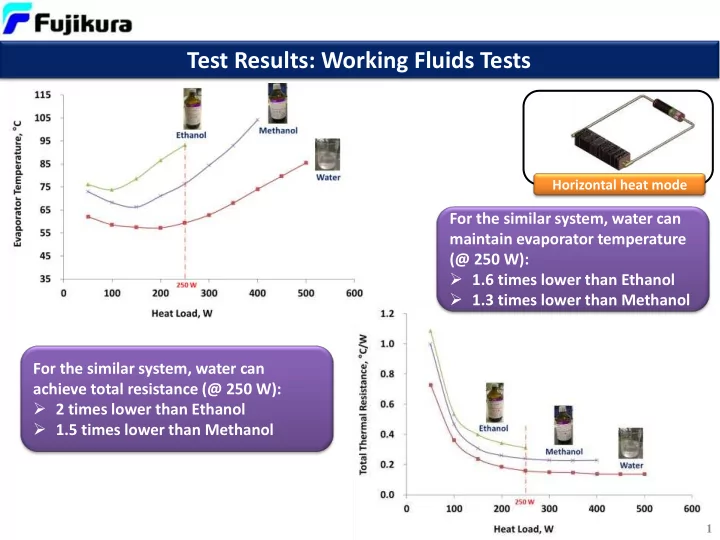

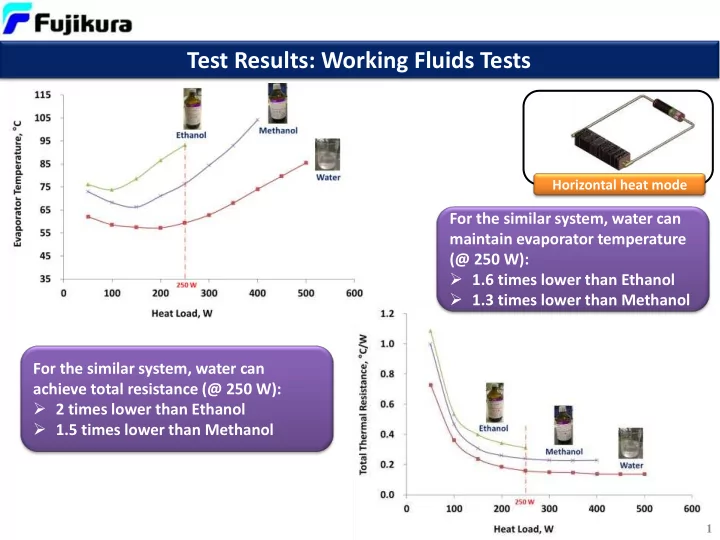

Test Results: Working Fluids Tests Horizontal heat mode For the similar system, water can maintain evaporator temperature (@ 250 W): 1.6 times lower than Ethanol 1.3 times lower than Methanol For the similar system, water can achieve total resistance (@ 250 W): 2 times lower than Ethanol 1.5 times lower than Methanol 1

Wick Flow Properties Nickel wick Titanium wick TILOP – 45 µm TC200 – 17 µm TC459 – 24 µm 80 60 5% Up 75 50 Volumetric Shrinkage, % 70 40 Porosity, % 65 30 60 20 55 10 50 0 Conditions: 900 - 950 ° C / 1 hr 600 700 800 900 1000 1100 Sintering Temperature, ºC Merits: High porosity with fine pore size Low thermal conductivity 2

Small Scale Loop Heat Pipe Performance 250 mm 150 mm 10 mm 125 mm 30 mm Small scale prototype has: High heat flux capability Flat Evaporator High thermal resistance 10 mm for lower input powers Round evaporator 3

Loop heat pipe: Technology Comparison 3 2 High heat flux Medium heat flux 1 LHP performs Liquid cooling Low heat flux superior than liquid HP & Liquid better than LHP and & HP cooling HP cooling comparable HP resistance high LHP resistance Liquid Cooling high solution 3 2 160 1 140 Temperature, °C HP 120 LC LHP#2 Heat Pipe 100 LHP#1 solution 80 60 40 Amb 20 20 W/cm2 45 W/cm2 60 W/cm2 0 mLHP 0 20 40 60 80 solution 4 Heat Load, W

Loop heat pipe for multiple heat source cooling Condenser - 2 Evaporator#1 Condenser - 1 Evaporator Liquid Line # 2 Evaporator #3 Vapour Line

Loop heat pipe with Dual Evaporator Details: Two separate loops with separate evaporator and single condenser Fin-and-tube type condenser Heat Pipe material: Copper Wick material: Sintered copper (-350 Mesh number) Working Fluid: Deionised, degassed and distilled water Operating Configuration: Condenser Above Vapour line #1 Evaporators Vapour line #2 Liquid line #1 Evaporator #1 Evaporator #2 Liquid line #2

Energy Conservation Applications 7

Heat Pipe Snow Melting System Using Geothermal Heat Heat Pipes Corrugated Flexible Heat Pipes, Stainless steel & R-134a. 3 Hps / 1 hole Installation Aomori city 8

Heat Pipe Snow Melting System Using Natural and Waste Heat Heat Source: Electric Transformer Heat Source: Underground Water Heat Source: Storage Heat Source: Geothermal Heat Source: Waste Hot Spa Water Solar Heat Partial Heating 9

Snow damage prevention system for electric pole branch wire Electric pole Wire Heat Pipe Snow Heat dissipation Soil Snow-melted hole Thermal insulation Heat collection Soil temperature : 2 to 6 deg.C Snow melting for electric pole branch wire using a heat pipe. A Photograph of Field test in Hokkaido 10

Artificial Permafrost Storage System Condenser Cold air Thermal insulation Cold Thermo-Siphon storage Frozen soil Freezing Index Food Definition of Freezing Index: Minus average temperature x days 1500 Freezing Index ( ℃ ・ Day) Edmonton Anchorage Moscow 1000 Helsinki Obihiro 500 Toronto New York Stockholm Aomori Munich Warsaw 0 Φ46 ㎜ OD 10 15 20 25 heat pipes Warmest Monthly Average temperature ℃ (216pcs) 11

Natural Cold Energy Storage by Heat Pipes for Data-Center in Cold Region Data-Center may be constructed in the Cold Region to conserve the Cooling Energy. - Winter - - Summer - Natural cold energy Cooling Fins Fins Vapor Heat Pipe GL GL Liquid Heat Pipes Ice Servers Ice storage Heat pipe does not work. Heat pipe works. (At Bottom heat mode) (At Top heat mode) 12

Heat Pipe Ice Storage System for Data Center Failure support requirement Data Center: 200 kW ~ 6 hours chiller downtime Green data center Indirect Water-to-Air support Hx system T cp-out = 32 ℃ Air mover Chiller (fan) T cp-in = 22 ℃ No running cost Cooling Tower + Smaller 22 ℃ 3 Way system Cold storage charging control during below zero size valve winter season 32 ℃ + Cold storage Lower Indirect ice/water 32 ℃ discharging line to capital cost Water/Propylene nprp Δ T =10 ℃ Glycol Hx 22 ℃ Heat Pipe Ice Storage System 13

Double Loop Tube Heat Pipe for Geothermal Extraction System Electric Power : 168 KW Electric generator Impulse Turbine Condenser & Reservoir Vapor flow Control Valve Hot water supply: Tv:200 ℃ 100 ℃ - 1,927KW Corrugate P Heat pipe OD:1m Liquid flow Showering nozzles L: 10Km Q: 2,095 KW Le:1Km Geothermal temperature :400 ℃ Rock 14

Nuclear Fuel Cooling 18

Proposed Heat Pipe ECCS System for BWR Plant 460MW-e BWR (Thermal Power:1,380KW) Heat Pipe Condenser Reactor Building Vent Concrete Chamber Reactor Vessel Vapor (282 ℃ , ECCS/ Water 66.8Kg/cm 2 ) Turbine Building Spray for Chamber Heat Pipe Turbine Generator Evaporator 282 ℃ Valve Water Fuel reservoir 180 ℃ ECCS/ High Pressure Water Spray for Core Condenser Cooling Pump Control Rod Sea Water Circulation Pump Waste water Pump Water Inlet Suppression Pool ECCS/ Low Pressure Water Water 1,750 Ton Water Spray for Core 19

Su Summa mmary y of of Hea Heat t Pipe Pipe EC ECCS CS De Design sign Vapo por r Reser eservoir oir Flo low Air ir Coo ooled led Con onde denser nser Gr Gravi vity ty Water ter Cha harge ge Tan ank Water Rea eacto ctor r Vessel essel Valv alve Valv lve Evapo Eva porator tor Liquid iquid with with nee needle dle Flo low Fuel l Rod Pr Pre-he heating z ting zon one Water C ter Cha harge ge no nozzle zzle 20

Summary Design of Heat Pipe Based ECCS Air cooled condenser Initial water charge system Reactor vessel 7m Evaporato r section Fuel rods 5m Liquid line Vapour line 17m Concrete Chamber Control rods 21

Spe Spent nt Fu Fuel el Coo Cooli ling ng Sys Syste tem m by by The hermal mal Diode Diode Hea Heat t Pipe Pipe Air ir Coo ooled led Con onde denser nser of Hea of Heat t Pipes(T Pipes(The hermal D mal Diode iode 4m 4m Function) Fun ction) Heat Pi He t Pipe pes s 1 inc 1 inch SUS h SUS-Anmo nmonium nium 12m x 12 m x 12 12m Water ter Pool ool (1 (1,400 ,400Ton ons) s) Spent Fu Spe nt Fuel B el Bun undles dles Water Le ter Level el 10m 10m 4.5m 4.5m 22

Hea Heat Pipe Specifica t Pipe Specification tion Fle lexible xible Cor Corrug ugate ted d he heat t pipe pipes Condenser Conden ser 100mm 10 0mm 8mm 8mm 4m 4m Tube: : SU SUS S tube JIS JIS G 3459-1976 1976 25A S A Schedule le 5s s OD:34 D:34.0mm, .0mm, ID: ID: Fle lexible xible region gion 30.7mm, .7mm, t t:1.65 :1.65mm mm 1.32Kg .32Kg/m /m Alum luminum inum Evapo Eva porato tor fins fins 1.5mm T 1.5mm 6m 6m Working ing fluid: fluid: Ammo Ammonium ium 23

Recommend

More recommend