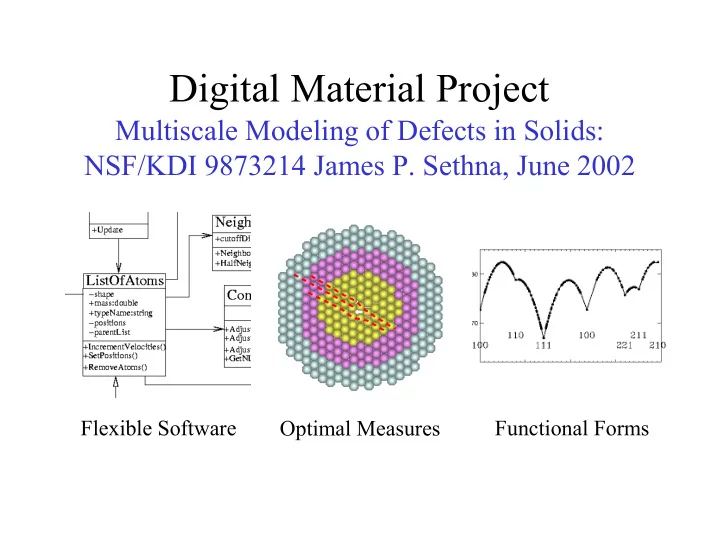

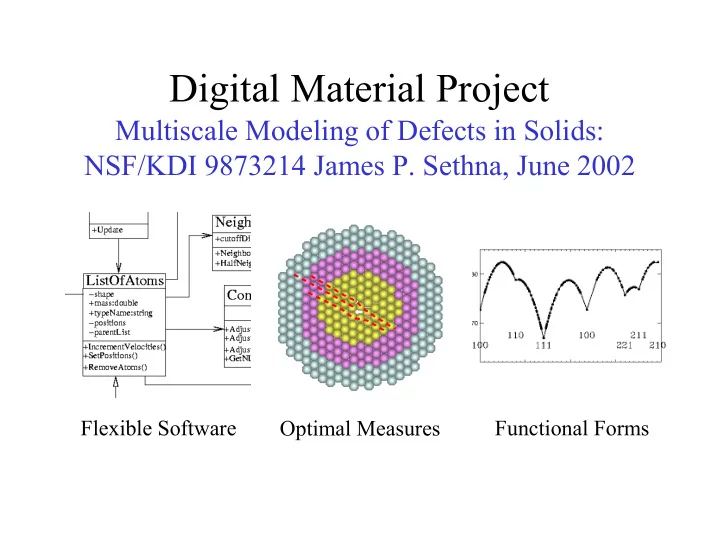

Digital Material Project Multiscale Modeling of Defects in Solids: NSF/KDI 9873214 James P. Sethna, June 2002 Flexible Software Optimal Measures Functional Forms

People: Digital Material Faculty, Post-Docs, Grad Students James P. Sethna Physics Christopher R. Myers Theory Center Veit Elser Senior personnel Nadia Adam Graduate student Anthony R. Ingraffea Civil Engineering Erik Muller Graduate student Kevin Brown Graduate student Paul R. Dawson Mechanical Engineering Ankur Mathur Graduate student Daniel Freedman Graduate student David Chen Taiwan University Mikhail Polianski Graduate student Xi Chen Graduate student Andrew J. Dolgert Cornell Theory Center Amena Siddiqi Graduate student Siew-Ann Cheong Graduate student Thierry Cretegny Swiss IT company Catherine Morris Undergrad (Markus Rauscher Max Planck Institute) Nick Bailey Post-Doc with Jacobsen (Denmark) Lance Eastgate Working with Jim Langer (UCSB) Erin Iesulauro Continuing (ITR/ASP)

Flexible Software: Digital Material Design Patterns, Python, C++ Flexible for New Algorithms • Nudged Elastic Band • Acceleration Methods • Multipoles, Interfaces • Quasicontinuum • FEM / MD interfaces Python Steering (SPASM) Efficient • Naturally Parallel • Loop Unrolling C++ Numerical Kernels Refactoring • Design for Change • Force Clean Implementation Design Patterns

Flexible Software: Digital Material Python Steering from MD3D import * from Numeric import * Spherical Cluster Initializer # Sphere of atoms atoms = DynamicListOfAtoms() # Lennard Jones potential, cut off smoothly at 2.7 units potential = CutLennardJonesPotential() # Sphere of diameter = 2*radius, in box of side 5*radius # fcc has unit cell = sqrt(2) times interatomic spacing latticeConstant = potential.GetLengthScale()*sqrt(2.0) lattice = FCCLattice(latticeConstant) radius = 2.5 * latticeConstant # Put atoms in periodic boundary conditions ([0,L]x[0,L]x[0,L]) bc = SmartPeriodicBoundaryConditions() bc.SetLength(array([1, 1, 1.])*radius*5) atoms.SetBoundaryConditions(bc) # Build a spherical fcc cluster of the right spacing sphericalInitializer = SphericalClusterInitializer(radius, lattice) # Set center to center of periodic boundary conditions box # sphericalInitializer.SetCenter(array([1, 1, 1.]) * radius * 1.5) sphericalInitializer.Create(atoms)

Flexible Software: Digital Material Design Patterns, Python Steering, … Molecular Dynamics, Phase-Field, Finite Elements, Quasicontinuum MD: faster than earlier Lyngby C code (learned how from Schiøtz) Flexible, Compatible: implemented quasicontinuum as MD extension Cu Interface Fracture Si Notch Fracture Quasicontinuum Dislocation EMT MEAM

Optimal Measures: Digital Material Multipoles, Meshing to Continuum: Nick Bailey Continuum Parameters • Barriers ⇒ Mobility • Multipoles ⇒ Interactions Efficient Extraction • Transition Layer/PBC Nudged Elastic Band Dislocation • Multipole Continuum Peierls Barrier • Crucial for DFT Depinning=Saddle-Node Fast Convergence w/5-15 Multipoles

Functional Forms: Digital Material Dislocation Mobility, 2D LJ: Nick Bailey Symmetries: Inverting Stress E B E B ( σ xy ) = E B (- σ xy ) – a 2 σ xy Singularities: Saddle-Node Transition σ xx E B ( σ xy ) = c 3/2 ( σ c – σ xy ) 3/2 + c 5/2 ( σ c – σ xy ) 5/2 … Physical Model: Sinusoidal Potential + Corrections σ xy Ballistic Functional Form σ c E B ( σ xx , σ yy , σ xy ) = -(a 2 /2) σ xy + (a 2 σ c / π ) × ( arcsin ( σ xy / σ c ) + Σ n A n ( 1-( σ xy / σ c ) 2 ) n+1/2 ) σ xy Taylor Series for σ c , A 1 , A 2 : Nine Parameters Total Fits Entire Range σ xx (Nine Measurements / DFT Calculations!)

Functional Forms: Digital Material Surface Energies: Thierry Cretegny Cu: Anisotropic Surface Energy Materials Properties anisotropic • Surface energy depends on surface normal (two variables) • Grain boundary toughness depends upon five variables • Cusps at low-index surfaces [T=0, grooves] Finding Good Functions: � + Broken Bond Model Af ( n ) Bf ( n ) � σ = Surface energy of copper 100 110 fit with two parameters (Other metals around 5) f ( x , y , z ) 8 (| x | | y | | z |) = + + 100 f ( x , y , z ) 4 (| x y | | x - y | | x z | | x - z | | y z | | y - z |) = + + + + + + + + 110

Functional Forms: Digital Material Functional Forms: Etching of Silicon Markus Rauscher, Thierry Cretegny, Melissa Hines, Rik Wind Etching rate jumps Etching rate are associated with has cusps at a faceting low-index transition surfaces CACTUS, FFTW First-order: nucleation CCMR, Microsoft

Recommend

More recommend