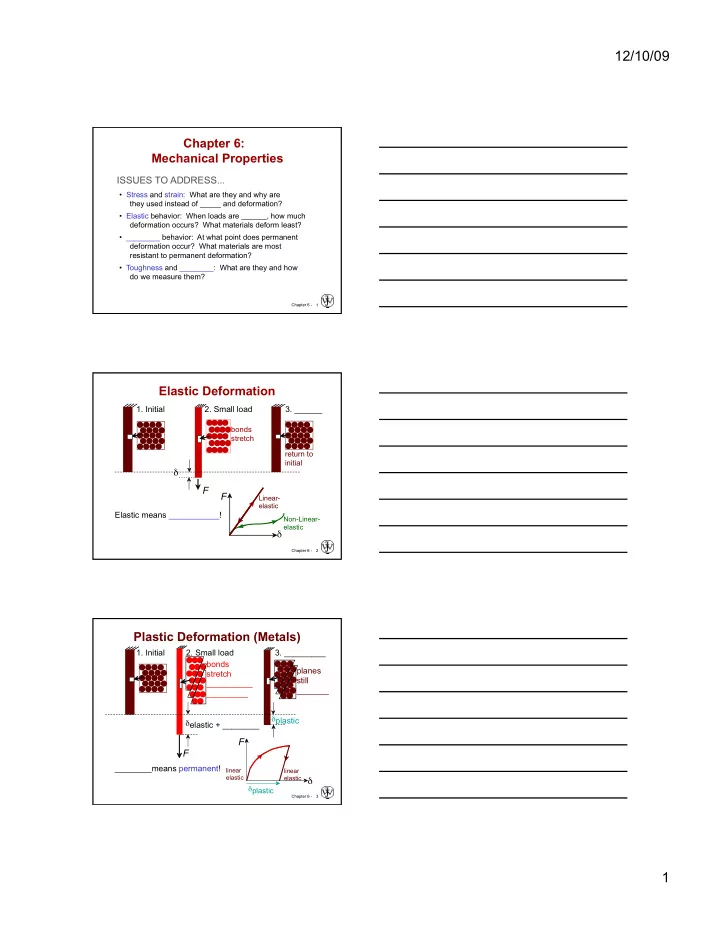

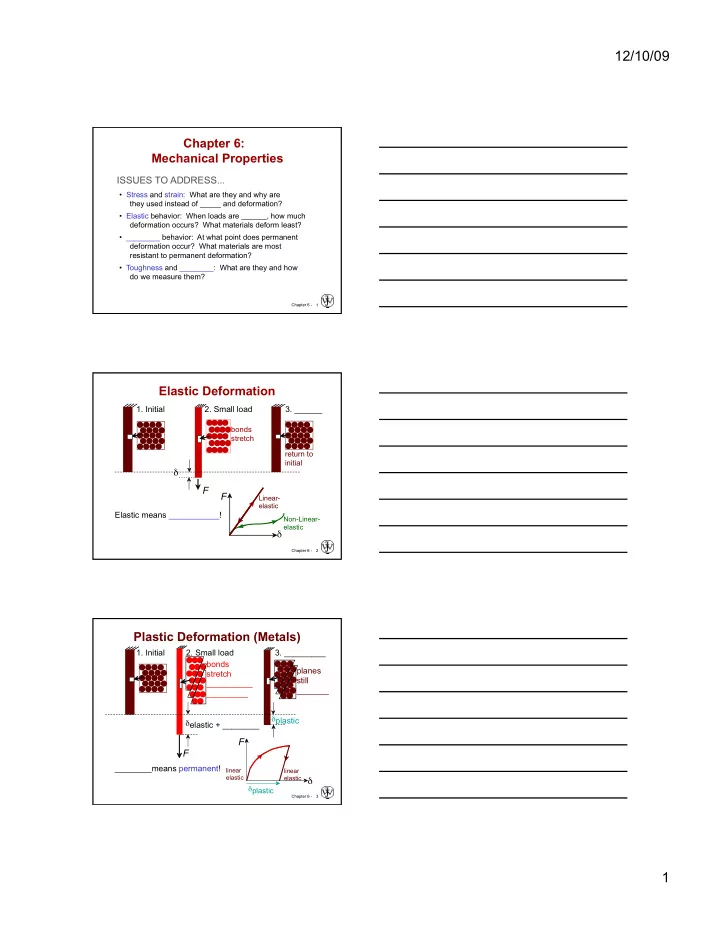

12/10/09 Chapter 6: Mechanical Properties ISSUES TO ADDRESS... • Stress and strain: What are they and why are they used instead of _____ and deformation? • Elastic behavior: When loads are ______, how much deformation occurs? What materials deform least? • ________ behavior: At what point does permanent deformation occur? What materials are most resistant to permanent deformation? • Toughness and ________: What are they and how do we measure them? Chapter 6 - 1 Elastic Deformation 1. Initial 2. Small load 3. ______ bonds stretch return to initial δ F F Linear- elastic Elastic means ___________! Non-Linear- elastic δ Chapter 6 - 2 Plastic Deformation (Metals) 1. Initial 2. Small load 3. _________ bonds planes stretch still __________ _______ _________ δ plastic δ elastic + ________ F F ________means permanent! linear linear elastic elastic δ δ plastic Chapter 6 - 3 1

12/10/09 Engineering Stress • ________ stress, σ : • ________ stress, τ : F F F t t Area, A o F s Area, A o F s F t τ = F F t s F σ = F lb N t f = A or o 2 2 A in m o _____________ ∴ Stress has units: before loading N/m 2 or lb f /in 2 Chapter 6 - 4 Common States of _______ • Simple ______: cable F F A = cross sectional o area (when _________) σ = F σ σ A o Ski lift (photo courtesy • ________(a form of shear): drive shaft P.M. Anderson) M F s A o τ A c τ = F s A o M 2 R Note: τ = M / A c R here. Chapter 6 - 5 OTHER COMMON ________STATES (i) • Simple ______________: A o Canyon Bridge, Los Alamos, NM (photo courtesy P.M. Anderson) σ = F Note: compressive Balanced Rock, Arches structure member National Park A o ( σ < 0 here). (photo courtesy P.M. Anderson) Chapter 6 - 6 2

12/10/09 OTHER COMMON STRESS STATES (ii) • Bi-axial tension: • Hydrostatic ____________: Fish under water Pressurized tank (photo courtesy (photo courtesy P.M. Anderson) P.M. Anderson) θ > 0 σ z > 0 σ < 0 σ h Chapter 6 - 7 Engineering Strain • _________ strain: • Lateral strain: /2 δ - δ ε = δ L ε L = L o L w o o w o δ /2 L • _______ strain: θ Δ x γ = Δ x / y = __ θ 90º - θ y Strain is always 90º ______________. Adapted from Fig. 6.1(a) and (c), Callister & Rethwisch 8e. Chapter 6 - 8 Stress-Strain Testing • Typical tensile test • Typical _______ __________ specimen Adapted from extensometer specimen Fig. 6.2, Callister & Rethwisch 8e. gauge length Adapted from Fig. 6.3, Callister & Rethwisch 8e. (Fig. 6.3 is taken from H.W. Hayden, W.G. Moffatt, and J. Wulff, The Structure and Properties of Materials , Vol. III, Mechanical Behavior , p. 2, John Wiley and Sons, New York, 1965.) Chapter 6 - 9 3

12/10/09 Linear Elastic Properties • ____________________, E : (also known as Young's modulus) • _________ Law: σ = E ε σ F E ε Linear- F elastic simple tension test Chapter 6 - 10 Poisson's ratio, ν ν ε L • ____________ ratio, ν : ε L ν = - ε ε - ν _____: ν ~ 0.33 ceramics: ν ~ 0.25 polymers: ν ~ 0.40 Units: ν > 0.50 ________ increases E : [GPa] or [psi] ν < 0.50 density decreases ν : dimensionless (voids form) Chapter 6 - 11 Mechanical Properties • __________ of stress strain plot (which is proportional to the elastic modulus) depends on bond _________ of metal Adapted from Fig. 6.7, Callister & Rethwisch 8e. Chapter 6 - 12 4

12/10/09 Other Elastic Properties M τ • Elastic ________ G ____________, G : simple γ torsion τ = G γ test γ M • Elastic _______ P P ___________, K: P P V Δ V K Δ P = - V o V pressure o K test: Init. vol = V o . • Special relations for _________ materials: Vol chg. = Δ V E E G = K = ______ 2(1 + ν ) Chapter 6 - 13 Young’s Moduli: Comparison Graphite Metals Polymers Composites Ceramics Alloys /fibers Semicond 1200 10 00 Diamond 8 00 6 00 Si carbide 4 00 Tungsten Carbon fibers only Al oxide Molybdenum Si nitride Steel, Ni C FRE(|| fibers)* E (GPa) 2 00 <111> Tantalum Platinum Si crystal Cu alloys <100> A ramid fibers only 10 0 Zinc, Ti 8 0 Silver, Gold A FRE(|| fibers)* Glass - soda Aluminum Glass fibers only 6 0 Based on data in Table B.2, Magnesium, G FRE(|| fibers)* Tin 4 0 Callister & Rethwisch 8e. Concrete Composite data based on GFRE* 2 0 10 9 Pa reinforced epoxy with 60 vol% CFRE * G FRE( fibers)* G raphite of aligned 10 8 carbon (CFRE), C FRE( fibers) * 6 AFRE( fibers) * aramid (AFRE), or Polyester 4 PET glass (GFRE) PS PC Epoxy only fibers. 2 PP HDP E 1 0.8 0.6 Wood( grain) PTF E 0.4 LDPE 0.2 Chapter 6 - 14 Useful Linear Elastic Relationships • Simple _________: • Simple _________: α = 2 ML δ = FL L = - ν Fw o o o δ 4 G r E A E A o π o o F M = moment = angle of twist α /2 δ A o L o L o w o 2 r o /2 δ L • Material, ___________, and loading parameters all contribute to deflection. • Larger elastic moduli minimize _________ deflection. Chapter 6 - 15 5

12/10/09 Plastic (Permanent) Deformation (at lower ____________, i.e. T < T melt /3) • Simple ________ test: ______+Plastic at larger stress engineering stress, σ Elastic initially permanent (plastic) after load is removed engineering strain, ε ε p ________ strain Adapted from Fig. 6.10(a), Callister & Rethwisch 8e. Chapter 6 - 16 Yield Strength, σ y • Stress at which ____________ plastic deformation has occurred. when ε p = 0.002 tensile stress, σ σ y = _____________ σ y Note: for 2 inch sample ε = ______ = Δ z / z ∴ Δ z = ________ engineering strain, ε = _______ ε p Adapted from Fig. 6.10(a), Callister & Rethwisch 8e. Chapter 6 - 17 Yield Strength : Comparison Graphite/ Metals/ Composites/ Ceramics/ Polymers Alloys fibers Semicond 2000 qt Steel (4140) 1000 (MPa) a Ti (5Al-2.5Sn) W (pure) in ceramic matrix and epoxy matrix composites, since 700 since in tension, fracture usually occurs before yield. 600 Cu (71500) cw in tension, fracture usually occurs before yield. 500 Mo (pure) a Steel (4140) 400 cd Room temperature Steel (1020) y 300 Hard to measure , Yield strength, σ ag Hard to measure, Al (6061) values hr Steel (1020) 200 ¨ a Ti (pure) Ta (pure) hr Cu (71500) Based on data in Table B.4, 100 Callister & Rethwisch 8e. dry a = annealed 70 PC hr = hot rolled 60 a Nylon 6,6 Al (6061) ag = aged 50 PET humid 40 PVC cd = cold drawn PP cw = cold worked 30 H DPE qt = quenched & tempered 20 LDPE Tin (pure) 10 Chapter 6 - 18 6

12/10/09 VMSE: Virtual Tensile Testing Chapter 6 - 19 Tensile Strength, TS • Maximum stress on ______________________________. Adapted from Fig. 6.11, TS Callister & Rethwisch 8e. F = fracture or σ y engineering _______ stress strength Neck – acts Typical response of a metal as stress concentrator strain engineering strain • ________: occurs when noticeable necking starts. • ________: occurs when ____________________ chains are aligned and about to break. Chapter 6 - 20 Tensile Strength: Comparison Graphite/ Metals/ Composites/ Ceramics/ Polymers Alloys fibers Semicond 5000 C fibers Aramid fib E-glass fib 3000 Tensile strength, TS (MPa) 2000 qt Steel (4140) A FRE (|| fiber) W (pure) Diamond 1000 GFRE (|| fiber) a Ti (5Al-2.5Sn) a C FRE (|| fiber) Steel (4140) cw Si nitride Cu (71500) hr Cu (71500) Al oxide Steel (1020) 300 ag Room temperature Al (6061) a Ti (pure) 200 Ta (pure) values a Al (6061) Si crystal wood(|| fiber) 100 <100> Nylon 6,6 Based on data in Table B.4, Glass-soda PC PET Callister & Rethwisch 8e. PVC GFRE ( fiber) 40 Concrete PP C FRE ( fiber) a = annealed 30 A FRE( fiber) hr = hot rolled H DPE Graphite ag = aged 20 L DPE cd = cold drawn cw = cold worked 10 qt = quenched & tempered AFRE, GFRE, & CFRE = aramid, glass, & carbon wood ( fiber) fiber-reinforced epoxy composites, with 60 vol% fibers. 1 Chapter 6 - 21 7

12/10/09 Ductility L f - L o x 100 • Plastic _____________ at failure: % EL = L o smaller % EL E ngineering ________ stress, σ larger % EL A o L o A f L f Adapted from Fig. 6.13, Callister & Rethwisch 8e. Engineering tensile strain, ε o - A A f • Another _________________: = % RA x 100 A o Chapter 6 - 22 Toughness • Energy to break a unit volume of material • Approximate by the area under the stress-strain curve. small toughness (_____________) E ngineering tensile large toughness (______) stress, σ very small toughness Adapted from Fig. 6.13, (_________________) Callister & Rethwisch 8e. Engineering tensile strain, ε Brittle fracture: elastic energy Ductile fracture: elastic + _______ energy Chapter 6 - 23 Resilience, U r • Ability of a material to store energy – Energy stored best in _______ region ε y U r d = ∫ σ ε 0 If we assume a _______ stress-strain curve this simplifies to 1 U ≅ σ ε r y y 2 Adapted from Fig. 6.15, Callister & Rethwisch 8e. Chapter 6 - 24 8

Recommend

More recommend