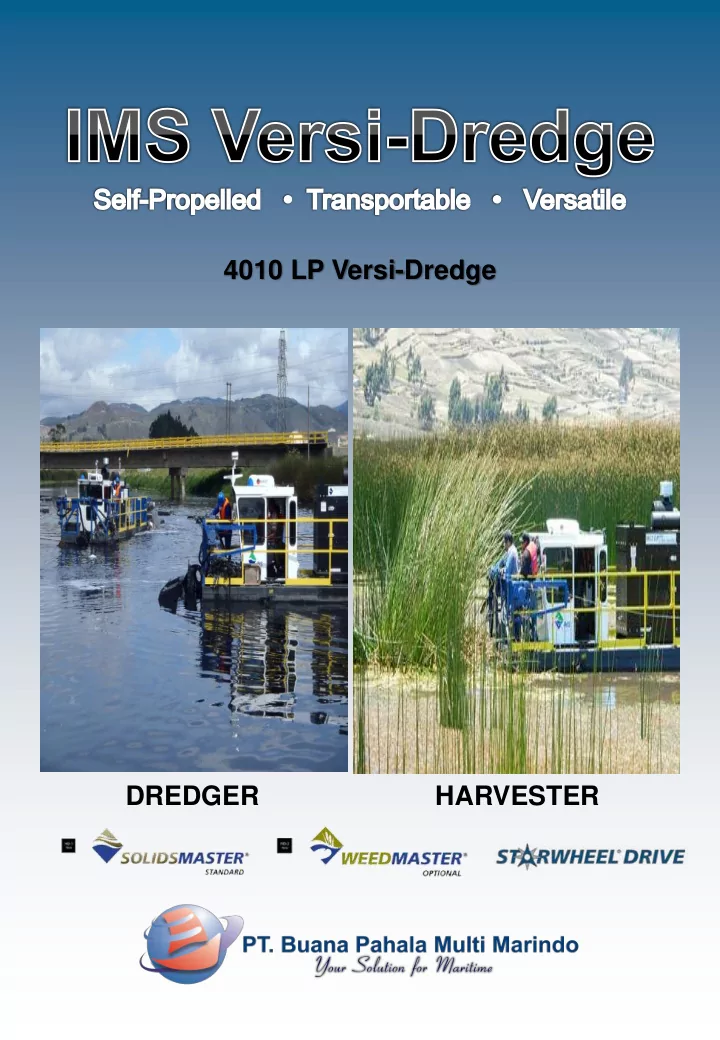

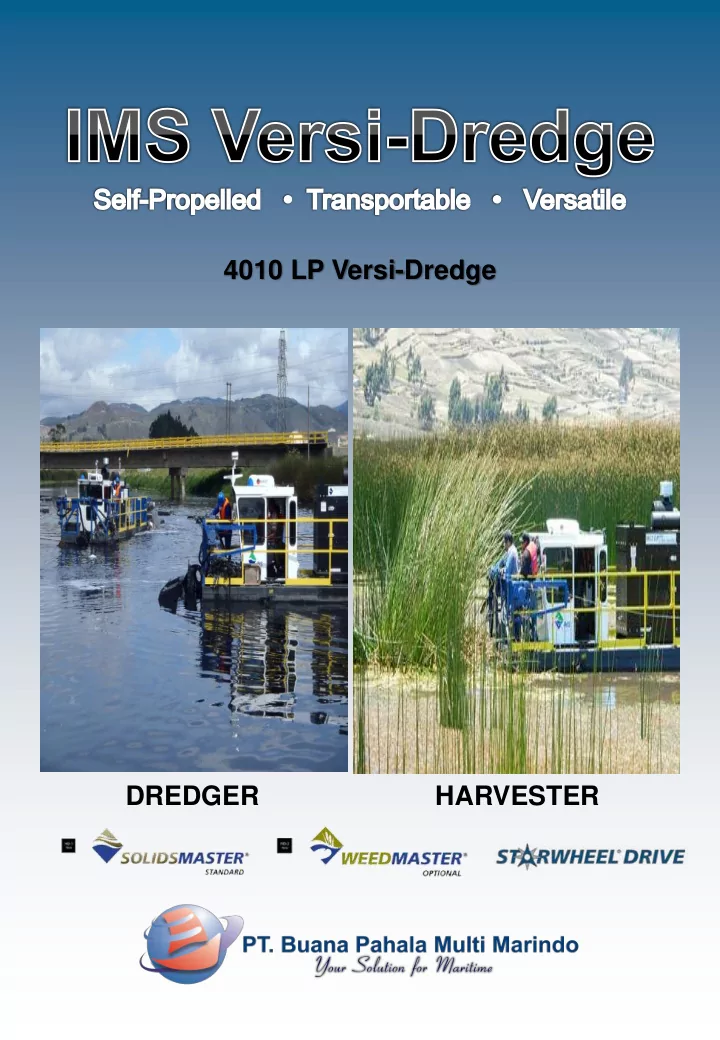

4010 LP Versi-Dredge DREDGER HARVESTER

About IMS IMS factory is largest dredge manufacturing facility in the Americas. Approximately 200 employees. 40 minutes away from international airport. Multi-million dollar parts inventory. 1986 – Founded by Jim Horton in Olathe, KS. 1989 – IMS exports its first dredge to SE Asia. 1996 – IMS patents the the Starwheel Drive self- propulsion system. 2000 – Awarded Kansas State Governor’s Exporter of the Year Award. 2003 – IMS bought by Ellicott, a 125 year old dredge builder that supplied the dredges for the Panama Canal. 2009 – IMS and its affiliates are purchased by Markel Ventures, a subsidiary of Markel MKL (NYSE), an organization valued at close to $8 billion USD. 2014 – IMS Awarded the U.S. President’s E-Award by U.S. Commerce Secretary Penny Pritzker. 2015 – IMS gets patent awarded for Razor Tooth WeedMaster Cutterhead which is only system in the world proven to cut and pump aquatic vegetation. 1

Training & Support IMS provides extensive on site training during the launch of each dredge system. IMS is committed to never turning their back on the customer and that is why most of our customers are repeat buyers. IMS provides unlimited technical support via phone and e-mail for the operating life of the equipment. Emergency visits and warranty visits can be easily arranged . IMS is working to place a regional field service and warranty technician in Indonesia by 2016. The technician would take service calls and handle all warranty work locally. IMS is the only dredge builder in the world with a horizontal cutterhead dredge simulator for pre-start-up training. Available exclusively at the factory for all IMS customers. System has 3 flat screens and a moving base that provides real life motion to make operator feel like they are on an actual dredge. Allows new operators to get chair time before starting on a new dredge in the field. 2

System Overview Self-Propelled w/ patented Starwheel Drive 10” (254mm) rubber lined dredge pump. 8’ (2.4 meter) wide low – turbidity Excavator cutterhead/. 8 ’ (2.4 meter) interchangeable Weedmaster cutterhead . Joystick controls 275 HP Diesel / Hyd. Power Unit. 20’ (6 meters) digging depth standard. Sediment Dredging Pump : Ladder mounted IMS 10 ” (254mm) discharge pump with 6 ” (152mm) spherical solids capability. Discharge Line : 10 ” (254mm) Depth : Dredges to 6.0m with self-propulsion and 6.7m with cable drive Production : 680 m3/hr mixture at 20-30% max solids Materials : silt, sand, sedimentary clay, and light plastics and trash. 3

Vegetation Dredging Pump : Ladder mounted IMS 10 ” (254mm) discharge pump with 6 ” (152mm) spherical solids capability. Discharge Line : 10 ” (254mm) Depth : Dredges to 6.0m with self-propulsion and 6.7m with cable drive. Production : – Hyacinths: clears 170+m2 / hr. – Cattails: clears 40-80m2 / hr. Materials : hyacinths, hydrilla, cattails, reeds and other rooted, floating, and submerged aquatic vegetation species. Patented Self-Propulsion STARWHEEL DRIVE Most effective dredge propulsion system available on the market today. Patent is held exclusively by IMS. No cables, no anchors, no hassle. Will not interrupt boat traffic. Increases efficiency by up to 40%. Reduces operating cost since no tender boats or barges required. Paddle Wheel Mode: paddles dredge into position and also works well in sludgy applications. Bottom Traction Mode: walks dredge forward on bottom surface with positive traction and stability. Won’t clog up like propellers. 4

Patented Self-Propulsion STARWHEEL DRIVE Most effective dredge propulsion system available on the market today. Patent is held exclusively by IMS. No cables, no anchors, no hassle. Will not interrupt boat traffic. Increases efficiency by up to 40%. Reduces operating cost since no tender boats or barges required. Paddle Wheel Mode: paddles dredge into position and also works well in sludgy applications. Bottom Traction Mode: walks dredge forward on bottom surface with positive traction and stability. Won’t clog up like propellers. 5

Transportability & Launching Easy to Launch Ocean Transport Land Transport Launch with single One truck transportable Can ship on flat rack if crane service is available. 4 lifting points on Starwheels off and deck that double as shipped with 300’ (91m)of mooring cleats. flexible discharge hose and floats in an ocean container. Operator’s Station Dual joystick controls manage all major dredge functions. Ergonomic air ride, adjustable chair. Trouble shooting operator interface with error coding for easy trouble shooting. Climate controlled, acoustic lined cab. Dual folding doors for exit on both port and starboard decks. Horn, 360 degree external lighting, fan, and internal lights. Oversized analog gauges for quick glance hydraulic pressure readings. Digital depth gauge. 6

Pipeline Discharge Configuration Allows dredge to move material 600m away from dredging site depending on material weight. Eliminates the need to re-handle material. Booster pumps can be added for longer pumping distances. Broadcaster Discharge Configuration Optional IMS Bi-Directional Broadcaster connects to end of discharge ladder replacing standard discharge line configuration. Projects high volume of solids in a large arc to the shore of the canal or river. Water filters off and solids settle on shore. Environmentally friendly. 7

Versi-Dredge Hydraulic Dredging 8

Hydraulic Dredging: Canal Maintenance Iraq Canals A private Iraqi contractor purchased a to rehabilitate a canal system in Iraq. The Versi-Dredge was chosen for its reliable reputation, high production, and self- propulsion system. Over 12 IMS units were shipped to Iraq for rehabilitation of irrigation canals and the Tigris and Euphrates. Panama A contractor selected the Versi-Dredge over several other dredge brands and dredging methods. The Starwheel Drive self-propulsion and horizontal cutterhead allowed the contractor to deepen the canal and maintain an even bottom profile without having to deal with anchor cables or swing wires. No other one truck transportable dredge can out perform the Versi-Dredge in inland canals. 9

Hydraulic Dredging: Environmental Burnaby Lake Two IMS Model Versi-Dredges restored Burnaby Lake in Vancouver, Canada. Versi-Dredge chose for its versatility and environmental friendly cutter design. Used IMS’s optional GPS accessory for recording progress against a pre-dredging survey. Endangered turtles were present in lake. Low turbidity of cutterhead was key to allowing the contractor to proceed with project. Project won multiple environmental awards. Hydraulic Dredging: Port Maintenance Port Umm Qasr, Iraq A Versi-Dredge cleaning out patrol boat lifts at Port Umm Qasr located at mouth of river. River is silting up boat lifts. Patrol boat slips and lift area cleared by Versi-Dredge. Allowed Iraqi patrol vessels to perform critical missions. Unit selected by US Dept. of Defense, The Naval Transition Team (NATT) and Royal British Navy. 10

Hydraulic Dredging: Harbor Maintenance North Wales A Versi-Dredge performs maintenance dredging at Deganwy Marina in North Wales. Unit was able to maneuver in marina without disturbing boat traffic or moving docks. The dredge was featured on the BBC. 11

Versi-Dredge Hydraulic Weed Harvesting 12

Hydraulic Weed Harvesting: Weedmaster Overview Cutting Technology Converts dredger into weed harvesting system. IMS holds exclusive patent on WeedMaster technology which allows dredge to cut and pump vegegation. No need for unloading barges or re-handling previously cut vegetation. Dredge cuts and pumps the material over several hundred meters away to a disposal area or broadcasts it on the side of canals for wetland restoration. The WeedMaster can handle floating vegetation, rooted vegetation (below water line), and submerged vegetation. Competitive Advantages YELLOW = Superior Capability & Performance 13

Hydraulic Weed Harvesting: Irrigation Canal Cleaning Angola Irrigation Canals Weedmaster Cutterhead attachment used to remove 25 km of dense vegetation from agriculture irrigation canals. Results: Dramatic water flow increase. Roads that have been flooded for decades are now dry. Government purchased a unit after contractor proved the Versi-Dredge worked. Hydraulic Weed Harvesting: Hyacinths Removal Ecuador IMS won global tender to supply hydraulic dredger / weed harvester for cleaning Laguna de Colta in Ecuador which is over 2km above sea level. Ecuador’s Minister of Environment launched the system in late 2012. The system cut 10 ft. (3m) tall reeds and chopped them into small pieces and pumped them several hundred meters away. No barges or auxiliary equipment were required. 14

Recommend

More recommend