Pump Design and Innovation (Pushing the Boundaries)

Bedford Pumps Ltd Contents: Who are we? High Head Sewage Pumps Minworth Altmouth Crossness Belfast How do we do it?

Who are we? Based in Bedford, England Established in 1987 by former members of W H Allen / Gwynnes Core business - Design and manufacture of large centrifugal pumps Ranges from 100 l/s to 12,000 l/s at 3m to 100m head Full M & E Capability We offer the complete “Engineered Solution”

High Head Sewage Pumps Traditional limit 70m head 100 Increase in transfer duties Need for higher heads Head (m) High speed pumps not 20 preferred 10 Two-stage pumping problematic 0 100 200 1000 5000 Flow (l/s) Developed 100m pump

High Head Sewage Pumps Maximum 4-pole speeds 100 Simplified hydraulic design Head (m) Easier to control 20 Reduced station size 10 Minimum 100mm solid sphere 0 100 200 1000 5000 Flow (l/s)

High Head Sewage Pumps Dover & Folkestone Pumping Stations unique in Europe due to high head capabilities Two sets of pumps in series, one wet well submersible, one dry well MFV Required to pump total of 155m in 94m & 61m stages (i.e. to the top of the White Cliffs of Dover) Much larger solids handling capabilities Improved previous blocking issues

High Head Sewage Pumps Lytham Transfer PS Three pumps (D/A/S) 325 l/s each 100m head 500 kW motors

High Head Sewage Pumps White Hoe PS (I.of.M.) Replaced problematic existing units Four units 260 l/s each 90m head Motors 350 kW

Minworth Settled Sewage Pumping Station Largest PS in Severn Trent Water region BPL invited to participate in design Free exchange of ideas No formal enquiry No specification Two years to completion

Minworth Settled Sewage Pumping Station Maximum flow 14,000 l/s BPL involved in all aspects of station design Six pumps installed Open-top canisters

Minworth Settled Sewage Pumping Station Total value £650k Pump Efficiency 89% Combined Efficiency 85.5% Motors 160 kW, 14-pole 424 rpm

Belfast Terminal Pumping Station

Belfast Terminal Pumping Station One of the biggest infrastructure projects in Northern Ireland Pumps fundamental to project Provide protection against a 1 in 30 year storm event Six large Storm Pumps and two smaller FFT Pumps supplied

Belfast Terminal Pumping Station Shaft 40m Deep 36m Diameter High Grit Content Maximum Storm Flow 18,000 l/s Head Range 10m to 36m Ensure a minimum self-cleansing velocity greater than 1.8 m/s

Belfast Terminal Pumping Station Traditional pumping method Bedford Pumps’ solution

Belfast Terminal Pumping Station Drive shaft & associated supports/bearings eliminated Overall cost of installation minimised Low capital and maintenance costs

Belfast Terminal Pumping Station Storm Pumps 3,500 l/s each Heads up to 36m 960 kW 3.3kV 490 rpm (fixed speed) Water Cooled Eex n Temp T3 IP68

Belfast Terminal Pumping Station DWF Pumps 750 l/s each Heads up to 41m 370 kW 400 V 780 rpm (V. speed) Water Cooled Eex n Temp T3 IP68

Crossness One of Thames Water’s largest STW’s Contract value £1.5m Replacing 50 year old Allen Gwynne pumps 13 pumps replaced with new drywell submersible pumps Low Level – 650 kW High Level – 270 kW Transfer – 130 kW

Crossness All pumps 180mm diameter solids handling Eliminate solid drive shafting Variable speed optimised to give best LWLC

Altmouth Pumping Station Replacement of four Vickers 2.2m diameter Storm Pumps, 19.8 m3/s each Originally Diesel drive via David Brown Gearbox £4m M&E contract. – BPL Principal Contractor

Altmouth Pumping Station BPL involvement from 2005 Close discussion with EA & Halcrow Initial “new” design 3 pumps at 15m3/s each Similar arrangement anticipated

Altmouth Pumping Station BPL suggested 4 pumps rather than 3 Head reduced from 5m to 3.8m as a result Power reduced from 2940 kW to 2320 kW Canister pumps become a real possibility

Altmouth Pumping Station Design further enhanced by introduction of gearbox within the canister Motors now 6-pole rather than 26 – pole Motors 620 kW 3.3 kV

Altmouth Pumping Station Scope of Supply Pumps Motors Integral gearbox Canister 11kV & 415V Transformers Starters & Switchgear Cabling & Instrumentation Removal of existing plant Installation & commissioning

Altmouth Pumping Station All four pumps now installed & operating Two additional DWF Pumps added to contract

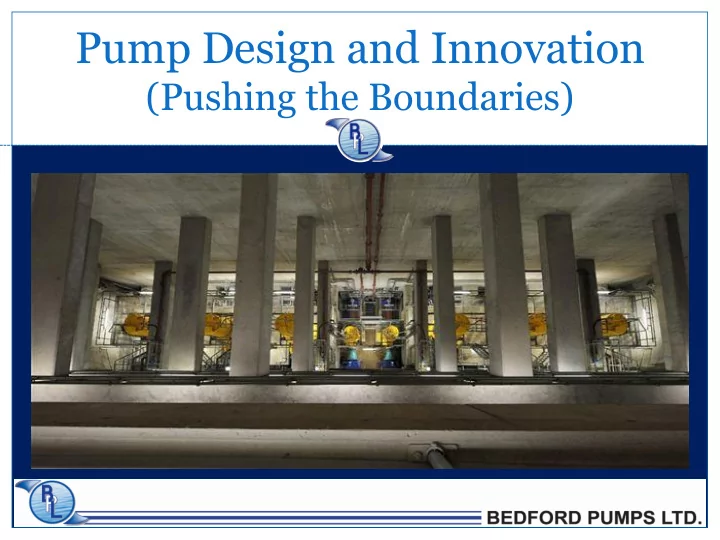

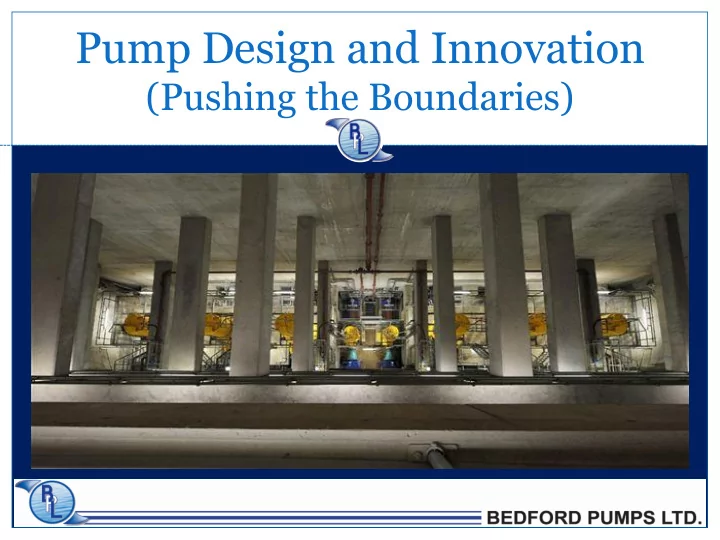

Altmouth Pumping Station

Altmouth Pumping Station

Altmouth Pumping Station

How do we do it? Company Size Flexibility in production Employees “Can Do” approach Open discussion And basically....

How do we do it? “...Any Colour You Like....”

An Acknowledgement “ We do these things not because they are easy, but because they are hard” John F. Kennedy, Sept 12 th 1962 We know that none of this happens without an element of risk. We also know we could not do this on our own. Full acknowledgment is due to those who have supported and helped us along the way.

Questions?

Recommend

More recommend