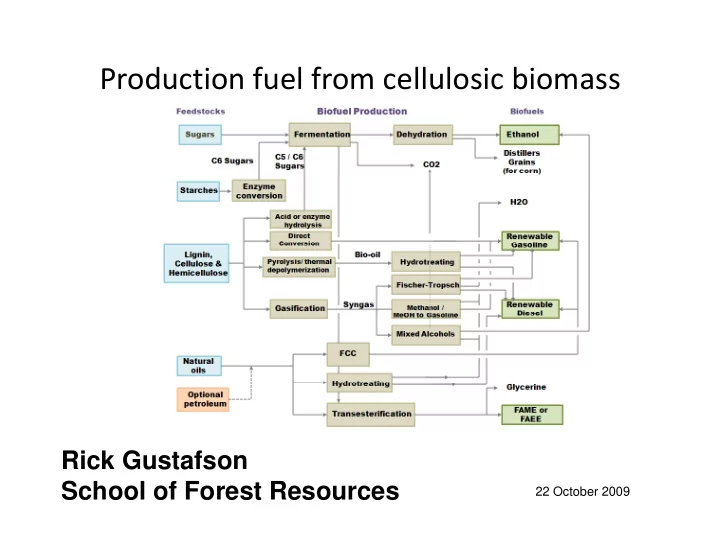

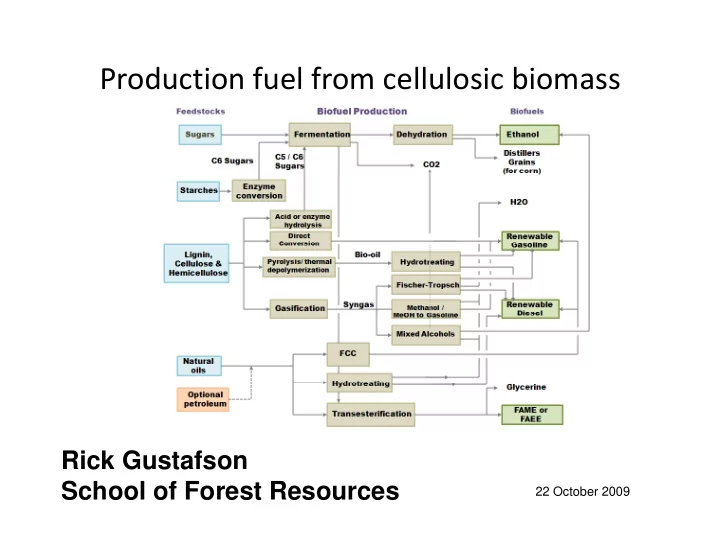

Production fuel from cellulosic biomass Ri k G Rick Gustafson t f School of Forest Resources 22 October 2009

Motivation for biofuels Motivation for biofuels Climate Change

Biomass is renewable and can be carbon neutral

Corn ethanol Cellulosic ethanol Source: National Geographic

Motivation for biofuels Motivation for biofuels Economic utilization Economic utilization of waste biomass

Motivation for biofuels Motivation for biofuels Energy Independence

http://www.nationmaster.com/red/graph/ene_oil_exp_net-energy-oil-exports-net&b_map=1#

Motivation for biofuels Motivation for biofuels Expensive oil? Running out of oil? ‘Peak Oil’ Is a Waste of Energy – NY Times 24 August 2009 BP Finds Giant Oil Field Deep in G lf Gulf of Mexico f M i NY Times 2 Sept. 2009

Washington State ‐ Climate change mitigation 33.5 M mt/2006 Fires Figure 4 4 2 Washington historic CO2e emissions by sector with fire emissions superimposed (adapted from Waterman-Hoey and Figure 4.4.2. Washington historic CO2e emissions by sector with fire emissions superimposed (adapted from Waterman-Hoey and Nothstein 2007, Wiedinmyer and Neff 2007).

Climate change mitigation: CO 2 emission goals relative to current emissions WA GHG Reduction Goals 2020 to 1990 2035 to 75% 1990 2050 to 50% 1990 2050 to 50% 1990 Waterman ‐ Hoey and Nothstein. 2007. Washington’s Greenhouse Gas Emissions: Sources and Trends ‐ 2006. WA Dept. of Community, Trade and Economic Development. Olympia, WA. 18 pp. http://www.cted.wa.gov/site/853/default.aspx

Current Market Overview Current ethanol capacity = 10.6 billion gal/year Current biodiesel capacity = 700 million gal/year Ethanol futures, $/gal Source: http://www.ethanolrfa.org/industry/statistics,

Energy Independence and Security Act 2007 (Now they are talking about 60 billion gals/year!!!!) (Now they are talking about 60 billion gals/year!!!!) 40 2005 EPAct RFS 35 Current Ethanol Production 2007 RFS - Conventional 2007 RFS - Cellulosic Biofuels 2007 RFS - Biomass-based Diesel Year) 30 2007 RFS - Unaffiliated Billion Gallons per 25 Cellulosic 20 Renewable Fuel (B 15 mated 10 Estim R Corn 5 0 0 2000 2005 2010 2015 2020 Total US oil consumption = 320 billion gals/year Total US oil imports = 220 billion gals/year

U.S. Biomass Resource Assessment • Updated resource assessment - April 2005 U d t d t A il 2005 • Jointly developed by U.S. DOE and USDA • Referred to as the “Billion Ton Study” • Current biomass production less than 500 million tons/year 13

The “Billion Ton” potential represents about 1/3 of our petroleum use when The Billion Ton potential represents about 1/3 of our petroleum use when converted to liquid fuels Billion Barrel of Oil Equivalents Based on ORNL & USDA Resource Assessment Study by Perlach et.al. (April 2005) http://www.eere.energy.gov/biomass/pdfs/final_billionton_vision_report2.pdf

Washington State situation is different Source: WSU, WA DOE. http://www.ecy.wa.gov/pubs/0507047.pdf

Replace oil with biofuels in Washington State??? 18 18 million tons of biomass available annually illi t f bi il bl ll Assume 90 gallons fuel/ton biomass Total biofuel = 1,620,000,000 gallons/year Total WA oil consumption = 6 500 000 000 gallons/year 6,500,000,000 gallons/year

Range of Biorefinery Concepts Range of Biorefinery Concepts Bi Biomass Biomass Bi Conversion Conversion C C i i Uses U Uses Feedstock Feedstock Processes Processes Fuels � Ethanol � Renewable Diesel � Mixed Alcohols Mi d Al h l � Dimethyl Ether Power � Electricity � Heat Chemicals � Plastics � Trees � Enzymatic Fermentation � Solvents � Chemical Intermediates � Grasses � Gas/liquid Fermentation � Phenolics � Agricultural Crops � Acid Hydrolysis/ � Adhesives � Furfural Fermentation � Residues � Fatty Acids � Acetic Acid � Gasification � Animal Wastes � Carbon Black � Pyrolysis � Pyrolysis � Municipal Solid Waste � Etc. M i i l S lid W t Et Food and Feed � Combustion � Co-firing 10/29/2009 17

Adapted from Holmgren etal (2008); Hydrocarbon Processing, Sep.

What is biomass made of? Representation of Cell Wall Components Cellulose Hemicelluloses Lignin Lignin

Cellulose For Chemists • Very long straight chain polymer of glucose: approximately 10 000 in a row in wood Cotton is nearly pure cellulose 10,000 in a row in wood. Cotton is nearly pure cellulose. • Cellulose molecules link up in bundles and bundles of bundles and bundles of bundles of bundles to make fibers • Cellulose forms tight bundles which are very resistant to chemical attack Cellobiose Unit CH 2 OH CH 2 OH OH β O β O OH HO HO O O O O O HO HO O β OH O CH 2 OH OH β β CH 2 OH 2 β Cellulose

Hemicelluloses for Chemists Hemicelluloses for Chemists • Branched little uncolored sugar polymers (~ 50 to g p y ( 300 sugar units) – Composition varies between wood species • 5 carbon sugars: xylose, arabinose 5 ca bo suga s: y ose, a ab ose • 6 carbon sugars: mannose, galactose, glucose • Uronic Acids: galacturonic acid, glucuronic acid • Acetyl and methoxyl groups (acetic acid & methanol) O O OH OH HO HO O O O O O O O HO O O O O OH OH O HO H 3 CO HOH 2 C OH O CO 2 H CO 2 H OH

Lignin for Chemists H 2 COH O CH 3 CH 2 CH 2 OH H 2 COH CH 2 O 28 CH H CH H C O H 2 COH CH 26 OH CH H 3 CO 27 CH 3 CH 3 OCH 3 OCH 3 16 16 O CH OCH 3 CH 6 O H 3 C C H O Carbohydrate OH 25 H 2 COH COH H OCH 3 CH 2 OH H 3 CO H C O OH C CH CH 2 OH 15 HC O O CH O H 3 C O CH 2 OH HC 14 OH H 3 CO OCH 3 O O CH CH 24 24 5 7 H 2 COH O 13 CH 2 H C O H C HC O H 3 C O CH 2 OH HC CH H COH H C O CH H 2 C CH 4 H 2 COH OH O HOH 2 HO CH C 23 HC O OCH 3 8 8 HO HO CH CH OCH 3 OCH CHO 3 CHO 12 H 3 C O H C CH 2 OH O CH H 3 C O 17 O CH H 2 C CH CH O CH O OHC CH CH 2 OH O CH HO CH O H 2 COH 22 CH 2 OH 9 O CH H 3 C O O H 3 C C H OCH 3 H 2 COH 2 10 10 H 3 C H C O O C C O H OH 18 C O H 2 COH C O 21 H 3 C O O CH HC CH H C O CH 2 OCH 3 CH 2 OH H C CH 2 19 O CH H HC O O H 3 C O H 2 COH COH H 1 11 20 O H 3 C H COH OCH 3 OH HCOH OH H 2 C O

Chemical composition Chemical composition Feedstock Glucan (cellulose) (%) Xylan (hemicellulose) (%) Lignin (%) Corn stover 37.5 22.4 17.6 Corn fiber Corn fiber 14 3 14.3 16 8 16.8 8 4 8.4 Pine wood 46.4 8.8 29.4 Poplar p 49.9 17.4 18.1 Wheat straw 38.2 21.2 23.4 Switchgrass g 31.0 20.4 17.6 Chemical composition of biomass (adapted from Mosier et al., 2005).

Approaches to cellulosic biofuels J.A. Dumesic / Catalysis Today 111 (2006) 119–132 Ethanol Ethanol

Bioconversion of biomass to ethanol (hydrolysis) Liquid q Sugars Sugars Eth Ethanol l phase Pretreatment Fermentation Biomass Lignin R Recovery Solid phase Cellulose Hydrolysis Fermentation Sugars Ethanol

Pretreatment Pretreatment Schematic of goals of pretreatment on lignocellulosic material (adapted from Hsu et al., 1980).

Various pretreatment methods Various pretreatment methods Increases Removes Alters lignin Decrystalizes Removes accessible lignin structure cellulose hemicellulose surface area surface area Uncatalyzed steam ■ ■ explosion Liquid hot water q ■ ND ■ pH controlled hot ■ ND ■ ND water Flow-through liquid ■ ■ ND ND ■ ■ hot water Dilute acid ■ ■ ■ Flow-through acid ■ ■ ■ AFEX ■ ■ ■ ■ ARP ■ ■ ■ ■ Lime ■ ND ■ ■ Adapted from Mosier et al., 2005 Major effect Minor effect

Bioconversion of biomass to ethanol (hydrolysis) Liquid q Sugars Sugars Eth Ethanol l phase Pretreatment Fermentation Biomass Lignin R Recovery Solid phase Cellulose Hydrolysis Fermentation Sugars Ethanol

E Enzyme Function y e Fu tio � There are a large number of fungal enzymes � There are a large number of fungal enzymes responsible for the breakdown of each wood component. Each enzyme plays specific roles: » Endo ‐ beta ‐ 1,4 ‐ glucanase acts within the chain, breaking it E do beta 1 4 lu a a e a t ithi the hai b eaki it into smaller units and providing more ʺ ends ʺ for CBH. » Cellobiohydrolase (CBH), acts on the end of the molecule successively cleaving off the disaccharide cellobiose successively cleaving off the disaccharide cellobiose . » Beta ‐ glucosidase (or cellobiase) which cleaves cellobiose to two glucose units.

Cellulases Cellulases Binding domain Binding domain Catalytic domain Catalytic domain Endoglucanases (EG) (EG) E d l Cellobiohydrolyses (CBH) cutting cellobiose units of the ends of the cellulose chains cutting the cellulose chains randomly

Fermentation Fermentation � Defined as: Cellular metabolism under anaerobic conditions for the production of energy and metabolic intermediates � Many organisms can “ferment” (i e grow � Many organisms can ferment (i.e., grow anaerobically) � Not all produce ethanol as an end ‐ product of p p fermentation » Butanol » Acetic acid » Acetic acid » Propionic acid » Lactic acid

Recommend

More recommend