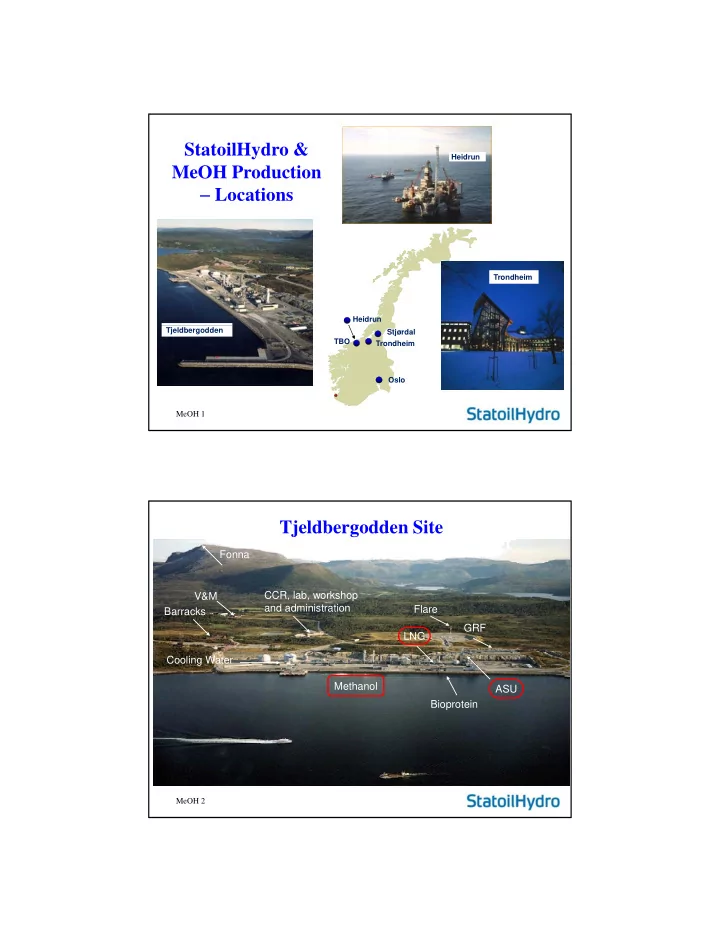

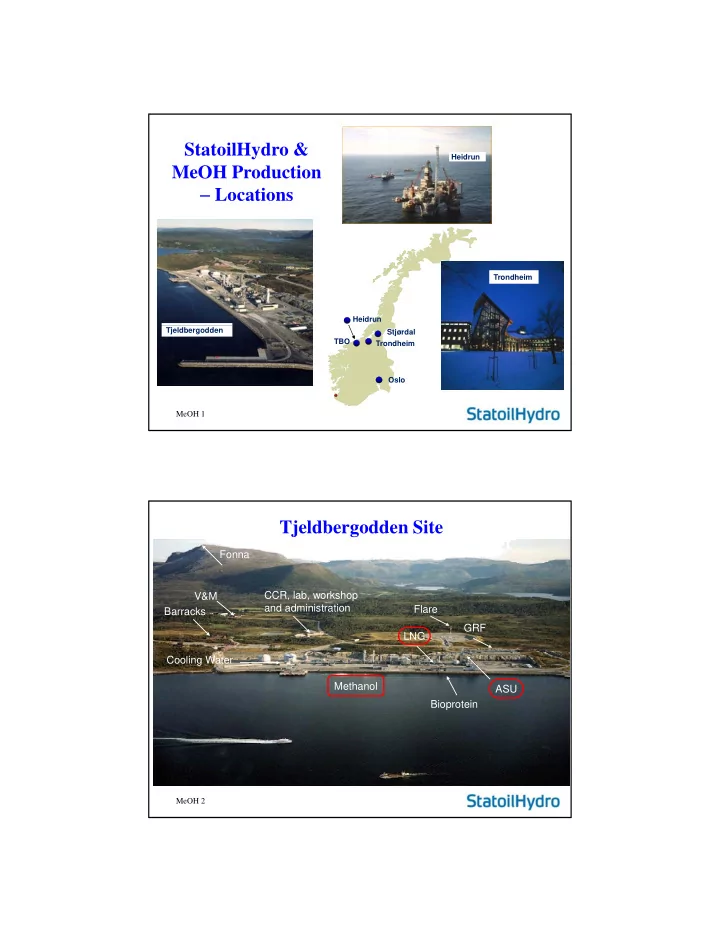

StatoilHydro & Heidrun MeOH Production Locations Trondheim Heidrun Tjeldbergodden Stjørdal TBO Trondheim Oslo MeOH 1 Tjeldbergodden Site GRF Fonna CCR, lab, workshop V&M and administration and administration Fl Flare Barracks GRF LNG Cooling Water Methanol ASU Bioprotein MeOH 2

Tjeldbergodden Industrial Park Methanol Production Industrial Gases I d t i l G (Oxygen, Nitrogen, Argon) LNG (Bioprotein - closed) (Steel Prod. – new??) (St l P d ??) Utilizing low grade Heat MeOH 3 The Methanol Plant Sulfur Removal & Reforming Gas Receiving Terminal Tank Farm Distillation MeOH Synthesis MeOH 4

Secondary Reformer Oxygen + H 2 O Gas from • Com bustion: prim.ref. H rx = -242 kJ/ mol H 2 + 1/ 2O 2 = H 2 O Burner • Reform ing and W ater Gas Shift: • Reform ing and W ater Gas Shift: H rx = 206 kJ/ mol CH 4 + H 2 O = CO + 3H 2 H rx = -42 kJ/ mol CO + H 2 O = CO 2 + H 2 • Energy: Heat is recovered in a Waste Heat Boiler (Steam) • Catalysts: Synthesis gas + H 2 O MeOH 5 Methanol Synthesis • Chem ical Reactions: CO + 2H 2 = CH 3 OH H rx = ?? kJ/ mol CO 2 + 3H 2 = CH 3 OH + H 2 O H rx = ?? kJ/ mol • Heat of Form ation Data: H 0 CO : f = -111 kJ/ mol H 0 CO 2 : f = -393 kJ/ mol H 0 H 2 : f = 0 kJ/ mol H 0 CH 3 OH : f = -201 kJ/ mol H 0 H 2 O : f = -242 kJ/ mol Answer: -90 kJ/mol and -50 kJ/mol Exothermic Reaction MeOH 6

Distillation Section with 3 Columns • Stabilizer: Removes lighter Components in raw Methanol before Distillation • HP Column: 45 % of the Distillation • LP Column: • LP Column: Completes the Purification MeOH 7 Flowsheet for MeOH Process 45 Bar 40 Bar MP steam Oxygen MeOH steam Pre- Sulfur Turbo Generator 36 Bar reformer absorber 80 Bar MeOH Primary Secundary Boiler Saturator Saturator Reformer Reformer Reformer Reformer HP HP steam 110 Bar Methanol Reactor WHB Convection Section Make-up Compressor 30 Bar Natural gas Fuel Gas Recycle 50 Bar Condensate Compr. Methanol Product to Storage Tank Stabilizer LP Column Raw MeOH Tank Water HP Column MeOH 8

Steam System for Power, Heating and Process Needs HP steam from W HB superheater (approx. values for 100% oper.) Hp-vent 160 t HP 150 t Methanol 110 bar HP-MP Boiler Boiler 10 t Let- ”Help” dow n 32-40 bar To sec.ref Boiler 135 t 3 t Mp-vent Saturator 102 t 55 t MP 110 t 12 t 45 bar 10 t MP-LP Syn. ”Bjarne” BFW Let- 10 t Gass dow n dow n Steam St turbine Add. 12 t 38 t LP Misc. GRF ASU Reboiler HP 45 t 4,5 bar MeOH 9 Air Separation Unit (ASU) Atmosphere Oxygen to Methanol Nitrogen to Storage LP Booster Compressor Column Argon Column Compander Main Heat Exchanger N2 KT VT Stripper Argon Column Argon to MSA HP Storage Column Air Air Oxygen to Storage Filter Compressor Argon Pump LOX Pumps MeOH 10

The Methanol Marked (2006) Formaldehyde Solvents Fuel MTBE Acetic Acid Others MeOH 11

Recommend

More recommend