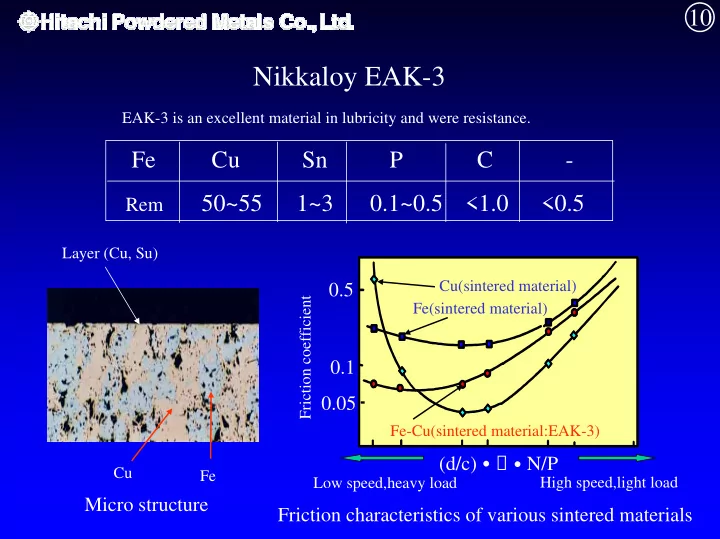

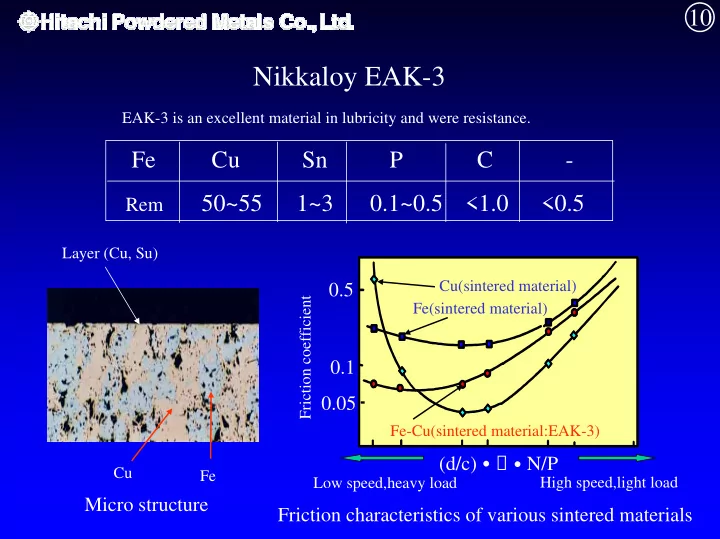

10 Nikkaloy EAK-3 EAK-3 is an excellent material in lubricity and were resistance. Fe Cu Sn P C - 50~55 1~3 0.1~0.5 <1.0 <0.5 Rem Layer (Cu, Su) Cu(sintered material) 0.5 Friction coefficient Fe(sintered material) 0.1 0.05 Fe-Cu(sintered material:EAK-3) (d/c) η N/P Cu Fe Low speed,heavy load High speed,light load Micro structure Friction characteristics of various sintered materials

11 Comparison of wear 10 Test condition Size : Φ 16 - Φ 10-10 Shaft material: S45C (heat-treatment) 8 Rotation: 5sec stop: 25sec Repetition: 20,000 cycle Wear ( μ m) Pressure: 0.3Mpa 6 Lubricant: ISO VG83 Rotational speed (k rpm) 25 4 20 15 2 10 5 0 Cu 0 Fe-Cu Fe (EAK-3) 0 5 10 15 20 25 30 35 40 45 Comparison of wear in sintered material Time (sec)

12 Dynamic pressure generation mechanism of multi-lobes bearings separation groove pressure distribution (axial) shaft pressure distribution (radial) separation groove The dynamic pressure of a multi-lobes bearings generates by the wedge action of the oil in the bearing clearance. The shaft is supported in high accuracy rotation by fluid dynamic pressure.

13 Oil flow of multi-lobes bearings Spiral groove bearing Five loves bearing oil flow (bearing surface) oil flow (shaft surface) bearing surface oil film pressure distribution shaft surface Separation grooves

14 Oil flow and pressure distribution of spiral groove bearings Direction of oil flow Pressure distribution X X X-X direction

15 Comparison of bearing stiffness and bearing loss(1) (calculation) 30 300 Herringbone bearing Bearing stiffness (kN/mm) 25 Bearing loss (mW) 250 Herringbone bearing 20 200 Five lobes bearing Five lobes bearing 15 150 10 100 50 5 0 0 0 20 40 60 80 100 0 20 40 60 80 100 Temperature ( C) Temperature ( C)

Recommend

More recommend