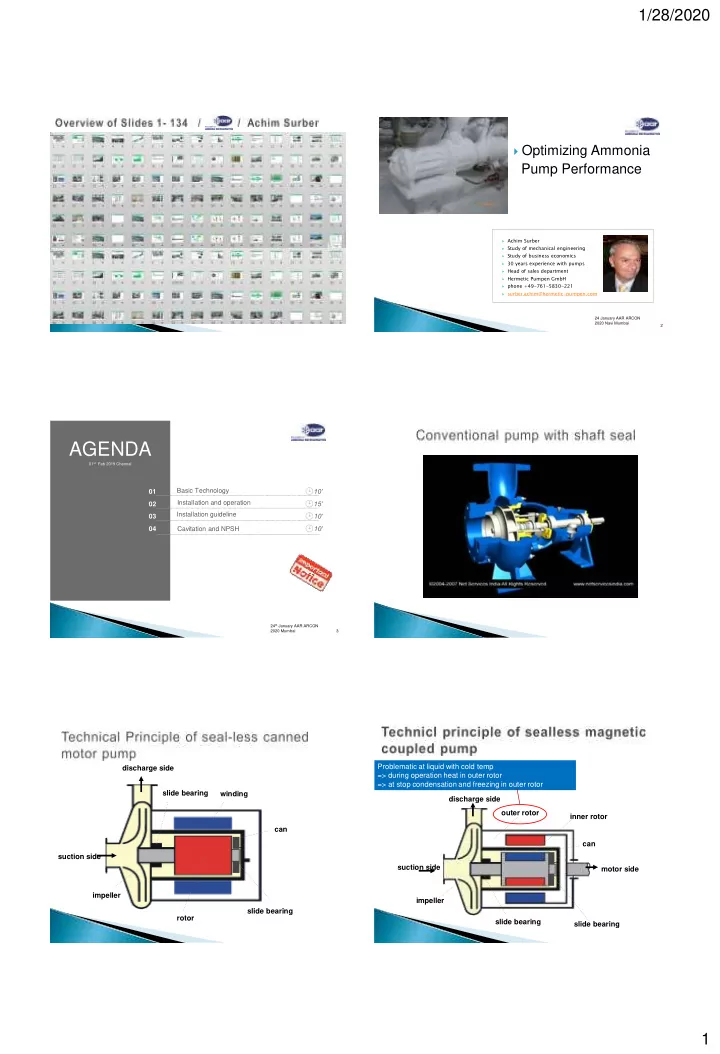

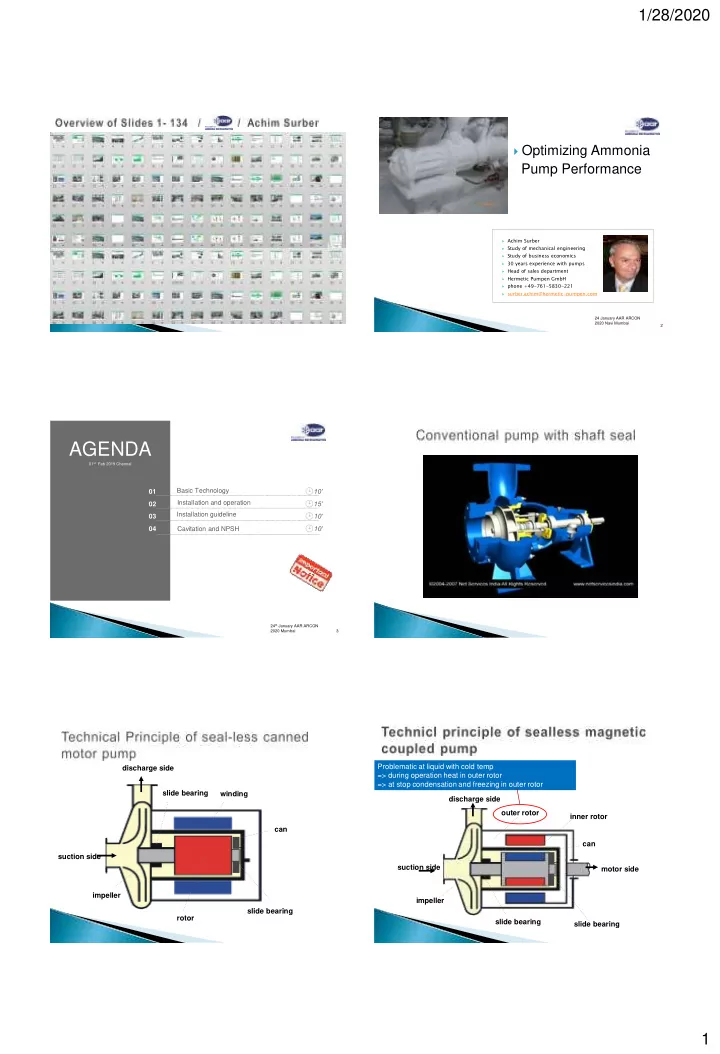

1/28/2020 1 Optimizing Ammonia Pump Performance Achim Surber Study of mechanical engineering Study of business economics 30 years experience with pumps Head of sales department Hermetic Pumpen GmbH phone +49-761-5830-221 surber.achim@hermetic-pumpen.com 24 January AAR ARCON 2020 Navi Mumbai 2 4 AGENDA 01 st Feb 2019 Chennai 01 Basic Technology 10’ Installation and operation 15’ 02 Installation guideline 10 ’ 03 10 ’ 04 Cavitation and NPSH 24 th January AAR ARCON 2020 Mumbai 3 5 6 Problematic at liquid with cold temp discharge side => during operation heat in outer rotor => at stop condensation and freezing in outer rotor slide bearing winding discharge side outer rotor inner rotor can can suction side suction side motor side impeller impeller slide bearing rotor slide bearing slide bearing 1

1/28/2020 Gap Slide bearing 24 January AAR ARCON 2020 Navi Mumbai 8 (A) (B) (C) (D) Multistage partial flow is devided at high pressure level from the last impeller (A) through the motor (B) and flows back (C) to a lower pressure level between the stages (D) Conventioal seals Seal less single stage several stages multi stage single stage Lower flow – high head Higher flow – lower head Pump efficiency conventional seal sealless Typical Flow / Head 0,5-35m3/h / max. 130m 10-60m3/h / max. 55m Head By number of stages By increase diameter Pump efficiency 10-70% 10-70% Hydraulic efficiency At higher head better Lower at higher head Motor efficiency 90-97% appr. 85% because of can NPSH Lower higher Maintenance interval 2-3 years 8-10 years (seals, roller ball bearings) Up to 30 years at constant operation Often special suction impeller Vapor pressure High vapor pressure Lower in vapor pressure handling Operational safety Leakage, mechanical seal Leakage free Seal failure Possible Non seal 24 January AAR ARCON 24 January AAR ARCON 2020 Navi Mumbai 2020 Navi Mumbai 11 12 2

1/28/2020 AGENDA 01 st Feb 2019 Chennai Basic Technology 10’ 01 Installation and operation 15’ 02 Installation guideline 10 ’ 03 10 ’ 04 Cavitation and NPSH Sealles pumps should never run dry 24 January AAR ARCON 24 January AAR ARCON 2020 Navi Mumbai 13 2020 Navi Mumbai 14 Liquid Population R717 (NH3) 80% R22 (Frigen) R744 (CO2) 12% R134a R11 R12 Propan Butan …….. 1. Compressor 2. Condenser 3. Expansion valve 4. Evaporator 24 January AAR ARCON 24 January AAR ARCON 2020 Navi Mumbai 15 2020 Navi Mumbai 16 Why Qmax Protection: Why Qmin orifice/bypass: if all regulation valves are open, • Continuous operating, even when expansion valve (1) at evaporator is closed • pressure , flow , NPSHR Automatic venting when pump is stopped after operation Protecting against over flow 24 January AAR ARCON 24 January AAR ARCON 2020 Navi Mumbai 2020 Navi Mumbai 17 3

1/28/2020 Operation outside of allowable operation range Without orifice Flow smaller than Q - min: With orifice => axial balance of pump disturbed => heating up of liquid, => vaporization in motor (mixed friction or dry running slide bearings) => increasing NPSH value Exceeding Q - max: => high power consumption => increasing NPSH value => axial balance disturbed 24 January AAR ARCON 2020 Navi Mumbai AGENDA 01 st Feb 2019 Chennai 01 Basic Technology 10’ Installation and operation 15’ 02 Installation guideline 10 ’ 03 10 ’ 04 Cavitation and NPSH 24 January AAR ARCON 24 January AAR ARCON 2020 Navi Mumbai 21 2020 Navi Mumbai 22 23 Installation VESSEL minimum level to suction pipe transverse upwards adjusted convex pipe entry 4

1/28/2020 Pressure lowering speed: pressure drop diagram Installation VESSEL steep pressure Flat pressure drop curve drop curve Boiling up of the liquid surface Liquid free of gas bubbles Installation suction pipe Suction filter is only for the commissioning period. Inlet sizing principle: mesh < 0,8mm L = 5*DNs Diameter pipe ≥ 2* Diameter suction nozzle Must be removed as soon as Flow speed: 0,3-0,5m/s possible, or must be monitoring with ∆ pressure measurement If necessary, install a sieve in the suction pipe wrong only during the start-up phase Suction pipe downwards correct 30 AGENDA ◦ on the suction side - the static pressure of the flowing liquid falls below steam pressure 01 st Feb 2019 Chennai ◦ bubbles occurs ◦ at areas of higher pressure steam bubbles will suddenly implode 10’ 01 Basic Technology ◦ this imploding is the cause for very high short-term pressure peaks of Installation and operation 15’ 02 up to some 1,000 bar Installation guideline 10 ’ 03 10 ’ 04 Cavitation and NPSH 24 January AAR ARCON 2020 Navi Mumbai 29 5

1/28/2020 pressure peaks of imploding bubbels lead to material erosions at areas of higher pressure, steam bubbles will suddenly implode outer diameter / end of vanes damage of impeller 33 34 How we can deduct cavitation ◦ We experience a loss in capacity ◦ We can no longer build the same head ( pressure drops, 3% value ) ◦ The efficiency drops ◦ NPSH = N et P ositive S uction H ead ◦ The cavities or bubbles will collapse when they pass into the higher regions of pressure causing noise, vibration ◦ If the static pressure in the suction nozzle falls below the vapor pressure of the flowing liquid CAVITATION occurs. ◦ The NPSH value helps to describe and avoid such situation Picture: cavitation causes excessive oscillation amplitudes, which courses are not cyclical over the timeline NPSH Two NPSH values: NPSHr = NPSH value of the pump. 1.) NPSHr = NPSH required When liquid flows into suction nozzle, the pressure falls shortly down. 2.) NPSHa = NPSH available This pressure drop is described in the NPSHr value of pump. Ps = suction pressure Pd = discharge pressure Picture: NPSHr value of pump in data sheet & in performance curve Theoretically NPSHa should be at least same level like NPSHr Pressure inside the pump must be all the time higher than the vapor pressure. For trouble free and safe operation: NPSHa > NPSHr + 0,5m 6

1/28/2020 Sealless Cavitation 01 04 No leackage Cause & Effect Less Maintenance Installation NPSH 02 05 Min & Max Flow NPSHA & NPSHR Orifices Safety Margin Guideline for Installation End 03 06 Venting Suction Conditions Filters 24 January AAR ARCON 1st Feb 2019 AAR ARCON 2020 Navi Mumbai 37 2019 Chennai 38 7

Recommend

More recommend