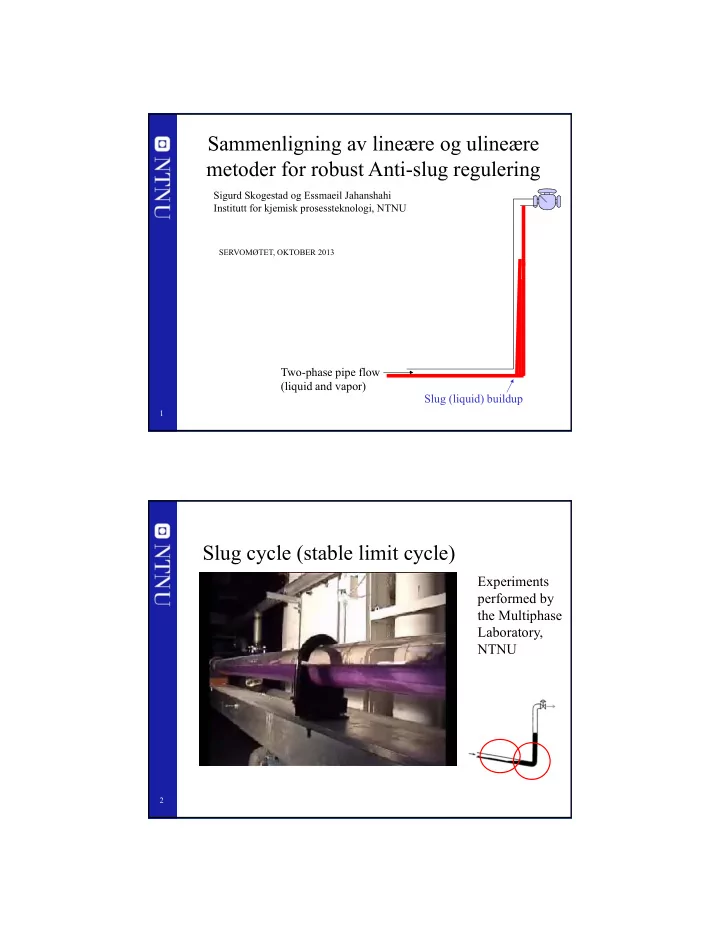

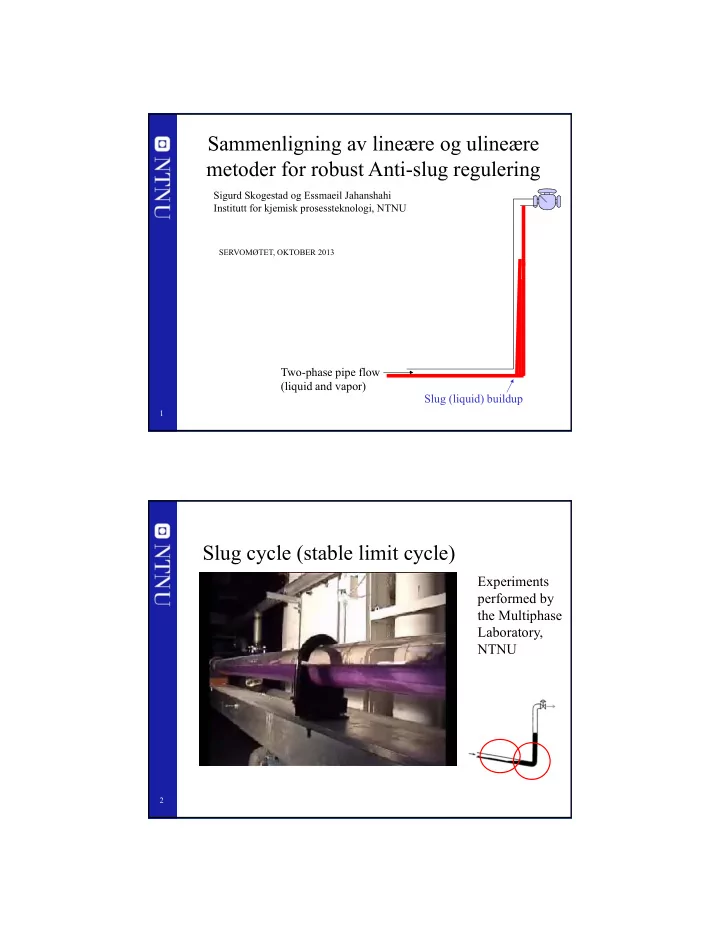

Sammenligning av lineære og ulineære metoder for robust Anti-slug regulering Sigurd Skogestad og Essmaeil Jahanshahi Institutt for kjemisk prosessteknologi, NTNU SERVOMØTET, OKTOBER 2013 Two-phase pipe flow (liquid and vapor) Slug (liquid) buildup 1 Slug cycle (stable limit cycle) Experiments performed by the Multiphase Laboratory, NTNU 2

Experimental mini-loop (2003) 3 z p 2 Experimental mini-loop Valve opening (z) = 100% p 1 SLUGGING 4

z p 2 Experimental mini-loop Valve opening (z) = 25% p 1 SLUGGING 5 z p 2 Experimental mini-loop Valve opening (z) = 15% p 1 NO SLUG 6

z Experimental mini-loop: p 2 Bifurcation diagram p 1 No slug Valve opening z % Slugging 7 How to avoid slugging? 8

z Design change p 2 Avoid slugging: 1. Close valve (but increases pressure) p 1 No slugging when valve is closed Valve opening z % 9 Design change Avoid slugging: 2. Design change to avoid slugging z p 2 p 1 10

Design change Minimize effect of slugging: 3. Build large slug-catcher z p 2 p 1 • Most common strategy in practice 11 Avoid slugging: 4. ”Active” feedback control ref PC z PT p 1 Simple PI-controller 12

Anti slug control: Mini-loop experiments p 1 [bar] z [%] Controller ON Controller OFF 13 Anti slug control: Full-scale offshore experiments at Hod-Vallhall field (Havre,1999) 14

Avoid slugging: 5. ”Active” feedback control with topside measurement? ref PC z p 2 Control is difficult (Inverse reponse = Unstable zero dynamics) 15 Summary anti slug control (2008)* • Stabilization of desired non-slug flow regime = $$$$! • Stabilization using downhole pressure simple • Stabilization using topside measurements difficult • Control can make a difference! • “Only” problem: Not sufficiently robust *Thanks to: Espen Storkaas + Heidi Sivertsen + Håkon Dahl-Olsen + Ingvald Bårdsen 16

2009-2013: Esmaeil Jahanshahi, PhD-work supported by Siemens New Experimental mini-rig P2 Top-side Air to atm. Valve Seperator Riser 3m P1 safety valve P3 FT water Buffer Mixing Point Tank Pipeline FT air P4 Subsea Valve Water Pump Water Recycle Reservoir 17 1 st step: Developed new simple 4-state model* Choke valve with opening Z m 1 : mass of gas in the pipeline G m 1 : mass of liquid in the pipeline x 3 , P 2 ,V G2 , ρ G2 , H LT P 0 L m 2 : mass of gas in the riser G w mix,out m 2 : mass of liquid in the riser L L 3 x 1 , P 1 ,V G1 , ρ G1 , H L1 x 4 L 2 h>h c w L,in w G,lp = 0 w G,in x 2 w L,lp w h L 1 h c θ State equations (mass conservations law): m w w G 1 G in , G lp , m w w L 1 L in , L lp , m w w G 2 G lp , G out , m w w L 2 L lp , L out , 18 *Based on Storkaas model

Experiment New 4-state model. Comparison with experiments: Top pressure Subsea pressure 19 Linear Control Solutions 20

Experiment Solution 1: H ∞ control based on linearizing new model Experiment, mixed-sensitivity design inlet pressure (controlled variable) 40 W KS u open-loop stable 35 min N K ( ) , N W T T K P in [ kpa ] 30 W S P 25 20 open-loop unstable 15 0 2 4 6 8 10 12 14 16 18 20 t [min] actual valve position (manipulated variable) 80 open-loop unstable Controller Off Controller On Controller Off 60 Z m [ % ] 40 20 open-loop stable 0 0 2 4 6 8 10 12 14 16 18 20 t [min] 21 Experimental linear model (new approach) Fourth-order mechanistic model: Closed-loop step-response with P-control Hankel Singular Values: Model reduction: 4 parameters need to be estimated 22

Solution 2: IMC based on identified model IMC design Block diagram for Internal Model Control system IMC for unstable systems: Model: r u y e Plant C s ( ) + _ IMC controller: 23 Experiment Solution 2: IMC based on identified model Experiment inlet pressure (controlled variable) 40 open-loop stable 35 P in [ kpa ] 30 25 20 open-loop unstable 15 0 2 4 6 8 10 12 14 16 18 20 t [min] actual valve position (manipulated variable) 80 open-loop unstable 60 Controller On Controller Off Controller Off Z m [ % ] 40 20 open-loop stable 0 0 2 4 6 8 10 12 14 16 18 20 t [min] 24

Experiment Solution 3: «Robustified» IMC using H ∞ loop shaping inlet pressure (controlled variable) open-loop stable 35 30 P in [ kpa ] 25 20 open-loop unstable 15 0 5 10 15 20 t [min] actual valve position (manipulated variable) 80 open-loop unstable 60 Controller On Controller Off Controller Off Z m [ % ] 40 20 open-loop stable 0 0 5 10 15 20 t [min] 25 Comparing linear controllers (subsea pressure) * *Controllers tuned at 30% valve opening 26

Fundamental limitation – top pressure Measuring topside pressure we can stabilize the system only in a limited range Unstable (RHP) zero dynamics of top pressure N z p p Z = 20% Z = 40% i M S ,min z p M s,min 2.1 7.0 i 1 i 0.15 RHP-Zeros Z=30% RHP-poles Z=20% 0.1 Z=15% Z=45% 0.05 Z=95% Z=60% Z=60% Z=95% Imaginary axis 0 Z=5% Z=95% Z=5% Z=95% -0.05 Z=45% Z=15% -0.1 Z=20% Z=30% -0.15 27 -0.2 -0.1 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 Real axis Nonlinear Control Solutions 28

Solution 1: observer & state feedback u c Nonlinear u c K PT observer P t State variables 29 High-Gain Observer ˆ ˆ z f z ( ) 1 1 ˆ z f ( ) z ˆ 2 2 1 ˆ ˆ z f ( ) z ˆ ( y y ) 3 3 m ˆ ˆ z f ( ) z 4 4 m RT z 1 : mass of gas in the pipeline ( m ) g r r P gp r t , m z 2 : mass of liquid in the pipeline ( m ) M ( V Lr ) lp z : pressure at top of the riser ( P ) G r 3 r t , l z 4 : mass of liquid in the riser ( m ) lr 30

State Feedback t ˆ u t ( ) K ( ( ) x t ˆ x ) K ( P ( ) r d ) c ss i in 0 K c : linear optimal gain calculated by solving Riccati equation K i : small integral gain (e.g. K i = 10 − 3 ) 31 Experiment High-gain observer – top pressure subsea pressure (estimated by observer) actual Open-Loop Stable 40 P 1 [kpa gauge] observer set-point 30 Open-Loop Unstable 20 0 5 10 15 20 25 30 35 time [min] measurement: topside pressure top-side pressure (measurement used by observer) valve opening: 20 % actual Open-Loop Stable 15 P 2 [kpa gauge] observer 10 5 Open-Loop Unstable 0 0 5 10 15 20 25 30 35 time [min] top-side valve actual position 60 Controller Controller On Controller Off Off 40 Z m [%] Open-Loop Unstable 20 Open-Loop Stable 0 0 5 10 15 20 25 30 35 time [min] 32

Experiment High-gain observer – subsea pressure subsea pressure (measurement used by observer) actual 40 Open-Loop Stable P 1 [kpa gauge] observer 30 Open-Loop Unstable 20 0 2 4 6 8 10 time [min] top-side pressure (estimated by observer) measurement: subsea pressure actual Open-Loop Stable 15 P 2 [kpa gauge] valve opening: 20 % observer 10 5 Open-Loop Unstable 0 0 2 4 6 8 10 Not working ??! time [min] top-side valve actual position 60 Controller Off 40 Z m [%] Open-Loop Unstable 20 Open-Loop Stable 0 0 2 4 6 8 10 time [min] 33 Chain of Integrators • Fast nonlinear observer using subsea pressure: Not Working??! • Fast nonlinear observer (High-gain) acts like a differentiator • Pipeline-riser system is a chain of integrator • Measuring top pressure and estimating subsea pressure is differentiating • Measuring subsea pressure and estimating top pressure is integrating P P rt in f x 1 ( ) f 2 ( ) x 34

Nonlinear observer and state feedback Summary • Anti-slug control with top-pressure is possible using fast nonlinear observers • The operating range of top pressure is still less than subsea pressure • Surprisingly, nonlinear observer is not working with subsea pressure, but a (simpler) linear observer works very fine. Subsea pressure Top Pressure Nonlinear Observer Not Working !? Working* Linear Observer Working Not Working PI Control Working Not Working Max. Valve 60% 20% *but only for small valve openings 35 Solution 2: feedback linearization P rt u c PT Nonlinear controller PT Jahanshahi, Skogestad and Grøtli, NOLCOS, 2013 36

Solution 2: feedback linearization Cascade system 37 Output-linearizing controller Stabilizing controller for riser subsystem System in normal form: : top pressure : riser-base pressure Linearizing controller: dynamics bounded Control signal to valve: 38

Experiment CV: riser-base pressure (y 1 ), Z=60% riser-base pressure (controlled variable) 40 open-loop stable set-point P rb [kPa] 30 measurement open-loop unstable 20 10 0 5 10 15 20 t [min] topside pressure (measurement used by controller) open-loop stable 15 P rt [kPa] 10 open-loop unstable 5 Gain: 0 0 5 10 15 20 t [min] actual valve position (manipulated variable) 50 min & max steady-state 100 Controller Off Controller On Controller Off 40 P in [ kpa ] Z m [%] 30 50 open-loop unstable 20 open-loop stable 0 10 0 5 10 15 20 0 10 20 30 40 50 60 70 80 90 100 t [min] Z 1 [%] 39 Solution 3: Adaptive PI Tuning 50 min & max steady-state 40 Static gain: P in [ kpa ] slope = gain 30 20 10 0 10 20 30 40 50 60 70 80 90 100 Z 1 [%] Linear valve: PI Tuning: 40

Recommend

More recommend