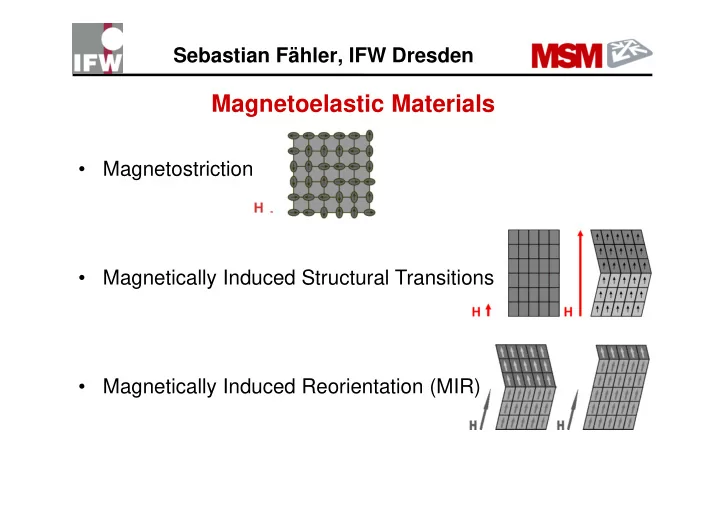

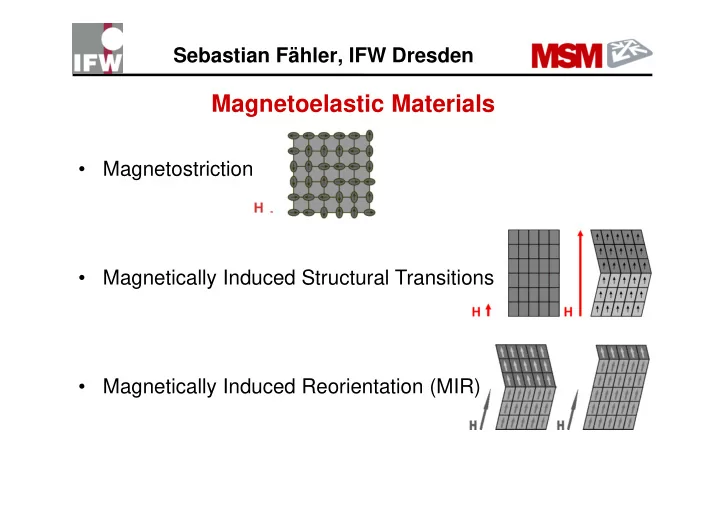

Sebastian Fähler, IFW Dresden Magnetoelastic Materials • Magnetostriction • Magnetically Induced Structural Transitions • Magnetically Induced Reorientation (MIR)

Magnetostrictive effects Anisotropic magnetostriction Spontaneous magnetostriction Volume magnetostriction Ni R. C. O’Handley, Modern Magnetic Materials (2000) 2

Anisotropic magnetostriction In first order, volume is conserved Saturation magnetostriction λ S when all moments are aligned R. C. O’Handley, Modern Magnetic Materials (2000) 3

Origin of magnetostriction Below T C : Spin-Orbit coupling alligns orbits Modifies distance between atoms (spontaneous magnetostriction) Magnetic field modifies direction (anisotropic magnetostriction) B. D. Cullity, Introduction to Magnetic Materials (1972)

Magnetostriction and domains [010] [100] ∆ l l H H H H l −∆ l � Ideal case: Demagnetized state consists of all possible domains in equal fraction λ S > 0: Extension in field direction λ S < 0: Compression in field direction 5

Magnetostriction of a Fe single crystal , easy axis λ = + -6 20.5x10 100 λ = − , hard axis -6 21.5x10 111 � Complex behavior when domain wall motion and rotation is involved B. D. Cullity, Introduction to Magnetic Materials (1972) 6

Inverse magnetostriction Straining of a 500 nm FeCoBSi film � Stress induced anisotropy � Easy axis aligns along strain direction S. Glasmachers, M. Frommberger, J. McCord, E. Quandt, phys. stat. sol. (a) 201, 3319 (2004) 7

Applications of magnetostriction Applications: Ni � Ultrasonic sound generators � Microactuators + sensors Best for applications: � Low hysteresis � Bias field Best materials: Symmetric curve � Terfenol-D (Dy,Tb)Fe 2 : 0.24% -> Frequency doubled � Galfenol (Fe-Ga): 0.03 % 8

Anisotropic magnetostriction - Strain < 0.24 % + High frequency � Single ion anisotropy + Low magnetic field O. Heczko, J. Mag. Mag. Mat. 290-291 (2005) 846 9

Martensitic transformation T > T M : Austenite (high symmetry) T < T M : Martensite (low symmetry) � No diffusion, reversible + Strain > 5% � Twinned microstructure + High forces - Low frequency 10

Stress – Strain - Temperature Martensite Martensite M F M S A S Martensite A F Austenite � Different trajectories can be used in shape memory materials – Pseudoelasticity – Pseudoplasticity – Shape memory effect 11

Martensitic transformation of magnets Ni 2.15 Mn 0.81 Fe 0.04 Ga A. N. Vasil'ev, V. D. Martensite or Buchel'nikov, T. Austenite Takagi, V. V. Khovailok, E. I. Ferromagnetic Estrin, Physics Uspekhi 46(6) Martensite (2003) 559-588 ~ 1 K/T Non magnetic Austenite � Modification of structure and - High magnetic field >> 1 T shape by a magnetic field - Narrow temperature regime 12

Magnetically Induced Martensite (MIM) Magnetic field favors ferromagnetic phase Clausius Clapeyron: ∆ dT J = − ∆ dH S � Magnetic actuation + Remote actuation � First order structural transition � Latent heat 13

Electronic origin of martensitic transformation M. Gruner A3: P. Entel, Ni 2 MnGa U. Duisburg-Essen Martensite Austenite � Austenite and Martensite are ferromagnetic � Martensitic deformation allows to reduce energetically unfavorable high DOS at E F P. Entel et al. J. Phys. D: Appl. Phys. 39 (2006) 865 14

Metamagnetic martensite Ni 45 Co 5 Mn 36.7 In 13.3 Ferromagnetic Austenite Nonmagnetic Martensite M S A F 2 /kg) 4T 8T 100 magnetization M (Am 1T 50 M F A S 0 0 100 200 300 400 temperature T (K) � Collapse of magnetisation by martensitic transition � External field shifts martensitic transformation to lower temperatures A.N. Vasiliev, O. Heczko, O.S. Volkova, T.N. Vasilchikova, T.N. Voloshok, K.V. Klimov, W. Ito, R. 15 Kainuma, K. Ishida, K. Oikawa, and S. Fähler, J. Phys. D: Appl. Phys. 43 (2010) 055004

Magnetically Induced Austenite (MIA) Magnetic field favors ferromagnetic phase Clausius Clapeyron: ∆ dT J = − ∆ dH S Negative ∆ J → H stabilizes austenite Larger ∆ J by metamagnetic transition (not close to T C ) → Lower magnetic field required 16

Magnetically Induced Austenite (MIA) Ni 45 Co 5 Mn 36.7 In 13.3 High J Austenite R. Kainuma et al. Nature 439 (2006) 957 Low J Martensite + Strain ~ 3% � Hysteresis may inhibit Hysteresis losses? reversibility + No anisotropy needed 17

Energy Balance for MIA 120 250 K 265 K 2 /kg) 100 297 K A.N. Vasiliev, O. Heczko, magnetization (Am 80 O.S. Volkova, T.N. 350 K Vasilchikova, T.N. Voloshok, K.V. Klimov, 60 W. Ito, R. Kainuma, K. 400 K Ishida, K. Oikawa, and S. 40 Fähler, J. Phys. D: Appl. Phys. 43 (2010) 055004 20 4 K 150 K 0 0 2 4 6 8 10 external magnetic field µ 0 H (T) H ∫ ∆ � Energy input: (hatched area) S JdH 0 � Can be increased by inceasing H � But: In this case no external work was performed, hence Energy input = Hysteresis loss 18

Rubber-like behavior Ni-Mn-Ga K. Rolfs, A. Mecklenburg B2: R. Schneider 5M At const T < T M F � Easy movement of twin boundaries - Little pinning of twin (~ MPa) boundaries at defects K. Rolfs, A. Mecklenburg, J.-M. Guldbakke, R.C. Wimpory, A. Raatz, J. Hesselbach, R. Schneider, 19 JMMM 321 (2009) 1063

Twin boundary movement NM Ni-Mn-Ga M. Gruner A3: P. Entel, U. Duisburg-Essen Twin Twin boundary boundary � Only small movements of atoms required � But a collective movement would require to move 10 23 atoms simultaneously... 20 M. E. Gruner, P. Entel, I. Opahle, M. Richter, J. Mat. Sci. 43 (2008) 3825

Excursion: Dislocations � How to deform a crystals by external stress? H. Föll/ U. Kiel http://www.tf.uni-kiel.de/ matwis/amat/def_en/index.html � Dislocations allows to move line defect instead of a complete plane 21

Magnetically Induced Reorientation (MIR) Twin boundary movement No phase transition, affects only microstructure Requires: ++ Strain up to 12 % � Non-cubic phase + High frequency � High magnetocrystalline aniosotropy � Easily movable twin boundary 22

Ferromagnet � Rotation of magnetization must be avoided - High H A ⇒ high magnetocrystalline - Switching field H S < H A anisotropy needed 23

Domain pattern during MIR 5M Ni-Mn-Ga Y. W. Lai B1: J. McCord, R. Schäfer IFW Dresden H 0 mT 145 mT 146 mT 172 mT 195 mT 330 mT � Magnetic field moves twin boundary instead of rotating magnetization Y. W. Lai, N. Scheerbaum, D. Hinz, O. Gutfleisch, R. Schäfer, L. Schultz, J. McCord, App. Phys. Lett. 90 (2007) 192504

Integral measurement of strain and magnetization Ni-Mn-Ga 4 5 3 5M H H 3 4 2 2 1 5 O. Heczko, L. Straka, N. Lanska, K. Ullakko, J. 3 4 5 1 Enkovaara, J. Appl. Phys. 91 (10) (2002) 8228 o moderate switching 2 1 field H S < 1 T 25

Magnetically Induced Reorientation 5M Ni-Mn-Ga Y. W. Lai B1: J. McCord, R. Schäfer IFW Dresden } 6…10 % strain F F Restoring force by spring

Actuation under load Ni-Mn-Ga 5M 2 H 1.1 MPa 3 Blocking stress ~2 MPa F 1 - low blocking stress S. J. Murray, M. Marioni, S. M. Allen, R. C. O'Handley, T. A. Lograsso, Appl. Phys. Lett. - low forces 77(6) (2000) 886 27

Energy balance Gain of magnetic energy density by reorientation ≅ J 1 easy axis = w k H J U A S J max 2 S = σε w Mechanical work density 0 hard axis σ Maximum internal and external stress : c H H ε = − ≈ Maximum strain : 1 6 ... 10 % A a 0 Balance σε = k U 0 - low blocking stress - low forces k ⇒ σ = ≈ U 2 MPa + high work output ε 0 28

Comparison with other smart materials www.intellimat.com � Strain up to 10% � High frequency possible Refers only to the material, not to the complete system! � High specific work output � Low forces ~ MPa � Switching fields 0.1 - 1 T 29

Beneficial conditions for MIR Intrinsic properties (composition, phase) High martensitic transformation temperature ⇒ high application • temperature High magnetocrystalline anisotropy ⇒ avoids rotation of • magnetization High magnetization ⇒ efficient coupling to external field • c ε = 1 − • Maximum strain a 0 Extrinsic properties (microstructure, texture) ε < ε • High strain 0 • Low switching field H S < H A Easily moveable twin boundaries ⇒ rubber like behavior • Aim: high strain in low magnetic fields 30

Magnetic Shape Memory Alloys Magnetically Induced Magnetically Induced Martensite/Austenite (MIM/MIA) Reorientation (MIR) + Little constrains on microstructure - Rubber like behavior needed + No magnetocrystalline anisotropy - High magnetocrystalline needed anisotropy Work input increases with H - Low forces - High fields > 1 T + Moderate fields < 1 T - Works only at the vicinity of + Works below martensitic martensitic transformation transformation - Magnetocaloric effect inhibits high + High frequency (kHz) possible frequency 31

A hierarchical “twin within twins“ microstructure A. L. Roytburd, Phase Transitions 45 (1993) 1 FIB AFM SEM � Epitaxial Ni-Mn-Ga films 2 m 2 nm 200 m µ µ Mesoscopic TB S. Kaufmann, R. Niemann, T. Thersleff, U. K. Rößler, O. Heczko, J. Buschbeck, B. Holzapfel, L. Schultz and S. Fähler, 32 New J. of Physics 13 (2011) 053029

Recommend

More recommend