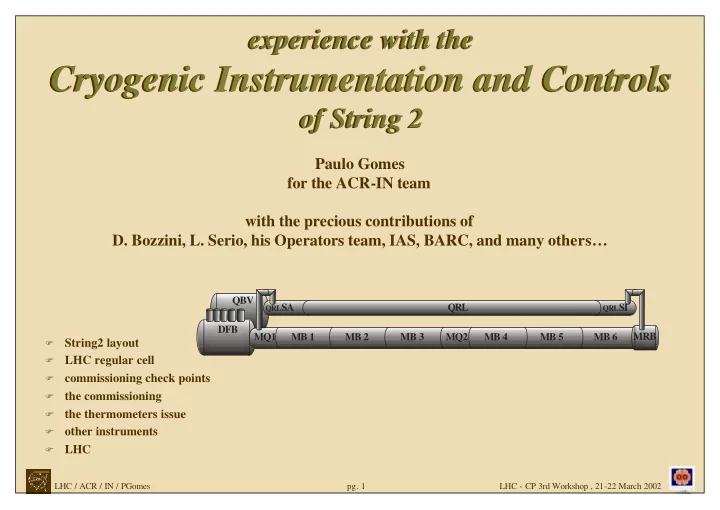

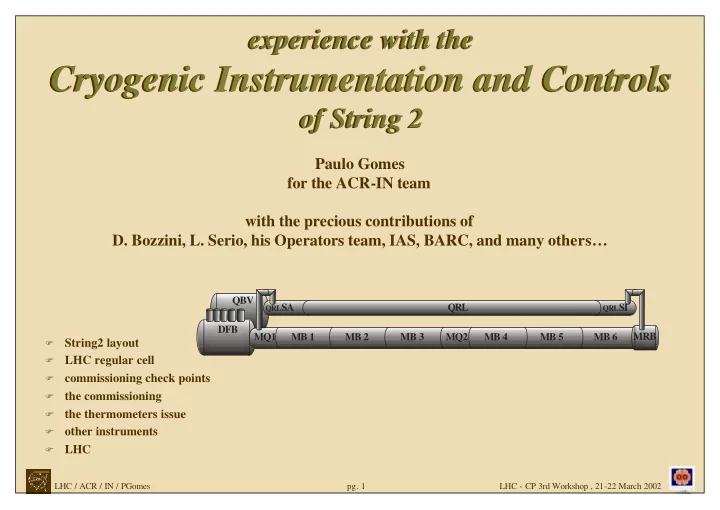

experience with the experience with the Cryogenic Instrumentation and Controls Cryogenic Instrumentation and Controls of String 2 of String 2 Paulo Gomes for the ACR-IN team with the precious contributions of D. Bozzini, L. Serio, his Operators team, IAS, BARC, and many others… QBV QRL SA QRL QRL SI DFB MRB MQ1 MB 1 MB 2 MB 3 MQ2 MB 4 MB 5 MB 6 � String2 layout � LHC regular cell � commissioning check points � the commissioning � the thermometers issue � other instruments � LHC LHC / ACR / IN / PGomes pg. 1 LHC - CP 3rd Workshop , 21-22 March 2002

on the machine distributed racks central rack control room actuators sensors signal signal remote fieldbus PLC Ethernet OWS cables conditioners I/O stations segments 80 620 300 350 40 7 Profibus 2 3 PA QLISF PA QLISR DP STRING QBV full String 2 full String 2 QRL SA QRL QRL SI DFB MRB MQ1 MB 1 MB 2 MB 3 MQ2 MB 4 MB 5 MB 6 PA DFB DP DFB PLC2 DP LHCa DP LHCb PLC1 LHC / ACR / IN / PGomes pg. 2 LHC - CP 3rd Workshop , 21-22 March 2002

intelligent instruments industrial + custom + Siemens ET200M Siemens S7-400 PCVue32 on the machine distributed racks central rack control room dumb rad-tol instruments custom ACR/IN rad-tol UNICOS - Schneider UNICOS - PVSS actuators sensors signal signal remote fieldbus PLC Ethernet OWS cables conditioners I/O stations segments 80 620 300 350 40 7 Profibus 2 3 16 23 30 18 6 2 WorldFip • one order of magnitude less instruments • more regular topology LHC regular cell LHC regular cell • custom rad-tol front-end NEED to be validated • UNICOS, Schneider, WorldFip on the String in 2003 MB 1 MB 2 MB 3 MB 4 MB 5 MB 6 DP LHCa DP LHCb LHC / ACR / IN / PGomes pg. 3 LHC - CP 3rd Workshop , 21-22 March 2002

ACR / IN on the machine distributed racks central rack control room IAS others signal conditioners OWS choice of conditioner type / range signal cables synoptic layout calibration of conditioner mapping of pin-out wire damaged PLC PLC addresses swapped sensors remote I/O stations interlocks, alarms, process Profibus addresses pin-out I/O-mem mapping addresses Profibus address communication with ABB I/O module type logic of interlocks, alarms, process pin-out sensors sensor calibration functions correspondence SN --Tag choice of sensor type / range commissioning commissioning mathematical function integrity wrong info on TT type (CX, Pt100, CRT) correspondence SN --Tag swapped SN checkpoints checkpoints unknown SN unreported change of SN late info on SN Ethernet mechanical mounting wire/ block thermalisation IP addresses, routers Profibus networks electrical mounting electromagnetic noise bus terminations sensor / wire damaged contacts inside connectors pin-out LHC / ACR / IN / PGomes pg. 4 LHC - CP 3rd Workshop , 21-22 March 2002

the commissioning the commissioning 1. Ethernet 2 PLC / EWS / OWS 2. Profibus all remote I/O stations accessible (cable continuity, Profibus address) all I/O modules well configured, in each station 3. databases PLC & OWS synchronised (by forcing values on PLC) all parameters & values for sensors / actuators all parameters & thresholds for interlocks / alarms / process 4. once SPV application on the OWS is reliable, qualitative inspection of sensor values (@ room T, P) � identification of completely wrong values wrong pinout / broken sensor, wire, conditioner CX / Pt100 identification error wrong range settings � instrumentation commissioning needs PLC / OWS / ethernet running NEED access to LAN in LHC tunnel 5. first set of simple/obvious corrections 6. quantitative/fine inspection of values (@ nominal T, P, dT_gradients) swapped, inaccurate, non-identified sensors 7. if problem follow signal chain (hardware + software) connector on machine / connector on rack / connector on I/O module PLC physical value / PLC engineering value / OWS database LHC / ACR / IN / PGomes pg. 5 LHC - CP 3rd Workshop , 21-22 March 2002

the thermometers issue - identification the thermometers issue - identification (440 TT) TT with SAME transfer function 300 Pt100 TT with INDIVIDUAL transfer function 140 Cernox each and every Cernox must be : UNAMBIGUOUSLY identified IN TIME for producing the corresponding PLC interpolation table enormous effort to get IDs from the responsibles of every system not always correct at the first iteration !!! NEED much more DISCIPLINE from the TT users LHC / ACR / IN / PGomes pg. 6 LHC - CP 3rd Workshop , 21-22 March 2002

the thermometers issue - installation the thermometers issue - installation cooper wires instead of manganin wires wires not protected against sharp edge the specs were not respected (materials, mounting, wiring) SOME have been repaired point welding of support dangling and stretched wires others … nobody has a clue on how they are mounted !!! MUST users take photos of every TT ? LHC / ACR / IN / PGomes pg. 7 LHC - CP 3rd Workshop , 21-22 March 2002

the thermometers issue - Current Leads (200 TT) the thermometers issue - Current Leads all 38 CL numbered in reverse order bad documentation 100% in every CL circular permutation of the 6 TT TT type some changed from CX to Pt100 quality assurance ? >10 TT lost >10% >10 TT broken wires LHC / ACR / IN / PGomes pg. 8 LHC - CP 3rd Workshop , 21-22 March 2002

the thermometers issue - accuracy the thermometers issue - accuracy (28 TT) 10 000. 1.798 1.798 1.790 1.869 1.898 1.8 PLC 1 000. 1.9 PLC 100. DT [mK] 10. 5mK <-> 0.25% in the MAGNETS @ nominal T=1.8K, expected accuracy 1. is better than 10mK all errors understood, 0.1 1 2 4 1 2 1 2 1 2 1 1 1 2 1 2 1 1 1 2 1 2 1 1 1 2 4 1 2 1 1 1 2 2 4 4 6 6 4 6 4 4 6 6 4 6 4 4 6 6 4 6 1 1 1 2 2 2 2 2 2 2 3 3 3 3 4 4 3 3 3 3 4 4 3 3 3 3 4 4 2 2 2 2 2 thermometers calibs OK T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T T _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ T T T T T 1 1 1 1 1 1 2 2 2 2 2 2 3 3 3 3 3 3 G G G G G A A A A A B B B B B B B B B B B B B B B B B B A A A A A O O O O O M M M M M M M M M M M M M M M M M M O O O O O no re-calibration needed ! Q Q Q Q Q . Q Q Q Q Q L L L L L L L L L L SSS3 MBP201 MB2PA2 MBP2N1.V3 SSS4 LHC / ACR / IN / PGomes pg. 9 LHC - CP 3rd Workshop , 21-22 March 2002

the thermometers issue - magnets (28 TT) the thermometers issue - magnets MQ1 / SSS3 : 1/3 1 TTcm bad calib of unknown origin 100 mK 1 TTvac not perfect mounting 30 mK 2/2 MQ2 / SSS4 : 1 TTvac Cu wires + 10cm inox 1 000 mK � 2 TTcm swapped 2/3 1 TT to gnd ~ 1 TTvac not perfect mounting 30 mK 2/2 1 TTvac 10cm inox 300 mK MB1 / MBP2O1 : 3 TT broken wires ~ 2 TTcm lost on the Bench X 2 TT reversed wires ~ 2/2 � 1 TTcm replaced 1 TT grounded wires ~ 1 TTvac broken wires ~ 1/4 MB2 / MBP2A2 : MB4 / A001_2 : 2/4 2 TTvac not perfect mounting 40 mK 100% 1 TTcm damaged ~ MB3 / MBP2A1s : 2/2 2 TTcm damaged on the Bench ~ 1 TTvac not perfect mounting 50 mK 1/4 1 TT broken wires ~ 1 TT reversed wires ~ LHC / ACR / IN / PGomes pg. 10 LHC - CP 3rd Workshop , 21-22 March 2002

the thermometers issue - let’s be serious! the thermometers issue - let’s be serious! too many broken / grounded wires most of them repaired (but degraded accuracy) swapped sensors / wires re-installed sensors risk of damage lost sensors (during Bench tests ?) too long time to identify repair � ACR/IN should not supply TT without knowing their exact destination � users must strictly follow installation guide � users should produce accurate documentation on location, pin-out, follow-up � users should check integrity at all phases of assembly (traveler doc) � ACR/IN has no resources to inspect all systems before closure ! � should users take photos of every TT ? high risk of blindness for LHC !! otherwise ( series magnets have only 1 TT ) LHC / ACR / IN / PGomes pg. 11 LHC - CP 3rd Workshop , 21-22 March 2002

other instruments other instruments 1 PT lost in MB1 / MBP2O1 not LHC 3 LT (LHe wetting indicators) grounded wires 1 EH lost in MB1 / MBP2O1 lost firmware config � card replacement 3/10 intelligent valve positioners LHC / ACR / IN / PGomes pg. 12 LHC - CP 3rd Workshop , 21-22 March 2002

commissioning summary commissioning summary many unexpected problems 3 months to commission only the cooldown related instruments Operator and Engineering WS next to the plant NEED access to LAN in LHC tunnel 2 more months commissioning instruments & control for nominal conditions ( T, P, I ) 2.5 more months still hunting for bad TT (not yet finished !) commissioning time MUST not be neglected !! the positive note: we managed to always be on time for the milestones (also thanks to mechanical assembly delays …) LHC / ACR / IN / PGomes pg. 13 LHC - CP 3rd Workshop , 21-22 March 2002

Recommend

More recommend