2019/07/12 1

2019/07/1 Group structure of NAMWOLL 2 Organogram INCUBEX MINERALS LTD 100% 100% Siyaghopa Namaqua Processing Trading 147 Wollastonite Plant (Pty) Ltd (Pty) Ltd 100% Rainbow House Properties 108 (Pty)Ltd Mining Right

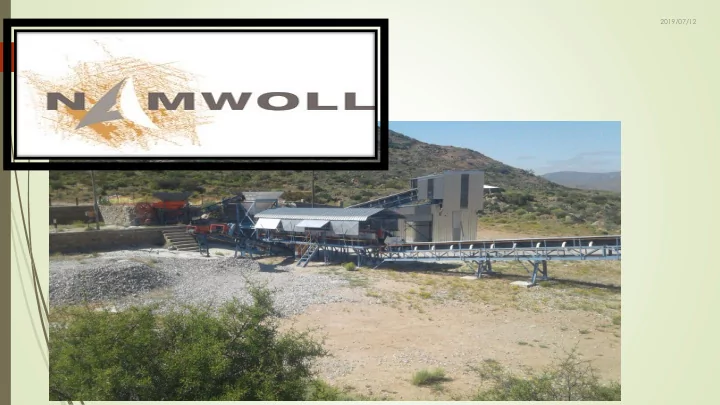

About Namwoll 2019/07/12 3 Incubex Minerals Ltd (“Incubex”) is the investment and holding company of Namaqua Wollastonite (Pty) Ltd and Siyaghopa ➢ Trading 147 (Pty) Ltd. Siyaghopa Trading 147 (Pty) Ltd is the operating company and Namaqua Wollastonite (Pty)Ltd is the holder of the mining right. The operation, referred herein as “Namwoll”, has been in operation since 2013. Incubex bought The three companies now ➢ referred to as Namwoll during 2013 and has since re-established the Processing Operation (Siyaghopa Trading 147 (PTY) Ltd) and the Magata Mine (Namaqua Wollastonite (PTY) Ltd). ➢ Namwoll is a small operation with a large deposit and future prospects higher production for export, it is further the only operating wollastonite mine in South Africa. Namaqua Wollastonite (Pty) Ltd holds the mining right as well as a prospecting right situated next to the mining right area. ➢ The mine is situated 18km out of Garies, Northern Cape, with the fine product processing plant in Garies. ➢ It is a open pit mine and uses a dry separation process. ➢ ➢ Namwoll currently produces 9 different sizes of Wollastonite product being -25mic, -100mic, -150mic, 20#, <850mic, -1200mic, 0.5-3.0mm, and -5mm. Life of mine at current production is over 1000years. Magat Mine has 1 million tonnes drilled reserves with an estimated total ➢ reserves of 3 million tonnes.

2019/07/12 The Namwoll Team 4 The Team Bruce Stride – Managing Director; ➢ Riana Mulder – Personal Assistant to MD and sales and marketing ➢ manager.; Erin Markgraaff – Accountant; ➢ Gerrit Visser – Mine Subordinate manager and process systems ➢ supervisor.

Objectives 5 Long Term Objectives: Short Term Objectives: Expand plant to produce at least1000 Make production more efficient and tonnes a month which will lower our cut down on costs; unit cost; Increase volumes produced to 150 Take over the entire South African tonnes; Market; Marketing drive to increase the current Export product to Africa and Europe. Sales to 150tonnes a month in order for the company to reach break-even. Settle SARS debt; Reach break-even by December 2019; Finalise Feasibility Study on expansion. 2019/07/12

2019/07/12 The Mining process 6 Mine Pit Truck Loading Bin Crushing and Screening Plant Wollastonite Processing Plant

2019/07/12 What is Wollastonite 7 ➢ Wollastonite is named after the English chemist and mineralogist William Hyde Wollaston (1766 – 1828) and is a calcium inosilicate mineral ( CaSiOɜ ) that may contain small amounts of iron, magnesium, and manganese substituting for calcium. It is usually white but also found in a pearly grey colour. ➢ It forms when impure limestone or dolostone is subjected to high temperature and pressure sometimes in the presence of silica-bearing ➢ fluids as in skarns or contact metamorphic rocks. Associated minerals include garnets, vesuvianite, diopside, tremolite, epidote, plagioclase feldspar, pyroxene and calcite. Some of the properties that make wollastonite so useful are its high brightness and whiteness, low moisture and oil absorption, low volatility and enhancement of flexural and compaction strengh. ➢ Wollastonite is used primarily in ceramics, friction products (brakes and clutches), metal making, paint filler and plastics. ➢ Despite its chemical similarity to the compositional spectrum of the pyroxene group of minerals where magnesium and iron substitution for calcium ends with diopside and hedenbergite respectively it is structurally very different, with a third SiO 4 tetrahedron in the linked chain (as opposed to two in the pyroxenes).

2019/07/12 How does wollastonite look 8 Wollastonite in nature. Cluster of crystals Wollastonite in nature. Fine Crystals. Wollastonite cluster. with carnet and dioptase inclusions. Wollastonite cluster. Wollastonite needles under a Wollastonite end product. microscope.

2019/07/12 Wollastonite Specifications 9 1. GENERAL ➢ Category - Silicate Mineral ➢ Formula - Calcium Silicate, CaSiO 3 ➢ Strunz Classification – 09.DG.05 ➢ Crystal System - Triclinic, monoclinic polytype exists ➢ Unit Cell - a = 7.925 Å, b = 7.32 Å, c = 7.065 Å; α = 90.055 ° , β = 95.217 ° , γ = 103.42 ° ; Z = 6 2. IDENTIFICATION ➢ Colour – White, colourless or grey ➢ Crystal habit – Rare as tabular crystals commonly massive in lamellar, radiating, compact and fibrous aggregates ➢ Crystal Symmetry - Triclinic – pinacoidal H-M symbol: 1 Space group: P1 (1A polytype) ➢ Twinning – Common ➢ Cleavage – Perfect in two directions at near 90 ˚ ➢ Fracture – Splintery to uneven ➢ Luster – Vitreous or dull to pearly on cleavage surfaces ➢ Solubility – Soluble in HCI, insoluble in water

2019/07/12 Wollastonite Uses 10 ➢ Wollastonite has industrial importance worldwide. It is used in many industries, mostly by tile factories which have incorporated it into the manufacturing of ceramic to improve many aspects, and this is due to its fluxing properties, freedom from volatile constituents, whiteness, and acicular particle shape. In some industries, it is used in different percentages of impurities, such as its use as a fabricator of mineral wool insulation or as an ornamental building material. ➢ In ceramics, wollastonite decreases shrinkage and gas evolution during firing, increases green and fired strength, maintains brightness during firing, permits fast firing, and reduces crazing, cracking and glaze defects. ➢ In metallurgical applications, wollastonite serves as a flux for welding, a source for calcium oxide, a slag conditioner, and to protect the surface of molten metal during the continuous casting of steel. ➢ As an additive in paint, it improves the durability of the paint film, acts as a pH buffer, improves its resistance to weathering, reduces gloss, reduces pigment consumption and acts as a flatting and suspending agent. ➢ In plastics, wollastonite improves tensile and flexural strength, reduces resin consumption, and improves thermal and dimensional stability at elevated temperatures. ➢ Surface treatments are used to improve the adhesion between the wollastonite and the polymers to which it is added. ➢ As a substitute for asbestos in floor tiles, friction products, insulating board and panels, paint, plastics, and roofing products, wollastonite is resistant to chemical attack, inert, stable at high temperatures and improves flexural and tensile strength. ➢ Plastics and rubber applications were estimated to account for 25% to 35% of U.S. sales in 2009, followed by ceramics with 20% to 25%; paint, 10% to 15%; metallurgical applications, 10% to 15%; friction products, 10% to 15%; and miscellaneous, 10% to 15%. Ceramic applications probably account for 30% to 40% of wollastonite sales worldwide, followed by polymers (plastics and rubber) with 30% to 35% of sales, and paint with 10% to 15% of sales. The remaining sales were for construction, friction products, and metallurgical applications.

2019/07/12 Wollastonite Application and Function 11 Application Field Specific Application Wollastonite Function Ceramic Industry Various ceramics, glass and moulds Reduce the burnt temperature; • Shorten the burnt period; • Reduce the firing shrinkage. Improve deflection and cracking; • Optimisation of porcelain glaze glossiness and sleek flatness; • Improve the mechanical strength abrasion and scratch resistance. • Metallurgical Industry Protection slag for heat insulation Ensuring composition stabilized and uniformity of slag; • material and cast steel Better adapted to steel types; • Reducing the possibility of steel surface embrittlement and longitudinal cracking; • Strong absorbsion and dissolving capacity of impurity; • The viscosity varies little along with temperature in the process of continues casting; • Lubrication and protection without effecting the crystallisation and cooling of casting billet; • Reduces fluoride pollution and equipment corrosion. • Building Materials Industry Calcium silicon plate, cement fibrolite Being innocuous, flavourless and non-radioactive it reduces pollution and production costs; • plate, fire insulation board Increases shock resistance, flexural strength and abrasive resistance; • Good corrosion resistance, sound and heat insulation and fireproofing. • Rubber and Plastics Industry Styrene butadiene rubber Increases wear and scratch resistance; • Increases shock strength and enables products to enjoy high electrical and thermal insulation; • Increases thermal and dimensional stability; • Increases surface finish quality; • Good reinforcing function; • Increases the tensile strength, tearing strength, elongation at break, wear resistance; • Improves moistening and dispersion. • Coating and Paint Industry Anticorrosive paint, thermal insulation Wear, corrosion and ultra violet resistance; • coating, construction paint Make paint show higher surface gloss and better water proof corrosion and buffers ph-value; • Improve thermal stability; • Reduce consumption of cementing substance. •

Recommend

More recommend