The HTMR100 Modular High Temperature Gas Reactor program

1 Plant overview

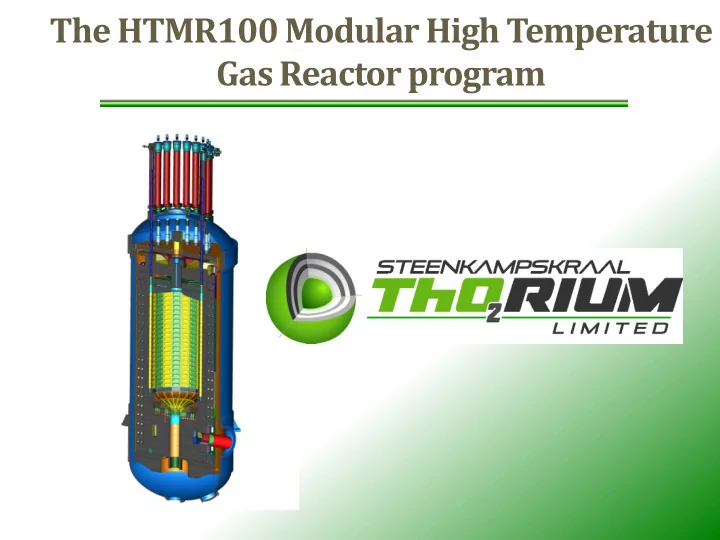

HTMR100 Reactor • The HTMR100 is a 100MW th helium cooled power plant • The heat source is based on pebble bed technology which has intrinsic safety characteristics • Power conversion is via a proven helical coil steam generator. • The HTMR100 is a CO 2 -free nuclear thermal power source that can be utilised for power generation, process heat applications, water desalination and hydrogen production. • Small size and modular construction result in relatively low cost.

HTMR100 Reactor Reflector rod drive mechanism Top access hatch Control rod Reactor pressure vessel (RPV) Top reflector Core barrel Side reflector Hot gas outlet Bottom reflector Bottom access hatch Spent fuel outlet shute

Plant Layout (Single Module) 8 9 2 1 10 16 11 13 3 12 14 4 15 6 5 7 1 Reactor building 9 Concrete vessel manufacturing 2 Auxiliary building 10 Emergency control building 3 Electrical building 11 Entrance control building 4 Turbine hall 12 Admin building 5 Conventional cooling 13 Store 6 Secured cooling 14 Radioactive waste treatment facility 7 Water storage tanks 15 Parking 8 Spent fuel storage area 16 Laydown area

Plant Layout (Multi Module)

Plant Layout (Multi Module) ; Sub-ground level

Thorium Fuel

2 Technology Basis

Technology Basis HTR-10 HTR-PM HTTR-30 (China) (China) (Japan) HTMR-100 SA

3 Safety Design Basis

Safety Design Approach 1. No Active Nuclear Safety Related Systems. The plant does not rely on active safety related systems during design basis accidents 2. Passivity by activation /de-activation e.g. open/close of a nuclear safety related valve. 3. Passive product and structures will not fail during events it is designed for. Examples are concrete structures, piping, graphite structures , vessels etc designed for earthquakes 4. Avoid high temperature gas on metallic structures, keep the high temperature gas in the graphite structures.

Safety Design Basis Plant Nuclear Safety • The plant has no active safety related fluid system to mitigate the effect of an accident. • The reactor protection system with its backup batteries, input signals and output action are safety-related . Actions are basically by valves. The plant ensure safety through ‘passive -by- activation ‘ means . • Emergency diesel-generators are non-safety related, no credit for its function during postulated design basis accidents and external events. • Residual heat removal is by natural means with active secured cooling system backup and emergency connecting point (electric and water) • The safety-related functions are grouped into a compact reactor building which can be constructed at different ground elevations. Sub-ground level protects against large airplane crash.

Safety Design Basis Continue Reactor & Primary loop intrinsic safety • Neutronically safe achieved through: Strong negative temperature coefficient which means the reactor automatically shuts down in loss of coolant event. • Weak fission product transport mechanism : helium is inert and is not activated, dust is periodically removed, He is continually purified. • No primary coolant phase change and low/slow pressure buildup with energy addition. • No possible buildup of explosive hydrogen mixtures. • No secured core cooling required; low power density, large mass to absorb energy, slender geometry to transfer residual heat by passive means

4 HTMR100 Reactor

HTMR100 Reactor Reflector rod drive Power 100MW Top access hatch mechanism Pressure 40 bar Control rod Reactor pressure vessel (RPV) Top reflector Reactor Outlet 750 °C Temperature Core barrel Power Steam Cycle Side reflector Conversion Product Heat and/or Hot gas outlet Electricity Bottom reflector Bottom access hatch Spent fuel outlet shute

HTMR100 Reactor • The advantage of smaller size is that the reactor and all components and systems can be constructed modularly and shipped to site for assembly. • Cost of scale is overcome by mass production with a high degree of factory assembly.

HTMR100 Reactor CRDMs Control rod connecting tubes Core internals Reactor pressure vessel

Reactor pressure vessel

Transportability by road

5 Steam Generator

Steam Generator Reflector rod Drive mechanism Connecting vessel (x16) Unit Reactor pressure vessel (RPV) Blowers (x2) Reactor Unit (RU) Steam outlet (x3) RPV support (x3) Steam Generator Unit (SGU) Core unloading Machine (CUM) Feedwater (x2) inlet (x3)

6 Core Structures

Core structures • Manufacturing is modularised • Pressure vessel first installed • Core Structures are Module 3 assembled in a factory and shipped in 3 modules including instrumentation Module 2 harnesses. Module 1

Ceramic Core Graphite core structures Complete assembly Upper core structures Bottom core structures

7 Power Conversion System

Power Conversion System Design philosophy • The design philosophy of the power conversion system (PCS) is the following: • Proven and widely used industrial technology should be used • Off-the-shelf components should be chosen as far as possible The chosen technology should have a relatively short installation time and require minimal maintenance

Power Conversion System without condenser Steam Generator Gearbox Unit Steam Turbine

8 Fuelling Scheme

Fuelling Scheme

9 Buildings

Reactor Building Crane Reflector rod drive mechanisms Citadel Reactor unit unit Core unloading Machine (CUM) Spent fuel cask Steam generator

Electrical building HVAC floor C & I floor Ablution Computer facilities room Control room Switchgear Entrance Security Electrical distribution floor Emergency diesel Conference room generators (x2)

Auxiliary building Chimney Health physics floor HVAC Floor Bridge to reactor building Waste processing He Purification basement and dispatch floor Fresh and spent fuel transfer tunnel

Reactor Building and Connecting Buildings

Reactor Building Coupled to the Turbine Building

Recommend

More recommend