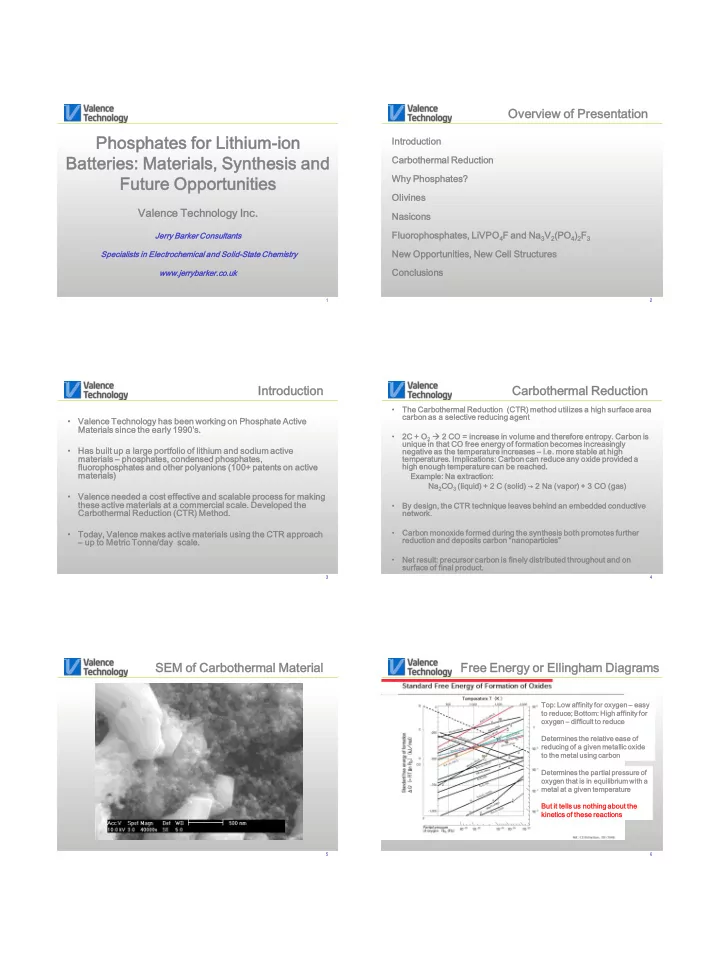

2/29/2008 Overvi view of Prese senta tati tion Phosphates for Lithium-ion ion Intro roduct ction Batteri ries: : Materials ials, , Synthesis is and Carbotherm rmal Reduct ction Future re Opport rtuniti ties Why y Phosphates? s? Olivi vines Valenc ence e Techno hnology ogy Inc. Nasico cons Fluoro rophosp sphates, s, LiVPO 4 F and Na 3 V 2 (PO (PO 4 ) 2 F 3 Jerry y Barke ker Consu sulta ltants ts New Opport rtunities, s, New Cell Struct cture res Specialists cialists in Electr troch chemica ical and Solid-Sta tate te Chemistr istry y Conclusi sions www.je .jerryb ybarker.c .co.u .uk 1 2 Introduct ctio ion Carboth thermal l Reducti tion • The Carboth thermal l Reductio ction (CTR) R) method utilizes izes a high surfa face ce area carbon as a selective ctive reducing cing agent • Valence Technology has been working on Phosphate Active Materials since the early 1990’s. • 2C + O 2 2 CO = i increase se in volume and therefo fore entropy. y. Carbon is uniqu ique in that CO free energy y of formatio tion becomes s increasing ingly ly • Has built up a large portfolio of lithium and sodium active negative tive as the temperatu ture increase ses s – i.e. more stable le at high materials – phosphates, condensed phosphates, temperatu tures. s. Impli lica catio tions: s: Carbon can reduce ce any oxide provide vided a fluorophosphates and other polyanions (100+ + patents on active high enough temperature can be reach ched. . materials) Example: le: Na extractio ction: Na Na 2 CO CO 3 (liquid) + 2 C (solid) → 2 Na (vapor) + 3 CO (gas) • Valence needed a cost effective and scalable process for making these active materials at a commercial scale. Developed the • By design ign, , the CTR techniqu ique leave ves behind ind an embedded conductive tive Carbothermal Reduction (CTR) Method. netwo twork. k. • Carbon monoxide xide formed during ing the synth thesis sis both promote tes s furth ther • Today, Valence makes active materials using the CTR approach reduction and deposits carbon “nanoparticles” – up to Metric Tonne/day scale. • Net resu sult: lt: precu curso sor carbon is finely ly distr tribu ibute ted throughout t and on surfa face of final l product. t. 3 4 SEM M of Carbothermal l Material l Free Energy y or Ellin ingham Diagrams Top: Low affinit inity for oxygen gen – easy to reduc uce; Bottom om: High h affinit inity for oxygen en – diffic icult ult to reduc uce Determ rmin ines es the relat ativ ive e ease e of reduc ucing ing of a given en metallic llic oxide de to the metal l using ng carbon bon Determ rmin ines es the partial ial pressure ure of oxygen en that at is in equilibrium ilibrium with h a metal al at a given en temperat peratur ure But it tells ls us nothing hing about ut the kinet netic ics of these e reactio ions ns 5 6 1

2/29/2008 CTR: R: Schematic tic Represe senta tatio tion Iron Blast Furnace ce lithium salt Before reaction: Mixture of carbon, metal oxide, phosphate and lithium salts Metal Oxide Reaction Mechanisms: The CO produced promotes reduction while 3 Fe 2 O 3 + CO 2 Fe 3 O 4 + CO 2 Fe 2+/3+ Fe residual carbon remains as carbon Fe Fe 3 O 4 + CO 3 3 FeO FeO + CO 2 Fe Fe 2+ 2+ “nanoparticles” FeO + CO Fe + CO 2 FeO Fe 0 Fe Metal carbon Oxide Intermediate Oxidation States: Lithium Metal Phosphate starts to form as the oxide is reduced 3+ Fe Fe Fe 3+ Fe 2+ 2+ 3+ Mn Mn 3+ Mn Mn 2+ 2+ 5+ V 3+ V 5+ 3+ Lithiated 4+ etc. Mo 6+ Mo 6+ Mo Mo 4+ Metal Net result: as the product is formed, Phosphate precursor carbon is distributed throughout and on surface of final product 7 Phosphate te Chemis istr try y Valenc ence e Studi died ed Phosph sphat ates es Nominal Specific c Material Inventor US Patent# Comments Voltage vs. Li Capacity y mAh/g LiFePO 4 3.45 140-160 J. Goodenough US 5910382 and others Olivine 5.0 Li 2 CoPO 4 F LiFe 1-x M x PO 4 3.45 140-160 J.Barker et al US 6884544 and others M = Mg, Ca, Zn Li 3 V 2 (PO 4 ) 3 3.6-4.7 197 J.Barker et al US 5871866 and others Nasicon 4.5 LiCoPO 4 LiVPO 4 F 4.2 155 J.Barker et al US 6387568 and others Triclinic Electrode Potential [V vs Li] LiVPO 4 .OH 4.1 158 J.Barker et al US 6777132 and others Triclinic 4.0 LiVPO 4 .OH LiVPO 4 F LiVP 2 O 7 4.1 116 --- --- Diphosphate LVP Li 2 MPO 4 F 4.7 143 J.Barker et al US 6964827 and others M = Co, Ni etc. 3.5 Na 2 MPO 4 F 4.7 122 J.Barker et al US 6872492 and others M = Co, Ni etc. LiVOPO 4 Phase A 3.0 Li 4 V 2 (SiO 4 )(PO 4 ) 2 3.6-4.7 260 J.Barker et al US 6136472 and others Silicophosphate LiVP 2 O 7 Li 3 V 2 (PO 4 ) 3 Na 3 V 2 (PO 4 ) 2 F 3 Li 3 V 1.5 Al 0.5 (PO 4 ) 3 3.6-4.7 203 J.Barker et al US 5871866 and others Nasicon 2.5 β -LiVOPO 4 4.0 159 J.Barker et al US 6645452 (CTR) Prepared by CTR LiFe 1-x Mg x PO 4 NaVPO 4 F 3.7 143 J.Barker et al US 6872492 and others Sodium Ion 2.0 Li 3 Ti 2 (PO 4 ) 3 Na 3 V 2 (PO 4 ) 2 F 3 3.7 192 J.Barker et al US 6872492 and others Sodium Ion Novel Phase A 3.8 ca . 150 J.Barker et al Pending Application Pending 1.5 0 50 100 150 200 Novel Phase B 3.9 ca. 140 J.Barker et al Pending Application Pending Material Specific Capacity [mAh/g] Novel Phase C 3.5 ca. 145 J.Barker et al Pending Application Pending 9 10 Phosphate Chemi mist stry y (cont..) Phosphate Safety y 5.0 Exotherm (J/g) LNO 893 J/g 4.5 LCO 570 Electrode Potential [V vs Li] 4.0 LMO 335 LiVPO 4 F LFP 124 J/g 3.5 100 200 300 400 Temperature (C) 3.0 Li 3 V 2 (PO 4 ) 3 1000 Na 3 V 2 (PO 4 ) 2 F 3 Heat Flow (J/gr) 800 2.5 LiFe 1-x Mg x PO 4 600 2.0 400 1.5 200 0 50 100 150 200 Material Specific Capacity [mAh/g] 0 LFP LVPF LVP LCP LMO LCO LNO 11 12 2

2/29/2008 Li// γ -LiV iV 2 O 5 Cycl cling ng of Graphi hite/ e// γ -Li LiV 2 O 5 Protot otypes ypes x in Li x V 2 O 5 150 1.0 0.9 0.8 0.7 0.6 0.5 0.4 0.3 0.2 0.1 0 4.5 500 Specific Discharge Capacity 125 400 4.0 300 3.5 Differential Capacity, dQ/dV [C/V] + ] 100 Electrode Potential [V vs. Li/Li 200 (mAhr/g) 3.0 Extraction 100 75 2.5 23C 0 2.0 60C 50 -100 Insertion 1.5 -200 25 1.0 -300 0.5 -400 0 0 -500 0 100 200 300 400 500 600 0 25 50 75 100 125 150 1.0 1.5 2.0 2.5 3.0 3.5 4.0 Cycle # Cathode Specific Capacity [mAh/g] + ] Electrode Potential [V vs. Li/Li 13 14 LiFe 1-x Mg Mg x PO PO 4 Li//L /LiF iFe 1-x Mg Mg x PO PO 4 4 3-Dim imens ensional ional Framew ework ork Struc ructure ure 4.5 800 Framew ework rk compris prises es PO 4 600 4.0 tetrah rahedra edra and MO 6 octahed ahedra ra Differential Capacity, dQ/dV [C/V] 400 Electrode Potential [V vs. Li] 3.5 Fe and Mg occupy upy the same e 200 crystallograph allographic ic posit itio ion 3.0 0 Cont ntrolled rolled morphology hology and partic icle le 2.5 -200 size e give e rise to fast electro rode de kinet netic ics 2.0 -400 150 150-170 70 mAh/g g @ 3.45 5 V vs. Li 1.5 -600 Metri ric Tonne produc uctio ion 1.0 -800 0 20 40 60 80 100 120 140 160 2.6 2.8 3.0 3.2 3.4 3.6 3.8 4.0 Cathode Specific Capacity [mAh/g] Electrode Potential [V vs Li] 15 16 LiFeP ePO 4 : : ex ex-si situ u XRD study y of CTR LiFeP ePO 4 : : ex ex-si situ XRD study y of CTR LiH 2 PO PO 4 + + ½ ½ Fe Fe 2 O 3 + + ½ ½ C C LiFePO 4 + H 2 O + ½ CO Filename Temp( o C) LiH 2 PO 4 Fe 2 O 3 Li 3 Fe 2 (PO 4 ) 3 LiFePO 4 Li 4 P 2 O 7 LiFeP 2 O 7 FePO 4 Fe 2 P 2 O 7 % % % % % % % % 3000 S3245 300 2.92 76.15 0.40 0.38 0.74 18.59 0 0 S3245_1 _1 400 0 43.74 3.06 1.24 0 51.959 0 0 900 S3245_2 _2 500 0 30.54 34.62 4.92 0 29.92 0 0 Intensity (A.U.) 2000 800 S3245_3 _3 600 0 3.32 1.50 91.65 0 0.84 0.46 2.24 700 600 S3245_4 _4 700 0 0.18 0.96 97.84 0 0.33 0.33 0.36 500 1000 400 S3245_5 _5 800 0 0 1.16 96.89 0 0.84 0.32 0.79 300 S3245_6 _6 900 0 0 1.32 96.73 0 0.73 0.53 0.69 Pre-mix 0 10 20 30 40 50 60 70 2 Theta. 17 18 3

Recommend

More recommend