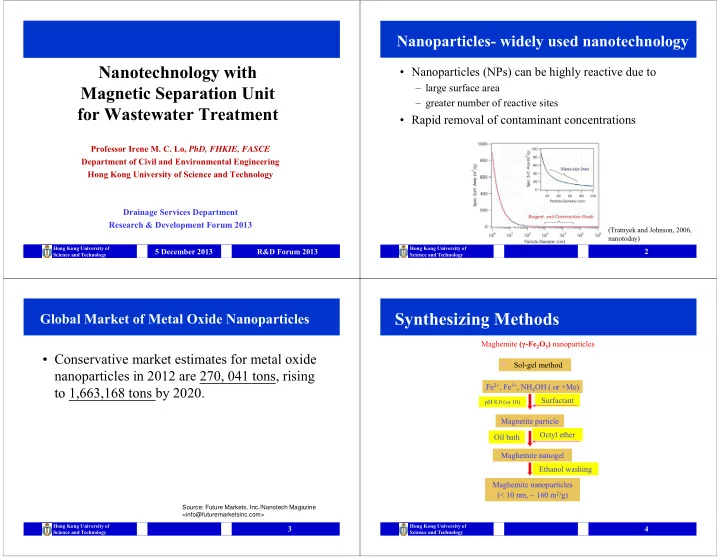

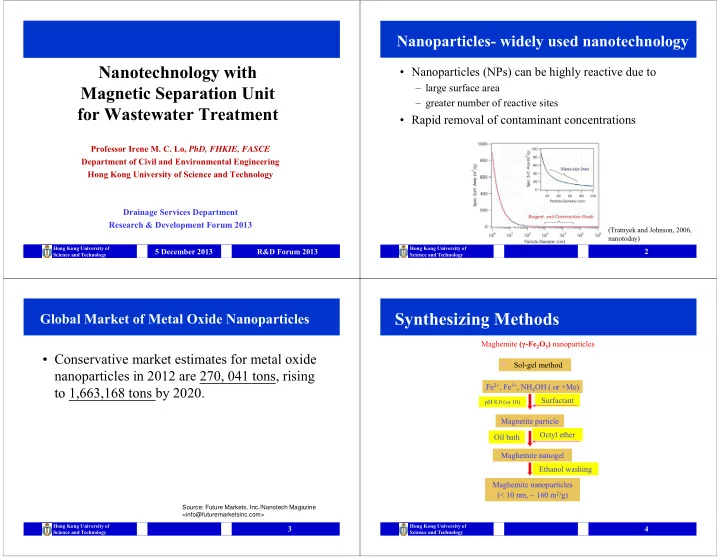

Nanoparticles- widely used nanotechnology Nanotechnology with • Nanoparticles (NPs) can be highly reactive due to – large surface area Magnetic Separation Unit – greater number of reactive sites for Wastewater Treatment • Rapid removal of contaminant concentrations Professor Irene M. C. Lo, PhD, FHKIE, FASCE Department of Civil and Environmental Engineering Hong Kong University of Science and Technology Drainage Services Department Research & Development Forum 2013 (Tratnyek and Johnson, 2006, nanotoday) Hong Kong University of Hong Kong University of Hong Kong University of 5 December 2013 R&D Forum 2013 1 2 Science and Technology Science and Technology Science and Technology Synthesizing Methods Global Market of Metal Oxide Nanoparticles Maghemite ( γ -Fe 2 O 3 ) nanoparticles • Conservative market estimates for metal oxide � Sol-gel method nanoparticles in 2012 are 270, 041 tons, rising Fe 2+ , Fe 3+ , NH 4 OH ( or +Me) to 1,663,168 tons by 2020. Surfactant pH 8.0 (or 10) Magnetite particle Octyl ether Oil bath Maghemite nanogel Ethanol washing Maghemite nanoparticles (< 10 nm, ~ 160 m 2 /g) Source: Future Markets, Inc./Nanotech Magazine <info@futuremarketsinc.com> Hong Kong University of Hong Kong University of 3 4 Science and Technology Science and Technology

Sol-gel method: γ -Fe 2 O 3 magnetic nanoparticles Characterization of Magnetic NPs US Patent 7622423 • Surface area; microporous: – BET Analyzer Removal Rate and • Particle dimension: Capacity – TEM, SEM • Morphology; chemistry; binding: Removal – XRD, AFM, XRF, XPS Mechanisms • Magnetic properties: – Vibrating sample magnetometer (VSM) – Tendency to be attracted by magnetic fields NPs Recovery 3 nm 7 nm 11 nm magnet 3nm 7nm 11nm Hong Kong University of 6 Science and Technology Application: wastewater treatment Metal adsorption by γ -Fe 2 O 3 magnetic NP • Iron-based nanoparticles (NPs) for removal of heavy 100 90 80 metals (Ponder et al., 2000, Environ. Sci. Technol.; Mak and Chen, 2004, Dyes Pigments) Removal efficiency(%) 70 60 Cu(II) • NPs with magnetic properties for wastewater treatment 50 Ni(II) 40 Cr(VI) removing anionic metals (Cr, As), nitrate & phosphate 30 20 (Wang and Lo, 2009, Water Res.; Tang et al., 2010, Environ. Eng. Sci.; Tang and Lo, 2013, Water Res.) 10 0 0 1 2 3 4 5 6 7 8 9 10 11 Implications for industrial pH Potential advantages applications (Hu at al. 2005, Water Res.) Large adsorption capacity Superior removal Short adsorption time Space saving Metal removal selectivity Magnetic separation Recovery/collection of NPs due to the changes in surface charges with pH Ease of desorption Regeneration of NPs for reuse Short equilibrium time (5 min) Hong Kong University of Hong Kong University of 7 8 Science and Technology Science and Technology

Problems/challenges Recovery by magnetic field Magnetic separation requirement • Recovery by magnetic field • Magnetic behaviour: superparamagnetic • Regeneration of magnetic particles • Although iron-based magnetic NPs can be recovered by magnetic field, the magnetic force decreases with the particle size decrease (Ngomsik et al., 2005, C. R. Chimie) • Very strong magnetic field is required for NPs Hong Kong University of Hong Kong University of 9 10 Science and Technology Science and Technology Recovery by magnetic field-cont. Recovery by magnetic field-cont. Magnetic hydrogels (polymeric • high removal rate microparticles) 10 μ m-contain more N,N,N’,N’- tetramethylethylenediamine • Very high Cr removal capacity functional groups- positive surface charges (TEMED) (accelerator) (200 mg/g) due to trimethyl (3-acrylamidopropyl)trimethylammonium γ -Fe 2 O 3 embedded chloride (APTMCl) (monomer) ammonium functional group potassium persulfate polymeric microparticles (KPS) (initiator) (10 μ m) 250 100 Cr(VI) removal (%) 200 Cr(VI) sorbed (mg/g) 80 60 150 N,N’-methylenebisa-crylamide (MBA) (crosslinker) 40 100 20 50 0 γ -Fe 2 O 3 embedded polymeric 0 1 2 3 4 5 0 microparticles (10 μ m) 0 50 100 150 200 Time (minutes) Equilibirum Cr(VI) aqueous concentration (mg/L) (Tang et al., 2010, Environ. Eng. Sci.) Hong Kong University of Hong Kong University of 11 12 Science and Technology Science and Technology

Problems/challenges Recovery by magnetic field-cont. 250 • Recovery by magnetic field 250 NO 3- adsorbed (mg/g) 200 200 • Regeneration of magnetic particles PO 43- adsorbed (mg/g) 150 150 γ -Fe 2 O 3 embedded 100 100 polymeric microparticles (10 μ m) 50 50 0 0 0 500 1000 1500 2000 0 500 1000 1500 2000 2500 3000 3500 4000 Equilibrium NO 3- aqueous concentration (mg/L) Equilibrium PO 43- aqueous concentration (mg/L) The maximum adsorption capacities for - is found to be 187.73 mg/g and for NO 3 3- to be 226.89 mg/g . PO 4 Hong Kong University of Hong Kong University of 13 14 Science and Technology Science and Technology Regeneration (from batch study) Regeneration (from batch study) – Cont. 1 st adsorption 100 Using NaCl for regeneration Batch study Effluent Cr conc. (mg/L) Cr removal efficiency 1.5 Cr removal efficiency (%) 98 96 1 1 g/L magnetic hydrogel in 80 mL = 0.08 g 94 Effluent Cr conc. 0.5 92 Influent-to-regeneration solution ratio (v:v): 80 + 80 : 2 + 2 = 160 : 4 = 40:1 0 90 2 nd adsorption 100 Vol. Duration Effluent Cr conc. (mg/L) 1.5 Process Conc. Cr removal efficiency (%) 98 Cr removal efficiency γ -Fe 2 O 3 embedded (mL) (min) 96 polymeric microparticles 1 st 20 mg/L 1 80 15 Adsorption Cr(VI) 94 Effluent Cr conc. 0.5 2 nd 20 mg/L 92 80 15 Adsorption Cr(VI) • Cr(VI) is adsorbed via a weak electrostatic interaction (ion 0 90 3 M 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 Desorption 2+2* 15 + 15* No. of cycle of adsorption-desorption NaCl exchange). So a reversible process. Desorption 700 600 Cr recovery conc. (mg/L) • High Cr(VI) recovery after 3 consecutive cycles of the 500 adsorption-desorption process 400 300 200 (Tang et al., 2010, Environ. Eng. Sci.) 100 0 Hong Kong University of Hong Kong University of 15 16 Science and Technology Science and Technology

Prototype Treatment Unit (5 L) – Prototype Treatment System (5 L) Removal and Separation 2.0 • Using magnetic 100 Effluent Cr conc. Cr removal efficiency particles for wastewater Cr removal efficiency (%) Effluent Cr conc. (mg/L) 1.5 95 treatment 1.0 90 1. Adsorption 0.5 85 • Removal efficiency 0.0 80 2. Particle ~ 97-96% 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 No. of cycle of adsorption-desorption Separation 100 • Separation efficiency Separation efficiency (%) 95 ~ 98.5% 3. Desorption (regeneration) 90 • Stable performance 85 maintained for 20 cycles 4. Particle Recovery 80 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 No. of cycle of adsorption-desorption Hong Kong University of Hong Kong University of 17 18 Science and Technology Science and Technology Patent Prototype Treatment Unit (5 L) - Regeneration • 3M NaCl was used for 250 Filed the Patent (FI-130018-60:66/C) in China in regeneration Cr recovery conc. (mg/L) 200 February 2013 for the invention entitled • Cr recovery 150 concentration 100 “ Magnetic Separation Unit for Separating Magnetic maintained at around 50 180 mg/L Nano- or Micro-particles from Treated Water in a 0 Water or Wastewater Treatment System ” 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 No. of cycle of adsorption-desorption (Ref.: TTC.PA.0582). Hong Kong University of Hong Kong University of 19 20 Science and Technology Science and Technology

Hong Kong University of Science and Technology Hong Kong University of 21 Science and Technology

Recommend

More recommend