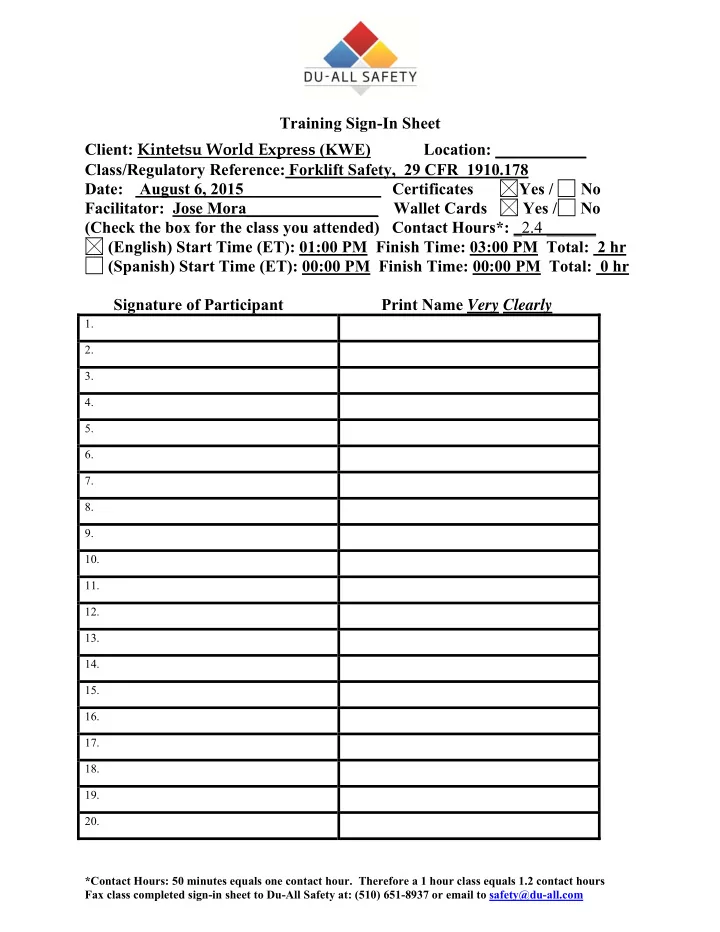

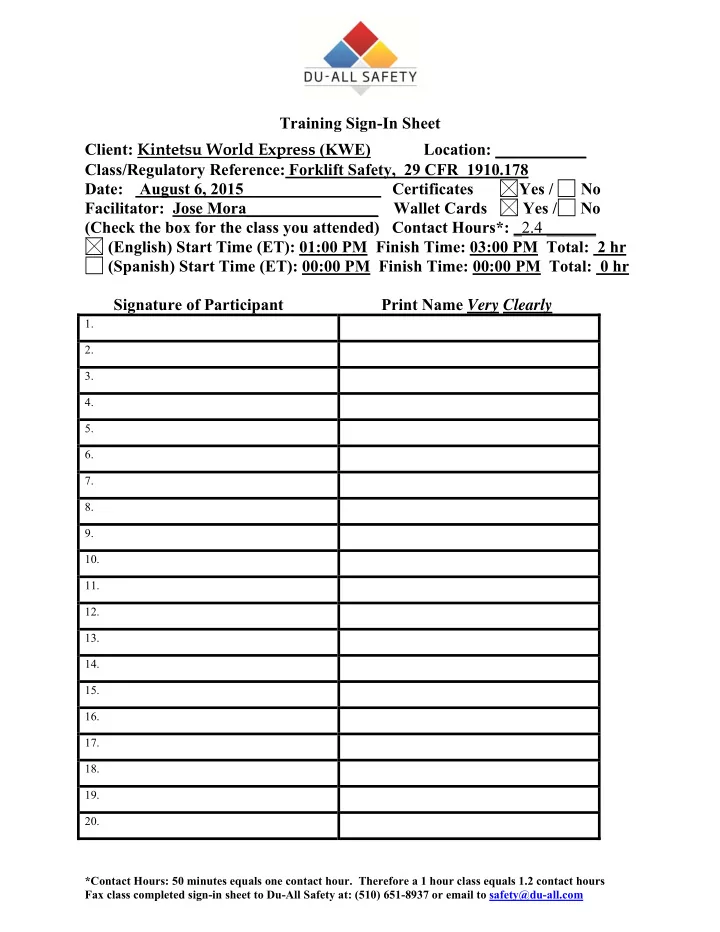

Training Sign-In Sheet Client: Kintetsu World Express (KWE) Location: ___________ Class/Regulatory Reference: Forklift Safety, 29 CFR 1910.178 Date: August 6 , 2015 Certificates Yes / No Facilitator: Jose Mora________________ Wallet Cards Yes / No (Check the box for the class you attended) Contact Hours*: _2.4 ______ (English) Start Time (ET): 01:00 PM Finish Time: 03:00 PM Total: 2 hr (Spanish) Start Time (ET): 00:00 PM Finish Time: 00:00 PM Total: 0 hr Signature of Participant Print Name Very Clearly 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. *Contact Hours: 50 minutes equals one contact hour. Therefore a 1 hour class equals 1.2 contact hours Fax class completed sign-in sheet to Du-All Safety at: (510) 651-8937 or email to safety@du-all.com

Powered Industrial Truck Objectives Operator Training - Initial In this course, we will discuss the following: Operator training and evaluation Minimum OSHA general requirements for powered industrial trucks (PITS) ( ) Safe operation of equipment Hazard identification Abatement methods and Presented by : Jose M Mora, Du-All Safety procedures Date : 2015 Operator Training Operator Training Employer shall ensure each powered industrial Trainees may only operate the truck: truck operator is competent to operate a Under direct supervision of trainer powered industrial truck safely Where such operation does not endanger the trainee or other As demonstrated by successful completion of employees training and evaluation. Operator Training Operator Training 1910.178(l)(3) Training program content – initial training Training program must consist of a combination of: Truck-related topics Formal instruction, for example » Lecture » Discussion Workplace-related topics » Interactive computer learning » Video, written material Practical training exercises Practical training exercises Regulatory requirements Regulatory requirements Evaluation Operator training and evaluation Shall be conducted by a person who have the knowledge, training, and experience 1

Operator Training Operator Training Fork and attachment adaptation, operation, use Truck-related topics Differences from automobile Vehicle capacity and stability Operating instructions, warnings and precautions Vehicle inspection and maintenance that the operator will be required to perform Controls and instrumentation Co o s a d s u e a o Refueling/charging/recharging batteries Engine or motor operation Operating limitations Steering and maneuvering Other instructions, etc. Visibility Operator Training Operator Training Operating in hazardous (classified) locations Workplace-related topics Surface conditions Operating on ramps and sloped surfaces Composition and stability of loads Potentially hazardous environmental conditions Load manipulation, stacking, L d i l ti t ki Operating in closed environments or other areas unstacking where poor ventilation or maintenance could cause carbon monoxide or diesel Pedestrian traffic exhaust buildup Narrow aisles and restricted areas Operator Training Operator Training Refresher training and evaluation Employer must certify that each operator has Operator observed operating vehicle in unsafe been trained and evaluated manner Certification must include: Involved in accident or near-miss incident Name of operator Name of operator Evaluation reveals not operating truck safely Date of training Assigned to different type of truck Date of evaluation Conditions in workplace change Identity of trainer 2

General Requirements General Requirements Both Cal-OSHA and Fed-OSHA have This standard covers safety requirements regulations regarding the operations of relating to fire protection, design, maintenance, industrial trucks. and use of: Fork trucks Cal OSHA Title 8- General Safety Orders, Sections Tractors Tractors (Effective July 15 2000) (Effective July 15, 2000). »3650 – Industrial Trucks. General. Platform lift trucks »3664 – Operating Rules. Motorized hand trucks »3668 – Powered Industrial Truck Operator Training. Other specialized industrial trucks Fed OSHA Title 29- Code of Federal Regulations, Section (Final) ….powered by electric motors or internal »1910.178 - Powered Industrial Truck Operator Training. combustion engines. Safe Operating Rules General Requirements Class I - Electric Motor Rider Trucks Class I - Electric Motor Rider Trucks General Requirements Counterbalanced rider Class II - Electric Motor Narrow Aisle Trucks type, stand up. Three wheel electric trucks, sit-down. Counterbalanced rider type cushion tires sit type, cushion tires, sit- down (high and low platform). Counterbalanced rider, pneumatic tire, sit-down (high and low platform. Risk - tip over 3

Class II - Electric Motor Narrow Aisle General Requirements Trucks Class III - Electric Motor Hand Trucks or High lift straddle Hand/Rider Trucks Order picker Reach type outrigger Side loaders, turret trucks, swing mast and convertible turret/stock pickers pickers Low lift pallet and platform (rider) Designed to operate in narrow passageways; have a narrow track that prevents their safe operation on rough surfaces. Risk – tip over, fall, and crush hazards Class III - Electric Motor Hand or General Requirements Hand/Rider Trucks Class IV - Internal Combustion Engine Low lift platform Trucks (Solid/Cushion Tires) Low lift walkie pallet Reach type outrigger High lift straddle High lift counterbalanced g Low lift walkie/rider pallet Risk – Accidental damage to property, crush/struck by injuries, load stability Class IV - Internal Combustion Engine General Requirements Trucks - Cushion (Solid) Tires Class V - Internal Combustion Engine Trucks (Pneumatic Tires) Counterbalanced Sit-down Cushion (solid) tire Cushion (solid) tire Risk - tip over 4

Class V - Internal Combustion Engine General Requirements Trucks (Pneumatic Tires) Class VI - Electric and Internal Combustion Engine Tractors Counterbalanced Sit-down Pneumatic tire Pneumatic tire Risk - tip over Class VI - Electric & Internal Combustion General Requirements Engine Tractors Class VII - Rough Terrain Forklift Trucks Sit-down rider Rough Terrain Extended-Reach Rough Terrain Straight Mast Forklifts Forklifts 5

Common Misconceptions Common Causes of Forklift Accidents Federal OSHA research has identified 1. Forklifts can’t go very fast and therefore are the most common causes of forklift not very dangerous. True or False? accidents. 2. Driving a forklift is basically no different from Vehicle Tip-Over driving a car. True or False? Person Struck by Truck Person Struck by Falling Load 3. All forklifts are basically the same. True or y Elevated Employee on the Truck False? Running off a Loading Dock or Other Surfaces Improper Maintenance Lost Control of Truck Material Struck by Truck Review FACE Reports General Requirements General Requirements Does not apply to: All new PITs acquired and used by an employer shall meet the design requirements of: Compressed air or nonflammable compressed American National Standard for Powered Industrial Trucks, Part II, ANSI B56.1– 1969’’, which is incorporated by reference gas-operated industrial trucks as specified in § 1910.6 Farm vehicles Approved trucks shall bear a label or some other Vehicles intended primarily for identifying mark indicating approval by the testing earth moving or over-the-road laboratory. hauling. OSHA letter of interpretation dated 03/07/2000 General Requirements General Requirements Truck equipped with front-end attachments other than Modifications and additions which affect capacity and factory installed: safe operation must have prior written approval from manufacturer. Marked to identify the attachments Show approximate weight of truck and attachment 6

Recommend

More recommend