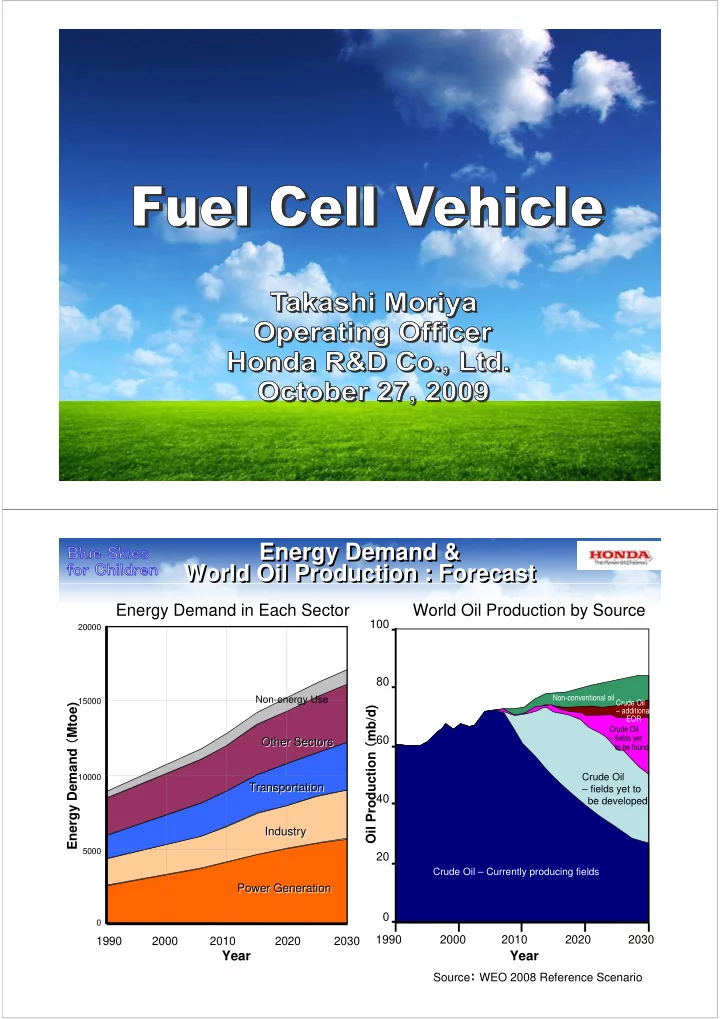

Energy Demand & Energy Demand & World Oil Production : Forecast World Oil Production : Forecast Energy Demand in Each Sector World Oil Production by Source 100 20000 80 Non-conventional oil Non-energy Use 15000 Crude Oil Energy Demand ( Mtoe) Oil Production ( mb/d) – additional EOR Crude Oil 60 – fields yet Other Sectors Other Sectors to be found Crude Oil 10000 Transportation Transportation – fields yet to 40 be developed Industry Industry 5000 20 Crude Oil – Currently producing fields Power Generation Power Generation 0 0 1990 2000 2010 2020 2030 1990 2000 2010 2020 2030 Year Year Source : WEO 2008 Reference Scenario

CO 2 Emissions Increase and CO 2 Emissions Increase and Reduction Scenarios by 2050 Reduction Scenarios by 2050 70 60 Other CO 2 Emission (Gt CO 2 ) Transport 50 Industry 40 30 1/2 Power 20 generation 10 0 Baseline Baseline Act Map Blue Map 2005 2030 2050 2050 2050 Source: ETP2008 Road Map for GHG Reduction Road Map for GHG Reduction in the Transportation Sector in the Transportation Sector 20 18 Hydrogen FCVs 16 Electrification 14 Biofuels Emissions (Gt CO 2 ) 12 Conventional & 10 Hybrid Vehicle Efficiency 8 6 12.5Gt 4 Reduction 2 CO 2 Emissions 0 2005 Base Base ACT BLUE Line Line Map Map 2030 2050 2050 2050 Source: ETP2008

Direction for GHG Reduction Direction for GHG Reduction 100 Fuel Cell Tech. Road Load Reduction Weight Reduction Vehicle Aerodynamics CO 2 reduction rate (%) Road Load Reduction EV Tech. Auxiliary Load Reduction 50 Battery Tech. Hybrid Tech. Motor Tech. Regenerating 30 Tech. Eng Tech. Diesel Variable Cylinder Tech. Gasoline Mult. AT CVT New Combustion Variable Tech. Cylinder Tech. Variable Valve Tech. 1990 2000 2010 2020 Powerplant Characteristic for Environment Powerplant Characteristic for Environment Battery EV FCV 0 H 2 Station Expansion Depend on Quick charge Depend on Quick charge (Good) or Battery replacement or Battery replacement Full Function & CO 2 Emission Plug-In Zero Emission Hybrid Vehicle Gasoline Powered Vehicle 0 100 500 1000+ (km) Driving Range

Development of Fuel Cell Vehicles Development of Fuel Cell Vehicles 1980s 1995 2000 2002 2004 2006 2008 Fundamental Fundamental FCX- FCX- V1,V2 V1,V2 V3 V3 V4 V4 research research FCX Clarity FCV (F uel C ell V ehicle ) Leasing Leasing Motor Motor EV-PLUS (Electric vehicle) EV-PLUS (Electric vehicle) technologies technologies CIVIC-GX (Natural gas vehicle) CIVIC-GX (Natural gas vehicle) Pressurized tank Pressurized tank technologies technologies Energy management Energy management Hybrid vehicle Hybrid vehicle technologies technologies INSIGHT 06 CIVIC Hybrid 06 CIVIC Hybrid INSIGHT INSIGHT INSIGHT

FCV Powerplant Components FCV Powerplant Components Coaxial Electric Drive V Flow Fuel Cell Stack Lithium-Ion High-Pressure Motor and Gearbox (Center tunnel layout) Battery Hydrogen Tank Honda FC Stack Honda FC Stack Compact, Lightweight, Higher-output Design Compact, Lightweight, Higher-output Design V Flow FC Stack Weight output density (kW/kg) 2006 Air H 2 1.5 2003 1 Coolant 0.5 1999 Wave flow channel 0 0.5 1 1.5 2 2.5 Volume output density (kW/L) Material Structural Material Structural Evolution Evolution Evolution Evolution Fluorine Aromatic Aromatic Aromatic PEM electrolytic membrane electrolytic membrane electrolytic membrane Operating 0 - 80 ℃ -20 - 95 ℃ -30 - 95 ℃ temp. Stack Bolt-fastened stack Panel box stack 1-box stack configuration Machined carbon separators Stamped metal separators Stamped metal V Flow cell structure V Flow cell structure with separate seals with unitized seals Wave flow channel separators Wave flow channel separators Cell structure

Electric drive motor Electric drive motor A more compact motor compartment for a compact, short-nose design FCX Clarity 2005 FCX Lightweight / High torque and output Continuous discharge/volt/unit weight FCX Clarity GOOD GOOD Integrated drive system structure � reduced height ▲ 240mm ▲ 240mm [kW/V/kg] 2005 FCX ▲ 162mm ▲ 162mm Coaxial layout � reduced length EV / HEV / FCV Maximum torque/unit weight Front [Nm/kg] An All-New Dimension in Driving An All-New Dimension in Driving Feel Driving performance Feel Driving performance A powerful motor for acceleration that feels limitless Going beyond the excellent off-the-line acceleration of the 2005 FCX, the FCX Clarity also adds improved acceleration in the mid- and high-speed ranges 600 120 Motor output characteristics Acceleration characteristics 3.0L Class FCX Clarity :100 kW FCX Clarity 500 100 Compact hybrid 400 80 electric vehicle 2.0~2.4L Class Passing acceleration 2005 :80 kW FCX Output [kW] Torque [Nm] 1.5~1.8L Class 300 272 Nm 60 256 Nm 2005 GOOD GOOD FCX FCV 200 40 2003 100 20 FCX 0 0 0 2500 5000 7500 10000 12500 Off-the-line acceleration Motor Speed [rpm]

FCV Commercialization: Remaining Issues FCV Commercialization: Remaining Issues Challenges, Work in Progress e.g. cost, durability, range extension, codes & standards, market acceptance, infrastructure deployment Road to FCV Commercialization Road to FCV Commercialization Preparation for Mass production Demonstration stage stage commercialization stage Cost, durability, • Cost reduction and reliability equal to gasoline- fueled vehicles Infrastructure • Improved durability and reliability Technological Progress • Extended practical range ・ Vehicle performance First FCV ・ Low temperature operation Delivery Aiming at Mass-production by progressive efforts

Study on Hydrogen Supply Study on Hydrogen Supply Solar Energy H Hydrogen 2 Manufacturing hydrogen Running a vehicle on Electrolysis of water electricity from fuel cells Creating electricity from sunlight Electrical energy Return to nature Electricity generation Water High-pressure Electrolyzer Compressor Tanks Water Nozzle Grid Summary Summary • We urgently need to develop the technology to harness new sources of energy and reduce greenhouse gas emissions. • Honda believes fuel cell vehicles are the ultimate solution to • the requirements and needs of society in the future. Our long-standing research and development work on fuel cell vehicles will continue towards a sustainable future. • While offering the exceptional environmental performance only a fuel cell-powered vehicle can, FCX Clarity does not forget the pleasure of driving. Zero CO 2 emissions and an exciting drive is what FCX Clarity is all about. • On our way toward a fully sustainable hydrogen-based society, the building of an appropriate infrastructure and achieving widespread social acceptance are essential in the popularization of fuel cell electric vehicles.

Recommend

More recommend