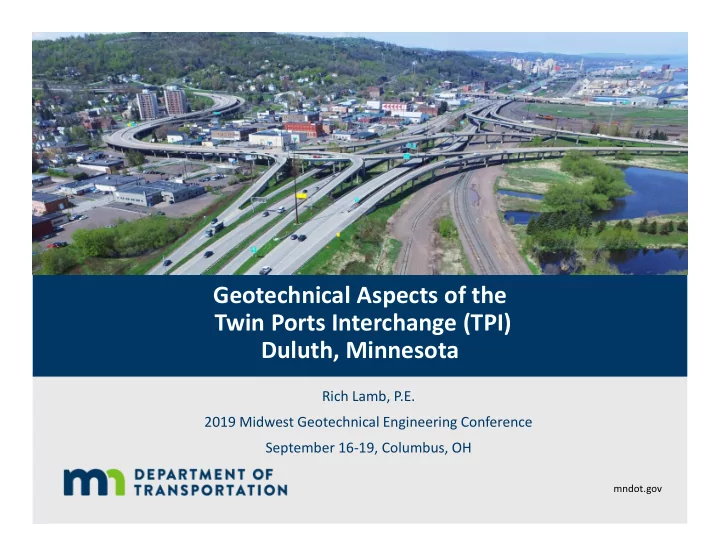

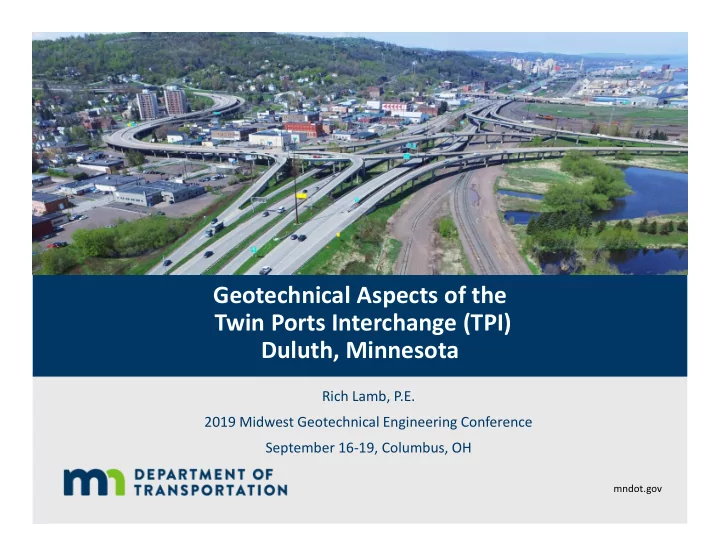

Geotechnical Aspects of the Twin Ports Interchange (TPI) Duluth, Minnesota Rich Lamb, P.E. 2019 Midwest Geotechnical Engineering Conference September 16-19, Columbus, OH mndot.gov

Sorry, Wisconsin

Project Location Duluth, Minnesota 2 Lake 1 Superior 3 Port of Duluth-Superior Superior, Wisconsin

Current Interchange • Known locally as the “Can of Worms” • 3 rd highest crash rate statewide for interchanges • 33 aging bridges (built in late ‘60’s), mainline interstate on land bridge • 16 bridges weight restricted 7 non- redundant • Problem for over-sized and over-weight traffic coming from port and getting on Interstate 4

Routes of Diverted OSOW Traffic 5

Current Main Interchange Historic Neighborhood I535 Lake Superior 6

Trestle Bridges (mainline I35 and all ramps) 7

US53 8

Garfield Interchange I535 9

Twin Ports Interchange (TPI) Project Goals • Enhance safety by eliminating blind merges and left exits • Replace aging infrastructure • Reduce maintenance and closures • Reduce bridge structure • Improve freight mobility • Allow oversize/overweight freight on the Interstate by reconstruct/rehab substandard bridges 10

Project Overview • Alternate Deliver Method - Construction Manager/General Contractor (CMGC) • Currently nearing 60% design status • Consultant design for both roadway and bridges • Construction scheduled for 2020-2022 ($250- 300M) • Driven Pile Load testing and Column Test Project (Rigid Inclusions) currently underway 11

Construction Manager/General Contractor (CMGC) • Contractor hired at start of design under professional/technical consultant contract • Contractor responsibilities • Constructability Reviews • Maintenance of Traffic, Construction Staging Reviews • Work will be let in two Work Packages • Three cost estimates (EE, Contractor, ICE) must be close for Contractor to do work 12

Current Design Layout • 14 New Bridges, 4 Bridge Rehabs • ~600,000 sq. ft. of Column Supported Embankments • Fill heights up to 38 ft. • 40% reduction in bridge deck area • 8,000 L.F. Retaining Walls • Cast-in-Place Concrete Cantilever • MSE 13

Geotechnical Design Team • Subsurface Investigations, Ret Wall Geotechnical Reports, Roadway Soils • Ground Improvement Design, Modeling • Supplemental Subsurface Investigations • Early work on TH 53 Embankments • Lateral Pile Stability mndot.gov/

Column Supported Embankment Design • Designed by consultants (Barr Engineering and Itasca Engineering) • Most economical column is full displacement grouted column • Diameters 16-18 in. • Column Spacing 8-10 ft. • Rough Unit Cost ~ $40/sq. ft. • Includes wall cost 15

Subsurface Investigations • 120 Historic Borings from 1960’s (poorly located, ±50 ft.) • 150 Cone Penetration Test (CPT) soundings • 250 Modern SPT Foundation Borings • Dozen or so Test Pits 16

General Subsurface Conditions US 53 Garfield Interchange Main Intersection Sand fill Sand fill Clay 10-55 ft. Org Silty Stiff Silt and thick Clay Clay Dense Sand Very Dense Sand Dense Sand >150 ft. Clay 40-60 ft Var. Bedrock Vert Dense Sand/Silt 100 ft. Bedrock 150 ft. 9/24/2019 mndot.gov 17

Soil Variability 9/24/2019 mndot.gov 18

Soil Variability Bridge 69902 West Abut Miller Creek Culvert Inlet 54 ft. 41 ft. 107 ft. 35 ft. 9/24/2019 mndot.gov 19

Sloping Bedrock 500 ft. Miller/Coffee Creek Culvet 90 ft. Bedrock 9/24/2019 mndot.gov 20

3D Soil Model 21

High Ground Water Table Existing Grade ~606 Lake Superior 603.5 MSL 22

Lake Tides • Strong North Wind = 1-2 “tide” 23

Soil Contamination 24

Soil Contamination • Petroleum, lead, arsenic, PAH, Asbestos 25

Big Geotechnical Challenges • Avoiding any excavation to limit cost of treating contaminated soil and groundwater • Possible Steel Corrosion from contaminated soil • Construction Staging does not allow for embankment settlement wait periods • High groundwater • Urban fill 26

Bigger Geotechnical Challenges • Interaction of CSE foundation elements with bridge/wall driven piles • Ground heave/lateral displacement from “forest” of full displacement columns • Low fill ground improvement • Building bridge/walls/embankments over in- place utilities • Reviewing designs using finite difference method 27

Low Embankments • No excavation • No settlement wait periods 4-6 ft. fill • 1 inch of long term allowable settlement Weak Soils, highly contaminated 30-60 ft. Dense Soils 9/24/2019 mndot.gov 28 28

Low Embankment Foundation Design • Columns Supported Embankment • Driven piles or grouted 4-6 ft. fill columns LTP • 10 ft. center spacing • 1 ft. thick reinforced concrete LTP Dense Soils 9/24/2019 mndot.gov 29 29

Interaction of CSE columns and bridge piles 30

Ground Heave/Lateral Displacement Problem Full Displacement Columns Driven Piles 9/24/2019 mndot.gov 31

Column Test Project • 63 CMC column 18 in. dia. 65 ft. • Wick drains ½ area • Driven 16 in. pipe pile • Two Static Load Tests on columns • Instruments 9/24/2019 mndot.gov 32

Column Test Layout 33

Test Area Soils 65 ft. 9/24/2019 mndot.gov 34

Column Test Embankment 9/24/2019 mndot.gov 35

Instrumentation • 63 total gages • Piezometers • Survey targets • Extensometers • ShapeAccelArray • Vertical and horizontal • Strain Gages 9/24/2019 mndot.gov 36

Initial Instrumentation Results 37

Current Instrumentation Results • Lateral Deflections ~4 inches near columns (3 ft), but only ½ inch 10 ft. away • Heave – 1 inch • Pore Pressures – dissipates quickly 38

Vertical SAA 39

If Ground Movement is Problem • Use non-displacement columns or H pile in “buffer zones” Full Auger Cast Displacement or H Pile Columns 2 3 1 9/24/2019 mndot.gov 40

Sanitary Lift Station 41

42

43

Cross Section 44

Options • Remove building • Fill-in basement and drill foundations through floor • Span over 45

Bridge Piling Adjustments 46

Reviewing CSE Designs • How to check 2d, 2.5d and 3d Finite Difference Method models 47

Thank you Rich Lamb rich.lamb@state.mn.us 651-366-5595 9/24/2019 mndot.gov 48

49

Column Supported Embankments 101 Embankment Load Transfer Platform Rigid Inclusions Weak Soils (columns/piles) (70-95% of embankment load) Dense Soils 9/24/2019 mndot.gov 50

Rigid Inclusions (Columns or Piles) • Full Displacement Grout Columns $12-$20 / LF • Non-displacement Grout Columns • Driven piles • H sections $30-$40 / LF • Pipe sections • Typical Spacing 5-10 ft. centers • Pile Caps typically used 9/24/2019 mndot.gov 51

52

CSE with misc Structures/Utilities OH Sign Exit 535 EB Light Tower Embankment CIP Wall MSE Wall Storm Sewer 9/24/2019 mndot.gov 53

Archaeological Concerns • I-535 and Garfield Avenue • Brown’s Trading Post • North side of Piedmont Avenue • Known Native Cemetery • Some graves relocated in 1870 to Railyard • Coffee Creek Banks • Culvert built over stream and filled • Beneath the structure • Old Lakeshore • Drilling in these areas suspended 54

Load Transfer Platform Design • Acts as a pile cap – evenly distributes load to columns • Select well graded granular fill (94-98% compaction) (MnDOT Class 5) • Minimum of three horizontal biaxial geosynthetic reinforcement layers with vertical spacing of 8-18 in. • LTP thickness (½ the clear span between columns) 9/24/2019 mndot.gov 55

Full Displacement Columns • “Drilled Displacement Piles” • Very few spoils, low noise, vibration • Reverse flight Augers push soils down and away from column • May displace soils laterally – problem for adjacent structures • Diameters of 12-24 inches, and typical lengths of 65-85 ft. • Difficult to penetrate dense soil layers 9/24/2019 mndot.gov 56

Menard – Controlled Modulus Column 9/24/2019 mndot.gov 57

Non Displacement Columns • “Auger Cast Pile” or “Continuous Flight Auger Pile” • Diameters of 12-24 in. • Depths of 100 ft. or more • Low noise, vibration • Spoils much greater than FDC 9/24/2019 mndot.gov 58

Displacement Piles 9/24/2019 mndot.gov 59

Non-Displacement Piles • “Pile Supported Embankment” 9/24/2019 mndot.gov 60

Questions or Comments?

Geology • What has shaped the subsurface conditions the project site? • Volcanoes (igneous bedrock) • Glaciers (dense soils) • Lake Sediments (organics and soft clay) • Erosion from stream flow (variability) • Land use (surface fill material, contaminants) mndot.gov/

Subsurface Investigations • 120 Historical Borings (1960s) (bridges) • 100 Modern Borings (AET) (bridges) • 150 Cone Penetration Test (CPT) Soundings 75-100’ (embankments) • 150 Future holes 9/24/2019 mndot.gov 63

64

65

66

Recommend

More recommend