chain can provide a high level of product availability with lower levels of inventories �� 1. Manufacturer Storage with 1. Manufacturer Storage with ٠Direct Shipping (drop- -shipping) shipping) Direct Shipping (drop � The manufacturer can allocate at least a portion of the available inventory across retailers on an as-needed basis � Postponement-based drop-shipping allows the inventory to be low � Dell strategy: build-to-order � Used for high-value, low and unpredictable demand items �� Printed with FinePrint - purchase at www.fineprint.com

1. Manufacturer Storage with 1. Manufacturer Storage with ٠Direct Shipping (drop- -shipping) shipping) Direct Shipping (drop � Inventory costs are low (thanks to aggregation) � Transportation costs are high: � The outbound distance to the customer is large � Package carriers have high shipping costs compared to truckloads � Lower facility costs thanks to aggregation � Response time is long: order transmission + shipping distances � The handling of returns is expensive: each order may involve shipment from different manufacturers � Significant investment in information infrastructure �� 1. Manufacturer Storage with Direct 1. Manufacturer Storage with Direct ٠Shipping (drop- -shipping) shipping) Shipping (drop �� Printed with FinePrint - purchase at www.fineprint.com

2. In- -Transit Merge Network Transit Merge Network 2. In ٠Factories In-Transit Merge by Retailer Carrier Customers Product Flow Information Flow �� 2. In- -Transit Merge Network Transit Merge Network 2. In ٠� Combining pieces of the order coming from different locations: � The customer gets a single delivery: Dell strategy � Transportation costs are lower than with drop- shipping � A coordination between manufacturers is needed � Suitable for high value items with low to medium demand � Can be used when the number of manufacturers is limited �� Printed with FinePrint - purchase at www.fineprint.com

2. In- -Transit Merge Network Transit Merge Network 2. In ٠�� 3. Distributor Storage with Carrier 3. Distributor Storage with Carrier ٠Delivery Delivery Factories Warehouse Storage by Distributor/Retailer Customers Product Flow Information Flow �� Printed with FinePrint - purchase at www.fineprint.com

3. Distributor Storage with Carrier 3. Distributor Storage with Carrier ٠Delivery Delivery � Inventory is not held by manufacturers but by distributors/retailers � Package carriers are used to transport products from the distributor/retailer to the customer � Can be combined with drop-shipping: Amazon strategy � High level of inventory because of demand uncertainty � Suitable for medium to fast moving products with high demand �� 3. Distributor Storage with Carrier 3. Distributor Storage with Carrier ٠Delivery Delivery � Transportation costs are lower compared to manufacturer storage: � Warehouses are closer to the customer and p ackage carriers are used � Facility costs are higher � Response time is better because warehouses are closer to customers � Returnability is easier �� Printed with FinePrint - purchase at www.fineprint.com

3. Distributor Storage with Carrier 3. Distributor Storage with Carrier Ω Delivery Delivery �� 4. Distributor Storage with Last 4. Distributor Storage with Last Ω Mile Delivery Mile Delivery Factories Distributor/Retailer Warehouse Customer’s home Product Flow Information Flow �� Printed with FinePrint - purchase at www.fineprint.com

4. Distributor Storage with Last 4. Distributor Storage with Last Ω Mile Delivery Mile Delivery � Distributors/retailers deliver the product to the customer’s home � The warehouse must be closer to the customer compared to the package carrier delivery � More warehouses are required � Higher levels of inventories � Suitable for fast moving items �� 4. Distributor Storage with Last 4. Distributor Storage with Last Ω Mile Delivery Mile Delivery � Transportation costs are the highest compared to the other options � Facility costs are very high � Response time is very quick � Returnability is easier to implement �� Printed with FinePrint - purchase at www.fineprint.com

4. Distributor Storage with Last 4. Distributor Storage with Last ٠Mile Delivery Mile Delivery �� 5. Manufacturer or Distributor Storage 5. Manufacturer or Distributor Storage with Customer Pickup with Customer Pickup ٠Factories Cross Dock DC Retailer Pickup Sites Customers Customer Flow Information Flow Product Flow �� Printed with FinePrint - purchase at www.fineprint.com

Recommend

More recommend