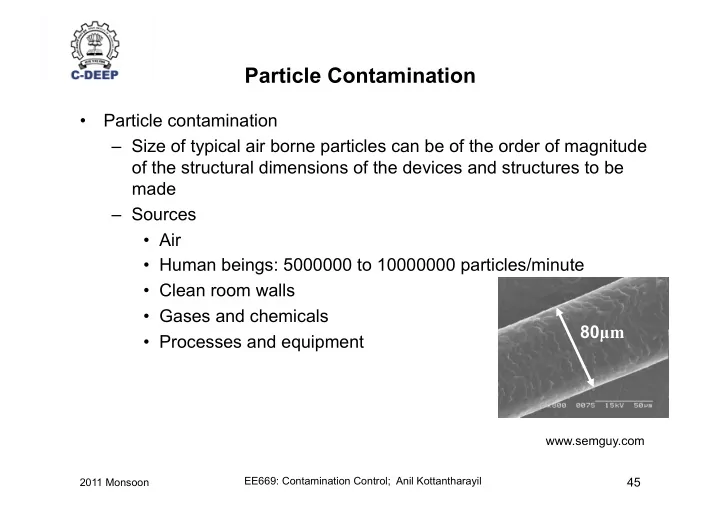

Particle Contamination • Particle contamination – Size of typical air borne particles can be of the order of magnitude of the structural dimensions of the devices and structures to be made – Sources • Air • Human beings: 5000000 to 10000000 particles/minute • Clean room walls • Gases and chemicals 80 µm • Processes and equipment www.semguy.com EE669: Contamination Control; Anil Kottantharayil 45 2011 Monsoon

Particle control: clean rooms HEPA filter: High Efficiency PArticulate filter. Minimum efficiency of particle removal = 99.97% ULPA filter: Ultra Low Penetration Air filter. Efficiency of 99.999% for ~0.1 to 0.2µm W. Whyte (ed.), Cleanroom Design, II nd edition, Wiley, 1991 EE669: Contamination Control; Anil Kottantharayil 46 2011 Monsoon

Particulate Filters Filter medium: glass fiber HEPA filter W. Whyte (ed.), Cleanroom Design, II nd edition, Wiley, 1991 EE669: Contamination Control; Anil Kottantharayil 47 2011 Monsoon

Clean room classification: ISO 14644-1 Definitions • Cleanroom or clean zone – room or zone in which the concentration of airborne particles is controlled, and which is used in a manner to minimize the introduction, generation, and retention of particles inside the room, and in which other relevant parameters, e.g. temperature, humidity and pressure are controlled as necessary • Classification – the process of specifying the level of airborne particulate, expressed in terms of an ISO Class N, which represents maximum allowable concentrations (in particles per cubic metre of air) for considered sizes of particles EE669: Contamination Control; Anil Kottantharayil 48 2011 Monsoon

Clean room classification: ISO 14644-1 Classification number (N) – 2.08 ⎛ ⎞ C n = 10 N 0.1 ⎜ ⎟ D ⎝ ⎠ where C n - is the maximum permitted concentration (in particles per cubic meter of air) of airborne particles that are equal to or larger than the considered particle size, D. C n is rounded to the nearest whole number. N – is the ISO classification number, which shall not exceed the value of 9. Intermediate ISO classification numbers may be specified with 0.1, the smallest permitted increment of N D – is the considered particle size in micrometers 0.1 – is a constant with dimensions of micrometers EE669: Contamination Control; Anil Kottantharayil 49 2011 Monsoon

Clean room classification: ISO 14644-1 Maximum Concentration (Cn) of Particles in Air {Particles in each cubic meter equal to or greater than the specified size ISO Class (D in µ m)} (N) Particles size > 0.1 µ m > 0.2 µ m > 0.3 µ m > 0.5 µ m > 1 µ m > 5 µ m ISO Class 1 10 2 ISO Class 2 100 24 10 4 ISO Class 3 1,000 237 102 35 8 ISO Class 4 10,000 2,370 1,020 352 83 ISO Class 5 100,000 23,700 10,200 3,520 832 29 ISO Class 6 1,000,000 237,000 102,000 35,200 8,320 293 ISO Class 7 352,000 83,200 2930 ISO Class 8 3,520,000 832,000 29,300 ISO Class 9 35,200,000 8,320,000 293,000 EE669: Contamination Control; Anil Kottantharayil 50 2011 Monsoon

Clean room design thumb rules ISO class Controls Air Velocity: Air changes Filter coverage % of FPM per hour ceiling (filter, air flow) 1 Stringent 70 - 130 > 750 100 (ULPA, UD) 2 Stringent 70 - 130 > 750 100 (ULPA, UD) 3 Stringent 70 - 130 > 750 100 (ULPA, UD) 4 Stringent 70 - 110 500 - 600 100 (ULPA, UD) 5 Stringent 70 - 90 150 - 400 100 (HEPA, UD) 6 Intermediate 25 - 40 60 - 100 33 – 40 (HEPA) 7 Intermediate 10 - 15 25 - 40 10 – 15 (HEPA) 8 Less Stringent 3 - 5 10 - 15 05 – 10 (HEPA) UD – unidirectional air flow W. Whyte (ed.), Cleanroom Design, II nd edition, Wiley, 1991 EE669: Contamination Control; Anil Kottantharayil 51 2011 Monsoon

CEN Cleanroom Design: CEN clean room 30% coverage HEPA Filters ISO 6/ 7 Clean room Heater Balancing Laminar Flow Return Damper Air Riser Pre-filters Air Blower Cooling Return Return Fresh Air Coils Air Air Damper ISO Class 6 Drawing courtesy: Prof. Richard Pinto, EE, IIT-B EE669: Contamination Control; Anil Kottantharayil 52 2011 Monsoon

Clean Room Layouts Ball room design Service chase Mini environment type W. Whyte (ed.), Cleanroom Design, II nd edition, Wiley, 1991 EE669: Contamination Control; Anil Kottantharayil 53 2011 Monsoon

Clean rooms: mini environment W. Whyte (ed.), Cleanroom Design, II nd edition, Wiley, 1991 EE669: Contamination Control; Anil Kottantharayil 54 2011 Monsoon

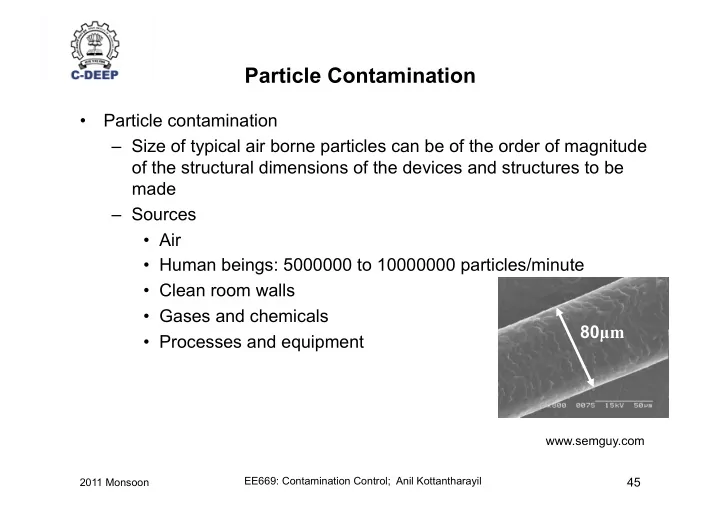

Particle Contamination • Particle contamination – Size of typical air borne particles can be of the order of magnitude of the structural dimensions of your devices and structures you make – Sources • Air • Human beings: 5000000 to 10000000 particles/minute • Clean room walls • Gases and chemicals 80 µm • Processes and equipment With permission from www.semguy.com EE669: Contamination Control; Anil Kottantharayil 55 2011 Monsoon

Particle Contamination: human beings in cleanrooms • All exposed parts of our body and cloths carry contaminants – Skin Fats, salts, bacteria & fungi – Exhalation – Hair Hair, particles & fibers – Apparel – Costumes • Wear lint free bunny suits, hair nets, goggles, hand gloves – do not expose any part of your body in clean rooms • Reduce the presence of human beings in clean rooms – more automation EE669: Contamination Control; Anil Kottantharayil 56 2011 Monsoon

Particle control requirements: example ITRS 2001 ITRS 2001 edition EE669: Contamination Control; Anil Kottantharayil 57 2011 Monsoon

Recommend

More recommend