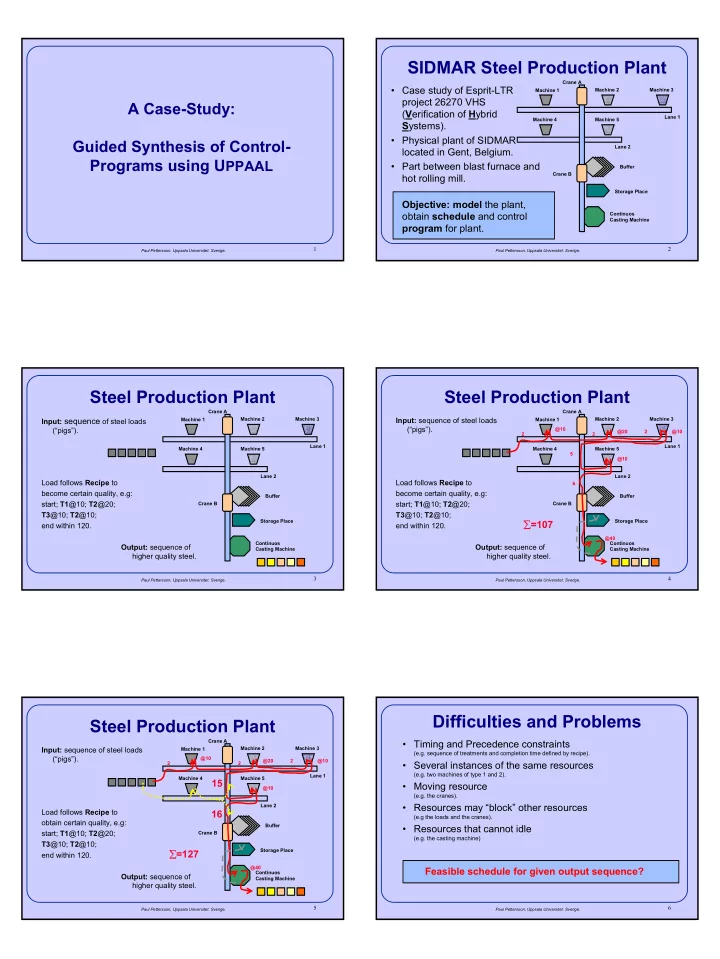

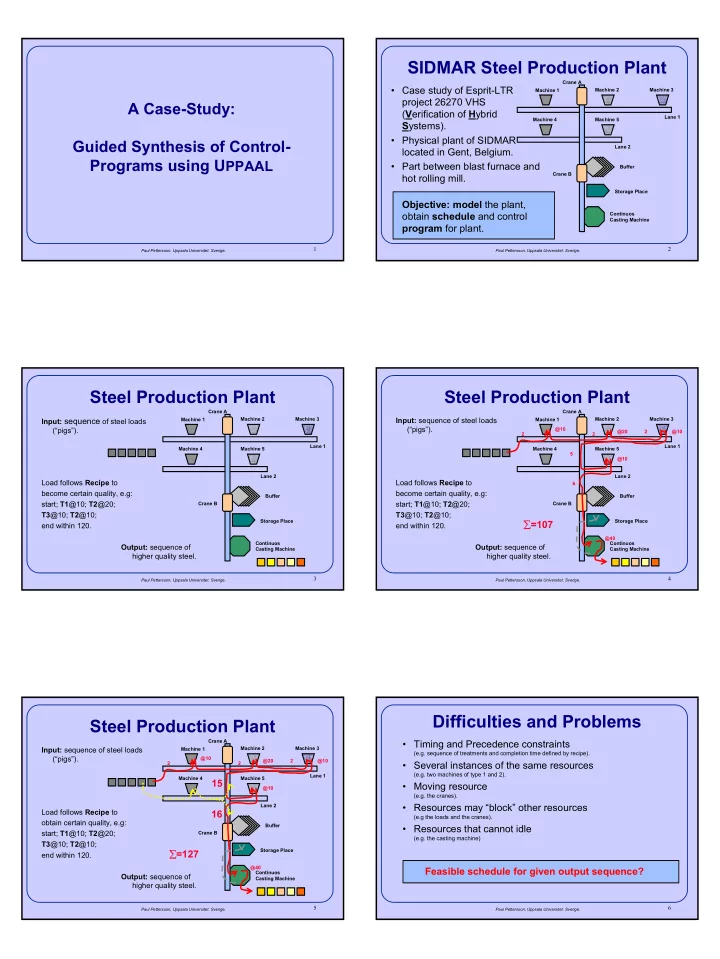

SIDMAR Steel Production Plant Crane A • Case study of Esprit-LTR Machine 2 Machine 3 Machine 1 project 26270 VHS A Case-Study: ( V erification of H ybrid Lane 1 Machine 4 Machine 5 S ystems). • Physical plant of SIDMAR Guided Synthesis of Control- Lane 2 located in Gent, Belgium. Programs using U PPAAL • Part between blast furnace and Buffer Crane B hot rolling mill. Storage Place Objective: model the plant, obtain schedule and control Continuos Casting Machine program for plant. 1 2 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige. Steel Production Plant Steel Production Plant Crane A Crane A Input: sequence of steel loads Machine 1 Machine 2 Machine 3 Input: sequence of steel loads Machine 1 Machine 2 Machine 3 (“pigs”). (“pigs”). @10 @20 2 @10 2 2 Lane 1 Lane 1 Machine 4 Machine 5 Machine 4 Machine 5 5 @10 Lane 2 Lane 2 Load follows Recipe to Load follows Recipe to 6 become certain quality, e.g: become certain quality, e.g: Buffer Buffer start; T1 @10; T2 @20; start; T1 @10; T2 @20; Crane B Crane B T3 @10; T2 @10; T3 @10; T2 @10; Storage Place ∑ =107 Storage Place end within 120. end within 120. @40 Continuos Continuos Output: sequence of Output: sequence of Casting Machine Casting Machine higher quality steel. higher quality steel. 3 4 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige. Difficulties and Problems Steel Production Plant Crane A • Timing and Precedence constraints Input: sequence of steel loads Machine 1 Machine 2 Machine 3 (e.g. sequence of treatments and completion time defined by recipe). (“pigs”). @10 @20 2 @10 2 2 • Several instances of the same resources (e.g. two machines of type 1 and 2). Lane 1 Machine 4 Machine 5 15 • Moving resource @10 (e.g. the cranes). Lane 2 • Resources may “block” other resources Load follows Recipe to 16 (e.g the loads and the cranes). obtain certain quality, e.g: Buffer • Resources that cannot idle start; T1 @10; T2 @20; Crane B (e.g. the casting machine) T3 @10; T2 @10; ∑ =127 Storage Place end within 120. @40 Feasible schedule for given output sequence? Continuos Output: sequence of Casting Machine higher quality steel. 5 6 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige.

Modus Operandi Overview of Plant Model Physical Plant Program Machine 1 & 4 Machine 2 & 5 4. Execute 1. Model plant as Production Load 3. Synthesise Machine 3 Recipe program. networks of timed Order Positions Crane A program. automata. Crane B Casting Machine Plant Model TEST BATCHES PLANT Trace 2. Reformulate scheduling as reachability Check for E<>( test.final ) and apply U PPAAL tool. U PPAAL generates diagnostic trace if property holds. 7 8 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige. Load Automaton Crane A • Models all possible movements of load in plant. • Models possible movements • Clock tRB1 used to model time consumption. of crane A. • Bit vectors posI and posII models mutex in plant. • Mutex modeled using bit vector cpos . • Clock tCA used to model time consuming horizontal and vertical movements. • Crane B is similar. 9 10 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige. Steel Recipe Production Order • Clock tot to constrain upper total time bound. • Specifies the steel qualities to be produced. • Clock t to measure duration of machine treatment. • Allows for scheduling to be reformulated as • Channel quality1! signaled when steel converted. reachability. • Reachable only with feasible schedule . • E<>( final ) 11 12 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige.

Overview Plant Model Modus Operandi • System with 5 steel loads: Physical Plant Program Parallel composition of: – 15 timed automata (6 - 60 locations), 4. Execute 1. Model plant as 3. Synthesise program. – 18 real-valued clocks, networks of timed program. automata. – 28 bounded integer variables, – 140 action channels. Plant Model Trace • Feasible schedule: approx. 320 transitions. 2. Reformulate scheduling as reachability and apply U PPAAL . Verification Result: Generating schedule for three batches impossible. 13 14 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige. Modus Operandi Guiding the Model Idea: Guide model according to chosen strategies: – enforce desired behaviors, Physical Plant Program – restrict undesired behaviors. 4. Execute 1. Model plant as 3. Synthesise program. Implementation: Annotate model with: networks of timed program. automata. – clock and integer variables, – assignments (to added clock or variable), and Plant Model – guards (to any clock or variable). Trace 2. Add guides to 3. Reformulate plant model to scheduling as reachability restrict behaviour. and apply U PPAAL . Fact: Trace of guided model is guaranteed to be trace of unguided Guided Plant Model model. 15 16 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige. General Strategies Guided Plant Model • Recipes: Recipe: • Enforce desired behaviours: – enter new loads in plant based on – greedy strategy, whenever possible, move closer to goal. production order, • Restrict undesired behaviours: – define local goals for load, – reduce point-less moving. – back-propagated time bounds. • Reduce the number of non-deterministic choices: • Cranes, if: – define local goal and chose one particular way to reach this goal. – busy : following load strategy, – idle : if there is a load to pick up, OR if blocking other crane. 17 18 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige.

Guided Load Model “Verification” Results • Greedy w.r.t. local goal (defined by recipe). • Parallel system with: 15 automata, 18 clocks, 33 integers, 140 action channels. • Less point-less moving and non-determinism. • Guided plant model (with different recipes): – 3 batches consumes 1 sec, 2MB, – 5 batches consumes 42 sec, 4.5 MB. • Plant model without guides : – 3 batches impossible! • Scheduling problem reformulated as reachability and analysed with U PPAAL on Pentium 150 MHz equipped with 32 MB RAM (+ 64 MB Swap) . 19 20 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige. Experiment Modus Operandi A l l G u i d e s S o m e G u i d e s N o G u i d e s n B F S D F S B S H B F S D F S B S H B F S D F S B S H s M B s M B s M B s M B s M B s M B s M B s M B s M B Physical Plant Program 1 0,1 0,9 0,1 0,9 0,1 0,9 0,1 0,9 0,1 0,9 0,1 0,9 3,2 6,1 0,8 2,2 3.9 3.3 2 18,4 36,4 0,1 1 0,1 1,1 - - 4,4 7,8 7,8 1,2 - - 19,5 36,1 - - 4. Execute 1. Model plant as 3 - - 3,2 6,5 3,4 1,4 - - 72,4 92,1 901 3,4 - - - - - - 4. Synthesise program. networks of timed 4 - - 4 8,2 4,6 1,8 - - - - - - - - - - - - program. automata. 5 - - 5 10,2 5,5 2,2 - - - - - - - - - - - - 10 - - 13,3 25,3 16,1 9,3 - - - - - - - - - - - - 15 - - 31,6 51,2 48,1 22,2 - - - - - - - - - - - - Plant Model Trace 20 - - 61,8 89,6 332 46,1 - - - - - - - - - - - - 25 - - 104 144 87,2 83,3 - - - - - - - - - - - - 2. Add guides to 3. Reformulate 30 - - 166 216 124,2 136 - - - - - - - - - - - - plant model to scheduling as reachability 35 209 250 - - - - - - - - - - - - - - restrict behaviour. and apply U PPAAL . • BFS = breadth-first search, DFS = depth-first search, BSH = bit-state hashing, Experiment Guided Plant Model • “-” = requires >2h (on 450MHz Pentium III), >256 MB, or suitable hash-table size was not found. • System size : 2n+5 automata and 3n+3 clocks, if n=35: 75 automata and 108 clocks. • Schedule generated for n=60 on Sun Ultra with 2x300MHz with 1024MB in 2257s . 21 22 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige. LEGO Plant Model LEGO Plant Model Mindstorm RCX Brick • LEGO RCX crane a m1 m2 m3 Mindstorms. • Local controllers with control m4 m5 programs. • IR protocol for crane b remote invocation of buffer programs. • Central controller. storage central casting controller Belt/Machine Unit. 23 24 Paul Pettersson, Uppsala Universitet. Sverige. Paul Pettersson, Uppsala Universitet. Sverige.

Recommend

More recommend