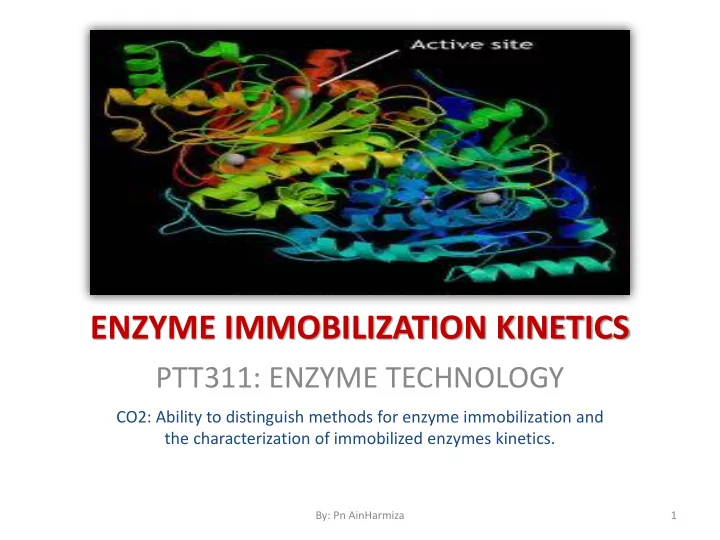

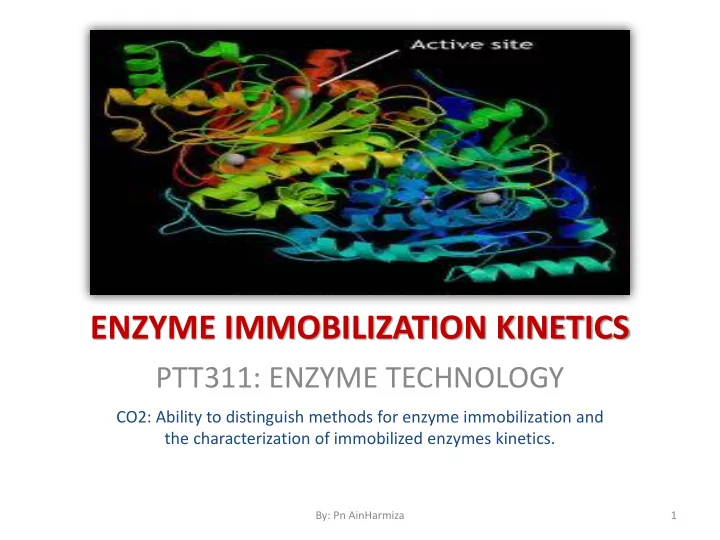

ENZYME IMMOBILIZATION KINETICS PTT311: ENZYME TECHNOLOGY CO2: Ability to distinguish methods for enzyme immobilization and the characterization of immobilized enzymes kinetics. By: Pn AinHarmiza 1

Immobilization of Enzymes • Consider the following two designs for a continuous enzyme process S P What are the advantages and disadvantages of PROCESS 2 compared to PROCESS 1 ? By: Pn AinHarmiza 2

ADVANTAGES DISADVANTAGES • • Enzyme is not lost after process An additional process (and cost) and might therefore be used for is associated with enzyme greater duration. immobilization. • • Enzyme does not need to be Enzymes may leak from separated from products. immobilized state. (Conversely, products do not • Diffusional limitations. need to be separated from Substrate(s) and product(s) must enzyme.) transfer across a boundary to get • Higher enzyme concentrations to/from active site. are attainable without sacrificing • Can be difficult to control these advantages. environment immediately • Some enzymes are more stable if affecting enzyme and its activity. they are immobilized. (Many • Some enzymes are less stable if native enzymes are they are immobilized. (Structural “immobilized” in the cell.) change). By: Pn AinHarmiza 3

How to reduce structural changes and prevent binding at activity site: 1. Mix enzyme with competitive inhibitor. 2. Immobilize. 3. Wash the competitive inhibitor away. By: Pn AinHarmiza 4

EFFECT OF MASS-TRANSFER RESISTANCE • The immobilization of enzymes may introduce a new problem which is absent in free soluble enzymes. • It is the mass-transfer resistance due to the large particle size of immobilized enzyme or due to the inclusion of enzymes in polymeric matrix. By: Pn AinHarmiza 5

EFFECT OF MASS-TRANSFER RESISTANCE • If we follow the hypothetical path of a substrate from the liquid to the reaction site in an immobilized enzyme, it can be divided into several steps (Figure 3.2): 1. transfer from the bulk liquid to a relatively unmixed liquid layer surrounding the immobilized enzyme; 2. diffusion through the relatively unmixed liquid layer; and 3. diffusion from the surface of the particle to the active site of the enzyme in an inert support. By: Pn AinHarmiza 6

EFFECT OF MASS-TRANSFER RESISTANCE • Steps 1 and 2 are the external mass-transfer resistance. • Step 3 is the intraparticle mass- transfer resistance. By: Pn AinHarmiza 7

Kinetic Properties • There is usually a decrease in specific activity of an enzyme upon insolubilization: denaturation caused by the coupling process • Microenvironment after immobilization may be drastically different from that existing in free solution: the physical and chemical character of the support matrix, or interactions of the matrix with substrates or products involved in the enzymatic reaction – The Michaelis constant may decrease by more than one order of magnitude when substrate of opposite charge to the carrier matrix • The diffusion of substrate can limit the rate of the enzyme reaction: the thickness of the diffusion film determines the concentration of substrate in the vicinity of the enzyme and hence the rate of reaction • The effect of the molecular weight of the substrate can also be large. This may be an advantage in some cases, since the immobilized enzymes may be protected from attack by large inhibitor molecules

DIFFUSIONAL LIMITATIONS IN IMMOBILIZED ENZYME SYSTEMS • Diffusional resistances may be observed at different levels in immobilized enzymes. • Immobilized enzyme system normally includes: - insoluble immobilized enzyme - soluble substrate, or product • They are heterogeneous systems. By: Pn AinHarmiza 9

Substrate HIGH S b Immobilized Enzyme Low S concentration DIFFUSION DRIVING FORCE

HIGH S b Immobilized Enzyme REACTION DIFFUSION DRIVING FORCE PRODUCT

HIGH S b Immobilized Enzyme DIFFUSION DRIVING FORCE

HIGH S b Immobilized Enzyme REACTION PRODUCT

• In immobilized enzyme systems, the overall production rate is determined by: – liquid film mass transfer (external diffusion) substrate, product. – intraparticle mass transfer (internal diffusion) substrate, product in porous supports. – enzyme catalysis reaction. By: Pn AinHarmiza 14

To determine the significant effect of external diffusion resistance on the rate of enzyme catalytic reaction rate: Damköhler numbers (Da) maximum rate of reaction V ' m Da maximum rate of diffusion k [ S ] L b is the maximum reaction rate per unit of V ' m external surface area (e.g. g/cm 2 -s) k L is the liquid mass transfer coefficient (cm/s) [ b S ] Is the substrate concentration in bulk solution (g/cm 3 ) By: Pn AinHarmiza 15

maximum rate of reaction V ' m Da maximum rate of external diffusion k [ S ] L b When Da >> 1, the external diffusion rate is limiting; Da << 1, the reaction rate is limiting; Da ≈ 1, the external diffusion and reaction resistances are comparable. By: Pn AinHarmiza 16

Diffusion Effects in Surface-bound Enzymes on Nonporous Support Materials Ss Sb k 2 E+S ES P E Assume the enzyme catalyzed reaction rate follows Michaelis-Menten type kinetics. Enzyme Liquid Film Thickness, L Ss: substrate concentration at the surface; Sb: substrate concentration in bulk solution. By: Pn AinHarmiza 17

Assume: Ss Sb -Enzyme are evenly distributed on the surface of a nonporous support material. -All enzyme molecules are equally active. -Substrate diffuses through a thin liquid film surrounding the support surface to Enzyme reach the reactive surface. Liquid Film Thickness, L No intraparticle diffusion -The process of immobilization has not altered the enzyme structure and the intrinsic parameters (Vm, Km) are unaltered. By: Pn AinHarmiza 18

J The external diffusion rate (g/cm 2 -s): s J k ([ S ] [ S ]) s L b s k is the liquid mass transfer coefficient (cm/s). L If the product formation rate is : V ' [ S ] ' m s v K [ S ] m s V ' the maximum reaction rate per unit surface area. m (g/cm 2 -s) By: Pn AinHarmiza 19

k 2 E+S ES P E At steady state, the reaction rate is equal to the external diffusion rate: V ' [ S ] m s J k ([ S ] [ S ]) s L b s K [ S ] m s With the equation and known S b , K L , V m ’ or K m , to determine numerically or graphically: - The substrate concentration at the surface. - The reaction rate. By: Pn AinHarmiza 20

J k ([ S ] [ S ]) s L b s Graphical solution for reaction rate per unit of surface area for enzyme immobilized on a non-porous support By: Pn AinHarmiza 21

When the system is strongly external diffusion (liquid film mass- transfer) limited, [Ss]≈0, the overall reaction rate is equal to the rate: v k [ b S ] Da>>1 L The system behaves as pseudo first order. The rate is a linear function of bulk substrate concentration. By: Pn AinHarmiza 22

To increase the overall reaction rate with external diffusion limitation: maximum rate of reaction V ' m Da maximum rate of diffusion k [ S ] L b -Increase . -Increase . By: Pn AinHarmiza 23

The liquid film mass transfer coefficient k L: 2 / 3 1 / 2 D U AB k 0 . 6 L 1 / 6 d 1 / 2 p (H. Fogler, Elements of Chemical Reaction Engineering 1999, p705) D AB is mass diffusivity of the substrate in the liquid phase, a function of temperature and pressure (m 2 /s) ν is the kinematic viscosity (m 2 /s), a function of temperature. U is the free-system liquid velocity (velocity of the fluid flowing past the particle) (m/s). d p is the size of immobilized enzyme particle (m). At specific T and P, increasing U and decreasing d p increase the liquid film mass transfer coefficient and the external diffusion rate.

Diffusion Effects in Surface-bound Enzymes on Nonporous Support Materials When the system is strongly reaction limited, [Sb] ≈ [Ss] the overall reaction rate is equal to the rate: V ' [ S ] m b v Da << 1 K [ S ] m , app b where ' V m K K 1 m , app m k ([ S ] K ) L b m K m,app is increased. It is a function of mixing speed and S b .

Diffusion Effects in Enzymes Immobilized in a Porous Matrix - Substrate diffuses through the tortuous pathway within the porous support to reach the enzyme. - Substrate reacts with enzyme on the pore surface. Ex. Spherical support particles Sr

Diffusion Effects in Enzymes Immobilized in a Porous Matrix Assume: - Enzyme is uniformly distributed in a spherical support particle. - The reaction kinetics follows Michaelis- Menten kinetics. - There is no external diffusion limitation.

Recommend

More recommend