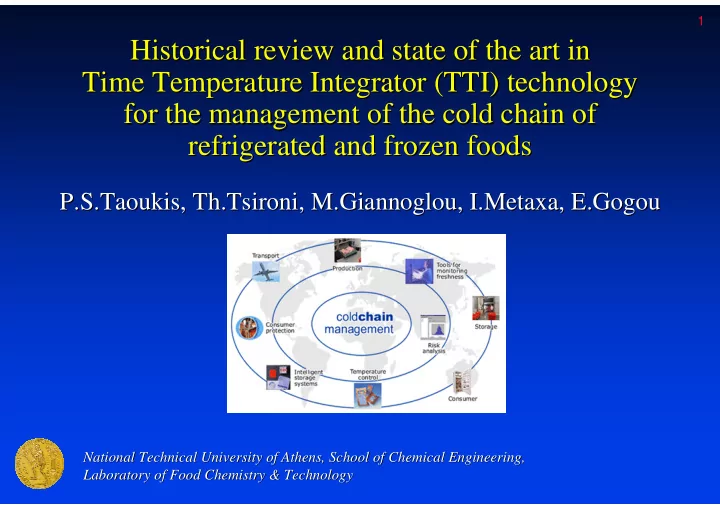

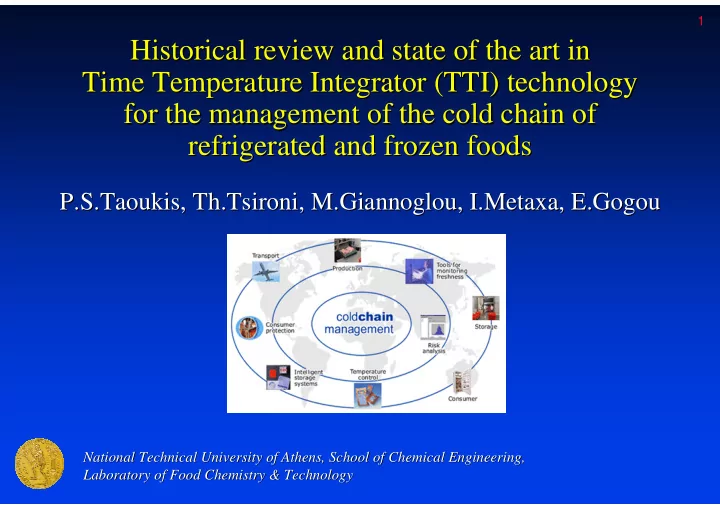

1 Historical review and state of the art in Historical review and state of the art in Time Temperature Integrator (TTI) technology Time Temperature Integrator (TTI) technology for the management of the cold chain of for the management of the cold chain of refrigerated and frozen foods refrigerated and frozen foods P.S.Taoukis, , Th.Tsironi Th.Tsironi, , M.Giannoglou M.Giannoglou, , I.Metaxa I.Metaxa, , E.Gogou E.Gogou P.S.Taoukis National Technical University of Athens, , School of Chemical Engineering, School of Chemical Engineering, National Technical University of Athens Laboratory of Food Chemistry & Technology Laboratory of Food Chemistry & Technology

2 FOOD QUALITY ASSURANCE Current philosophy : � Decrease of focus on end product testing and verification traditional cornerstones of quality and regulatory control � Development and application of structured quality assurance systems based on prevention by monitoring, controlling and recording of critical parameters through product’s entire life cycle INTRODUCTION

3 Monitoring tools for chill chain Need for development of practical systems to monitor, record and translate the effect of temperature from production to consumption. Time Temperature Integrators (TTI) A prerequisite for effective application of a TTI based control system is the determination and kinetic study and modeling of the food quality loss indices and of the response of the TTI. INTRODUCTION

4 Active packaging vs Intelligent (Smart) packaging Direct Quality Indicators vs Indirect Quality Indicators Time Temperature Integrators (TTI)

5 CHARACTERISTICS OF THE ACTUAL CHILL CHAIN

6 Weak links in the chill chain Electronic dataloggers 1 st stage of the survey: Data loggers were sealed in packages of products and monitored from processing through distribution to delivery and storage in SuperMarkets all over Greece Survey for temperature conditions (1)

Temperature conditions FROM production TO the retail outlet 7 12 10 temperature 8 6 4 14 2 temperature 12 0 10 0 5000 10000 15000 20000 8 time (min) 6 4 4 3 2 2 0 1 0 5000 10000 15000 0 time (min) -1 4000 6000 8000 10000 12000

8 Conclusions from chill chain study Temperature conditions FROM production TO the retail outlet • Sharp (but short) increases of temperature (during transport) • Cases of retail storage at temperatures > 7°C • Significant temperature fluctuations

9 Survey for temperature conditions (2) Variations WITHIN the domestic refrigerator 2 st stage of the survey: 4 data loggers were distributed randomly to potential consumers to monitor variations INSIDE the refrigerator Electronic dataloggers 1 1: upper shelf 4 2 2: middle shelf 3: lower shelf 3 4: door

10 Temperature conditions IN the domestic refrigerator UP MIDDLE 15 15 DOWN DOOR temperature temperature 10 10 5 5 0 0 1000 1500 2000 2500 3000 3500 4000 4500 5000 0 1000 2000 3000 4000 time (min) time (min)

11 upper shelf middle shelf 30 % of domestic refrigerators lower shelf door 25 20 Temperature variation within 15 domestic refrigerators 10 5 0 8% -2.0 -0.8 0.3 1.5 2.7 3.8 5.0 6.2 7.3 8.5 9.7 10.8 12.0 26% 15% Temperature (°C) < 4°C 4°C<T< 6°C Average temperature of domestic refrigerators 6°C<T< 8°C (~400 cases) 8°C<T< 10°C 10°C<T< 12°C 23% 28%

12 Food Refrigeration Innovations for Safety, Consumers’ Benefit, Environmental Impact and Energy Optimisation Along the Cold Chain in Europe EC 7 th Framework RTD Project Grant agreement no.: 245288

13 Temperature variations in distribution and storage conditions Justification for continuous monitoring TTI

14 APPLICABILITY OF TTI FOR MONITORING THE CHILL CHAIN

15 TTI PRINCIPLES & APPLICATION

16 TTI: main principles Time Temperature Indicators (TTI) are simple, inexpensive devices that can show an easily measurable, time and temperature dependent change that cumulatively indicates the time-temperature history of the product from the point of manufacture to the consumer, allowing the location and the improvement of the critical points of the chill chain TYPES OF TTI Diffusion Photochemical based Polymer Microbial Enzymatic based PRINCIPLES OF TTI

17 TTI applications 1. Constant temperature monitoring of the chill chain-elucidation of the “problematic” distribution phases 2. Correlation to food quality deterioration kinetics-prediction of the remaining shelf life at ANY point of the distribution chain. 3. Improvement of the management and stock rotation system (FIFO) – introduction of Least Shelf life Out (LSFO)/ Shelf Life Decision system (SLDS).

18 Early TTI

19 Enzymatic TTI •Enzymatic TTI is based on a colour change caused by a pH decrease which is the result of a controlled enzymatic hydrolysis of a lipid substrate Enzyme and substrate are Hydrolysis of the substrate mixed by mechanically causes acid release and the pH breaking a separating drop is translated in a color barrier inside the TTI change of a pH indicator from deep green to bright yellow or orange red Enzymatic TTI colourscale

20 Microbial TTI Accepted food The food quality is not quality accepted eO R Cryolog, Gentilly, France

21 Polymer TTI Solid state polymerization reaction.

22 TimeTemp TTI DIFFUSION REACTION SYSTEM TimeTemp AS, Norway

23 Photochemical TTI UV- -Vis filter Vis filter UV Photosensitive compounds are excited and coloured by exposure at UV radiation Active material Active material Self- -adhesive label adhesive label Self Reference scale Reference scale hn D OnVu, Ciba-Freshpoint Switzerland

24 Photochemical TTI Industrial / High speed chargers O Light, 365 nm Activation N O NO 2 + NO 2 N R Heat R Fading A, colorless B, dark blue Manual � Photochromism in crystalline state chargers � Color fading and activation energies of spiropyran crystals correspond to characteristics of food spoilage

25 S M A S Development and application of a TTI based Safety Monitoring Development and application of a TTI based Safety Monitoring and Assurance System for Chilled Meat Products and Assurance System for Chilled Meat Products A European Commission Research and Technology Development Project t A European Commission Research and Technology Development Projec Quality of life and management of living resources Quality of life and management of living resources http://smas.chemeng.ntua.gr smas.chemeng.ntua.gr http://

26 FRESHLABEL FRESHLABEL Integrated Approach to enable Traceability of the Cold chain of Fresh Chilled Meat Fresh Chilled Meat Integrated Approach to enable Traceability of the Cold chain of and Fish Products by means of tailor- -made Time/Temperature Indicators made Time/Temperature Indicators and Fish Products by means of tailor http://www.freshlabel www.freshlabel/net /net http://

27 IQ- -Freshlabel Freshlabel IQ Project IQ IQ- -Freshlabel Freshlabel Project Developing novel intelligent labels for chilled and frozen food products and promoting products and promoting Developing novel intelligent labels for chilled and frozen food the influence of smart labels application on waste reduction, food quality and safety in od quality and safety in the influence of smart labels application on waste reduction, fo the European supply chains the European supply chains

28 Instrumental measurement of TTI colour X-rite Eye1pro Colorimeter Illumination D50 Measurement of visual response with CIE Lab

29 Instrumental measurement of Photochemical TTI colour 80 0 70 -2 60 -4 50 L 40 -6 a 30 -8 20 -10 10 0 -12 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 t (h) t (h) Response function 0 -5 ∆ -10 E − = kt exp -15 ∆ E -20 0 b -25 -30 ∆ = − + − + − 2 2 2 E ( L L ) ( a a ) ( b b ) -35 max min max -40 -45 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 t (h)

30 Instrumental measurement of Enzymatic TTI colour M_100U 1.2 1.0 0.8 norm((a+b) 0.6 Response function 2.5 o C 5 o C 0.4 ( ) ( ) 8 o C + − + a b a b = 10 o C min X ( ) ( ) min 15 o C + − + a b a b 0.2 max 0.0 ( ) 1 0 50 100 150 200 = F X − t(h) k t 1 + k 1 e 2

31 Kinetics of Food Quality Deterioration ( ) • Degradation of quality index Α : = f A kt Apparent Quality function reaction order Q(A)t A o -A 0 t ln(A o -A t ) 1 1/A o -1/A t 2 − − 1 m (m ≠ 1) 1 m 1 m − A A − t o m 1 • Temperature dependence of quality function: − ( ) E 1 1 = − a f A k exp A R T T ref ref FOOD SHELF LIFE MODELLING for TTI MONITORING

Recommend

More recommend