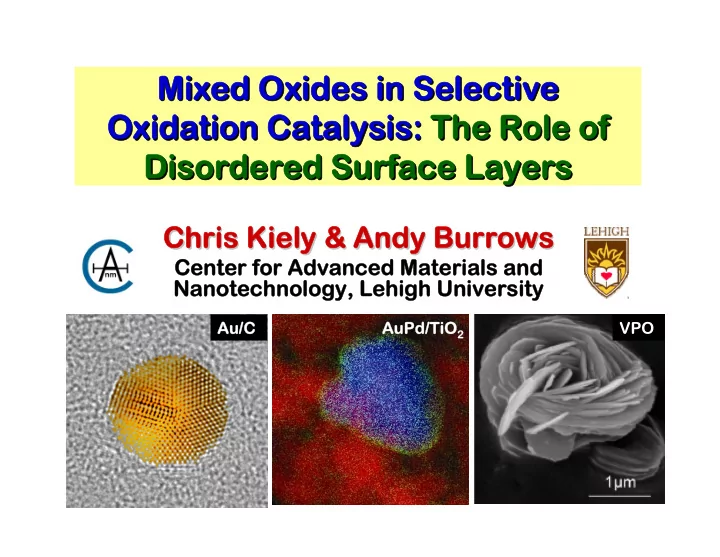

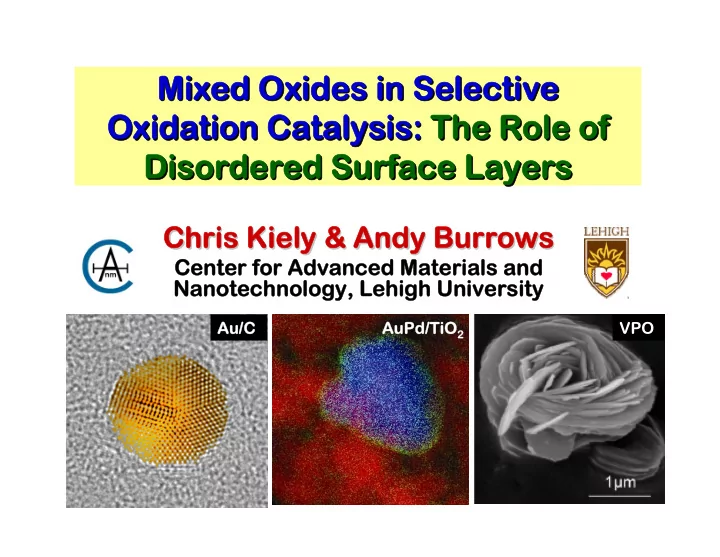

Mixed Oxides in Selective Mixed Oxides in Selective Mixed Oxides in Selective Mixed Oxides in Selective Oxidation Catalysis: Oxidation Catalysis: The Role of The Role of The Role of Oxidation Catalysis: Oxidation Catalysis: The Role of Disordered Surface Layers Disordered Surface Layers Disordered Surface Layers Disordered Surface Layers Chris Kiely & Andy Burrows Chris Kiely & Andy Burrows Chris Kiely & Andy Burrows Chris Kiely & Andy Burrows Center for Advanced Materials and Center for Advanced Materials and Nanotechnology, Lehigh University Nanotechnology, Lehigh University Au/C Au/C AuPd/Ti AuPd/TiO 2 VPO

Acknowledgements Acknowledgements Acknowledgements Acknowledgements Graham Hutchings Graham Hutchings, Leverhulme Catalysis Centre, Cardiff University, UK Jos Jose Calvino Calvino, Departmento de Quimica Inorganica, Cadiz University, Spain Jean Claude Volta, Claude Mirodatos, Institut de Recherches Jean Claude Volta, Claude Mirodatos, sur la Catalyse, Lyon, France Jens Perreg Jens Perregaard, Poul ard, Poul Hojlund Hojlund Neilson, Neilson, Haldor Topsoe, Copenhagen, Denmark Rober Robert Schl Schlogl ogl, Fritz Haber Institute, Berlin, Germany

Catalysis 101 Catalysis 101 Catalysis 101 Catalysis 101 A catalyst is a substance that increases the rate at which a chemical system reaches equilibrium without being consumed in the process. E Conversion Conv ersion - the fraction of Conv Conversion ersion E uncatalysed reactants that are E catalysed converted to products. A B Selectivity Selectivity - the fraction of Selectivity Selectivity Reactants desired product produced. Δ H reaction Lifetime Lifetime - the time period Lifetime Lifetime before a catalyst has to be C D replaced. Products Reaction co-ordinate The catalyst tends to provide an alternate reaction pathway with a lower activation energy.

Types of Heterogeneous Catalysts Types of Heterogeneous Catalysts Types of Heterogeneous Catalysts Types of Heterogeneous Catalysts Supported Metals Supported Oxides WO 3 /TiO 2 Pt-Rh/CeO 2 Nd 2 O 3 /MgO e.g. Automotive CO oxidation catalysts e.g. Selective Catalytic Reduction of NO x

Mixed Oxide Catalysts Mixed Oxide Catalysts – – Selective Oxidation Selective Oxidation Selective Oxidation Mixed Oxide Catalysts Mixed Oxide Catalysts Selective Oxidation VPO VPO Reactant Reactant Product Product Catalyst Cataly st n-butane maleic VPO anhydride propane propene VMgO propene acrolein FeSbO 4 MoBi 2 O 6 2 μ m propene acrylonitrile MoBi 2 O 6 butene butadiene MoBi 2 O 6

Oxidative Dehydrogenation of Propane (ODHP) Oxidative Dehydrogenation of Propane (ODHP) Oxidative Dehydrogenation of Propane (ODHP) Oxidative Dehydrogenation of Propane (ODHP) Desirable Desirable + + + H H 2 O Undesirable Undesirable C 3 H 8 + 5O 2 + 5O 3CO 2 + 4H 3CO + 4H 2 O • 14wt% 14wt% V in catalyst gives optimum performance V in catalyst gives optimum performance • Propane (C 3 H 8 ) conversion efficiency – Propane (C ) conversion efficiency –11% 11% • Propene (C Propene (C 3 H 6 ) selectivity – ) selectivity – 80% 80% Propene (C Propene (C 3 H 6 ) is an important feedstock chemical for the ) is an important feedstock chemical for the manufacture of isopropanol, acrol manuf cture of isopropanol, acrolei ein, acrylic acid and acrylonitrile. n, acrylic acid and acrylonitrile.

Catalyst Preparation Procedure Catalyst Preparation Procedure Catalyst Preparation Procedure Catalyst Preparation Procedure • Mg(OH) Mg(OH) 2 precipitated from magnesium nitrate solution precipitated from magnesium nitrate solution using KOH using KOH • Precipitate filtered off, Precipitate filtered off, purif purified and crushed ed and crushed • Mg(OH) Mg(OH) 2 added to hot ammonium metavanadate added to hot ammonium metavanadate (NH (NH 4 VO VO 3 ) • Suspension evaporated to dryness leaving VMgO Suspension evaporated to dryness leaving VMgO catalyst catalyst • Calcined Calcined in O in O 2 at 550 at 550 o C (6h) and then at 800 C (6h) and then at 800 o C (6h) C (6h) Reaction Conditions Reaction Conditions Reaction Conditions Reaction Conditions Fixed bed reactor: 500-550 Fixed bed reactor: 500-550 o C : atmospheric pressure C : atmospheric pressure C 3 H 8 / O / O 2 / He : 1.0 / 0.1 / 98.9 / He : 1.0 / 0.1 / 98.9

Mixed Mixed VMgO VMgO VMgO (V (V (V 5+ 5+ 5+ ) Phases ) Phases ) Phases Mixed Mixed VMgO (V 5+ ) Phases Mg Mg 3 V 2 O 8 Mg 2 V 2 O 7 Mg MgV MgV 2 O 6 Ortho- Ortho- vanadate vanadate Pyro- Pyro- vanadate vanadate Meta- Meta- vanadate vanadate Cmca (64) Cmca (64) P21/c (14) P21/c (14) C2/m (12) C2/m (12) Orthorhombi Orthorhombic (mmm) c (mmm) Monoclinic (2/m) Monoclinic (2/m) Monoclinic (2/m) Monoclinic (2/m) In isolation, none none of the pure VMgO phases is particularly active or selective for the oxidative dehydrogenation of propane.

XRD of the 14V/VMgO Catalyst XRD of the 14V/VMgO Catalyst XRD of the 14V/VMgO Catalyst XRD of the 14V/VMgO Catalyst • To study the interactions between the constituent phases To study the interactions between the constituent phases of the VMgO of the VMgO catalyst catalyst • To f To follow any structural change llow any structural changes that occur under typical s that occur under typical reaction conditions reaction conditions

Microstructure of the 14V/VMgO Catalyst Microstructure of the 14V/VMgO Catalyst Microstructure of the 14V/VMgO Catalyst Microstructure of the 14V/VMgO Catalyst [100] [100] Mg 3 V 2 O 8 Minority phase Minority phase [121] [121] Mg 3 V 2 O 8 MgO Mg 2 V 2 O 7 Trace phase Trace phase

MgO MgO Component of the 14V/VMgO Catalyst Component of the 14V/VMgO Catalyst Component of the 14V/VMgO Catalyst MgO MgO Component of the 14V/VMgO Catalyst 50nm 50nm 50nm 50nm [111] [111] [111] [111] [111] [111] [111] [111] [200] [200] [200] [200] MgO [011] MgO [011] 011] MgO MgO 011] 5nm 5nm 5nm 5nm

MgO MgO Facet Structure Facet Structure Facet Structure MgO MgO Facet Structure 14V/VMgO 14V/VMgO 14V/VMgO 14V/VMgO 10nm 10nm 10nm 10nm 10nm 10nm 10nm 10nm {100} neutral {100} neutral {100} neutral {100} neutral {111} polar {111} polar {111} polar {111} polar facets facets facet facet facets facets facet facet

Brucite Brucite – – Mg(OH) Mg(OH) Mg(OH) 2 Magnesia Magnesia - - MgO MgO MgO Brucite Brucite Mg(OH) Magnesia Magnesia MgO 2 Hexagonal Hexagonal Hexagonal Hexagonal Cubic Cubic Cubic Cubic a=0.314nm a=0.314n a=0.314nm a=0.314n a=0.423n a=0.423nm a=0.423n a=0.423nm c=0.476n c=0.476nm c=0.476nm c=0.476n

Brucite Brucite to Magnesia Transformation to Magnesia Transformation to Magnesia Transformation Brucite Brucite to Magnesia Transformation Bruci Br ucite 300 300 o 300 300 o C C Br Bruci ucite 15nm 15nm 15nm 15nm 15nm 15nm 15nm 15nm 500 500 o C 800 800 o C 500 500 o C 800 800 o C 15nm 15nm 15nm 15nm 10nm 10nm 10nm 10nm Magnesia Magnesia Magnesia Magnesia

Thermogravimetric Thermogravimetric an an analysis of alysis of brucite brucite brucite decomposition decomposition decomposition Thermogravimetric Thermogravimetric analysis of alysis of brucite decomposition 30wt% weight loss at ~420 o C as water of hydration is lost Relative stability of Relative stability of hydroxylated hydroxylated hydroxylated MgO MgO MgO surfaces surfaces surfaces Relative stability of Relative stability of hydroxylated MgO surfaces Polar surface stabilized a adsorbed –OH groups De Leeuw et al. J.Phys.Chem, 99 99, (1995), 17219

XRD comparison of the 14V/VMgO catalyst in the XRD comparison of the 14V/VMgO catalyst in the XRD comparison of the 14V/VMgO catalyst in the XRD comparison of the 14V/VMgO catalyst in the unused and used state unused and used state unused and used state unused and used state

In In- -situ XRD analysis of the 14V/VMgO catalyst under situ XRD analysis of the 14V/VMgO catalyst under situ XRD analysis of the 14V/VMgO catalyst under In In situ XRD analysis of the 14V/VMgO catalyst under redox redox cycling cycling cycling redox redox cycling Is a spinel-type phase form Is a spinel-type phase formed on ed on reduction? reduction? MgV MgV 2 O 4 4 a=0.843nm a=0.843nm

EXAFS of standard phases EXAFS of standard phases EXAFS of standard phases EXAFS of standard phases XANES of the V K XANES of the V K- XANES of the V K XANES of the V K -edge edge edge edge V 2 O 3 (V 3+ ) Pure Mg 3 V 2 O 8 Looks like V 5+ in the unused and V 2 O 4 (V 4+ ) used state V 2 O 5 (V 5+ )

In In- -situ EXAFS of the 14V/VMgO catalyst situ EXAFS of the 14V/VMgO catalyst situ EXAFS of the 14V/VMgO catalyst In In situ EXAFS of the 14V/VMgO catalyst XANES of the V K XANES of the V K- XANES of the V K XANES of the V K -edge edge edge edge 14V/VMgO in air @ 500 o C 14V/VMgO in reaction mixture @ 500 o C Resembles V 5+ in the unused Resembles V 3+ in the used state state

In In- -situ electrical conductivity measurements on the situ electrical conductivity measurements on the situ electrical conductivity measurements on the In In situ electrical conductivity measurements on the 14V/VMgO catalyst 14V/VMgO catalyst 14V/VMgO catalyst 14V/VMgO catalyst Increased n-type conductivity observed on reduction

Recommend

More recommend