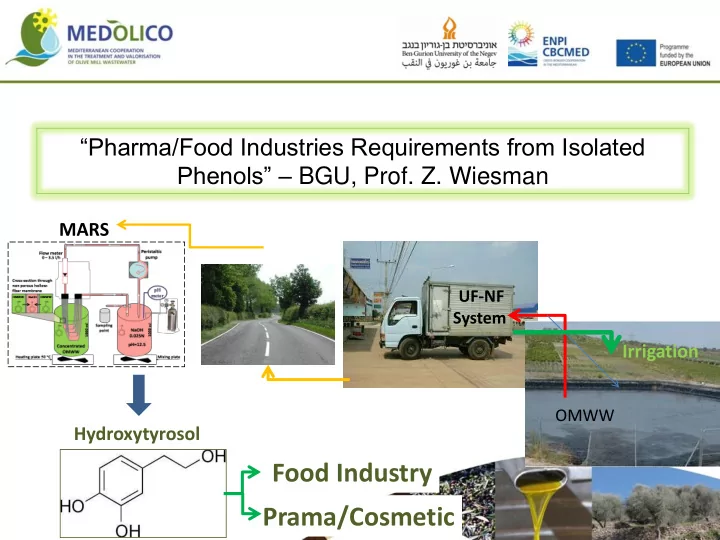

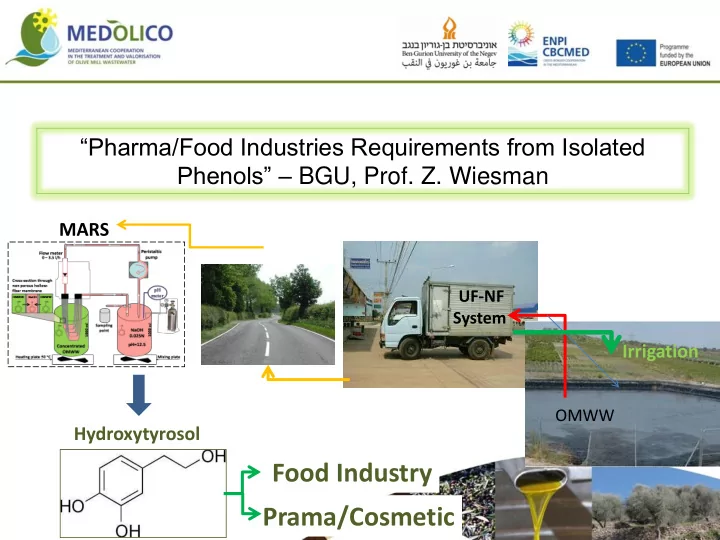

“Pharma/Food Industries Requirements from Isolated Phenols” – BGU, Prof. Z. Wiesman MARS UF-NF System Irrigation OMWW Hydroxytyrosol Food Industry Prama/Cosmetic

OMWW Polyphenols - Health Anti-oxidant Skin protectant Anti-atherogenic Oleuropein degradation Anti-microbial Anti-imflammatory Products - Polyphenols Anti-cancer Anti-aging Anti-viral

OMW Polyphenols by- products Oleuropein Tyrosol Apigenin Hydroxytyrosol Luteolin 4-Hydroxybenzoic acid Caffeic acid p-Cumaric acid Quercetin Gallic acid Cinnamic acid

Example of HT Bioactivity

COD ~ 106g/l Final -HT OMWW Phenol~ 3g/l Mobile OMWW + NMR~ 99% Pure product TP/TOCx100~8% Membrane Contractor Preparative Acidification PH 2 Pilot Plant HPLC Product B: Ultra- Food Pharma Filtration Additive Starting Material Product A: Nano- COD~10g/l Semi-purified Filtration Phenol~0.7 g/l H2O for Agri Hydroxytyrosol Enriched Organic HT/TOCx100~12% Phenol~4.5g/l Product Concentrate MA-HT-R (MARS -. HT Compost Organic Waste Recovery Sys.)

MS Fingerprints Hydroxytyrosol-TMS Tyrosol-TMS

Permeate – GC-MS Spectrum I.S

Sterlitech NF flat sheet module High P pump UF – NF System Membrane Contractor HT Recovery Sys.

NF – concentration of OMWW (sterlitech) 70 55 60 45 4.5 50 60 40 50 4 45 DK5 50 35 40 40 3.5 J J NF270 J, Flux, L/m2h J, Flux, L/m2h 40 30 35 DP Applied P, bar DP Applied P, bar 3 30 Sp. Flux, L/m2-h-bar 30 30 25 2.5 25 20 20 20 2 20 10 10 15 15 1.5 0 10 0 10 1 1 2 3 4 5 6 1 2 3 4 5 6 7 VCF VCF 0.5 DK5 – 7.1 L/m2-h-bar NF270 – 12.2 L/m2-h-bar 0 1 3 5 7 VCF

NF selectivity 120.0% RAHAT – OMWW after UF Initial rejection Final rejection 100.0% DK5 – passes only tyrosol and 80.0% hydroxytyrosol. Permeate was >99% tyrosol/hydroxytyrosol! 60.0% 40.0% 20.0% 0.0%

NF selectivity 120.0% NF-270 Final Rejn RAHAT 100.0% 80.0% NF-270 – not nearly as selective! 60.0% 40.0% 20.0% 0.0%

Mem. Contractor Hydroxytyrsol Recovery Sys. Dialysis cell for diffusion rate measurement

Food/ Pharma industries View & Basic Questions Regarding OMWW Islated Phenols: What is the PRODUCT? ( Food Additives; Pharma Drug Starting Material ) Production process? ( Combined Membrane Contractor Recovery Sys. - > Prep. HPLC ) Rate of purification; Quantities and Qualities? (~ 75 % Hydroxytyrosol ; ~ 4 , 500 ppm of high volume NF Concent . ) Market size & vision? ( Existing and Increasing Multi - Millions Market ) Chances to meet FDA Regulations? ( Food – Relatively High & Easy; Pharma – Higher Risk )

FDA Regulations Approach: Safety and nutritional quality of food sold. Scope includes: Food labelling, advertising and claims; Food standards and compositional requirements; Foods for special dietary uses; Food additives; Chemical and microbial hazards; Veterinary drug residues; Packaging material; Pesticides. The role of the FDA is to protect the public against health hazards and fraud from the sale of food (including beverages), drugs , medical devices and cosmetics .

Costs of Mobile OMWW Membrane Treatment System: System treating capacity of 50 m 3 per day. Main equipment cost (UF,NF,generator) +contactor facility – 202,000 € Electrical installation (including services) cost (for membrane contactor center) – 6000 € If there is a need for constructing a storage pond, estimated construction cost – 20,000 € Contingencies (5%) – 10,000 € Cost of 10-years rent for the land space that the treatment plant would occupy - Industrial park (100 m2): 1500 Euro/month, 15,000 Euro/year, 150,000 euro/10years In case that the land of the project will not be rented and will be purchased - 80,000 € Cost of electricity for 10 years of operation (based on 0.1 € per kWh -1 ) - 15.500 € Total Salaries of Employees for 10 years operation - 25000 € /year; 250,000 € /10 year period including operating the processing center for polyphenols. Rental cost of heavy vehicle 2000 euro/month x 2 months - 4,000 € /year Maintenance Cost for 10 years of operation (1% of capital, exclusive of membranes) – 20,000 € Membrane replacement costs during a period of 10 years of operation - 20.000 € Insurance Cost for 10 years of operation - 800 € Chemicals cost (acid and base and cleaning chemicals) for 10 years of operation - 57.000 € Value of recovered polyphenols that compensates costs – 150 € /kg X 688 kg/season =103,000 €

Recommend

More recommend