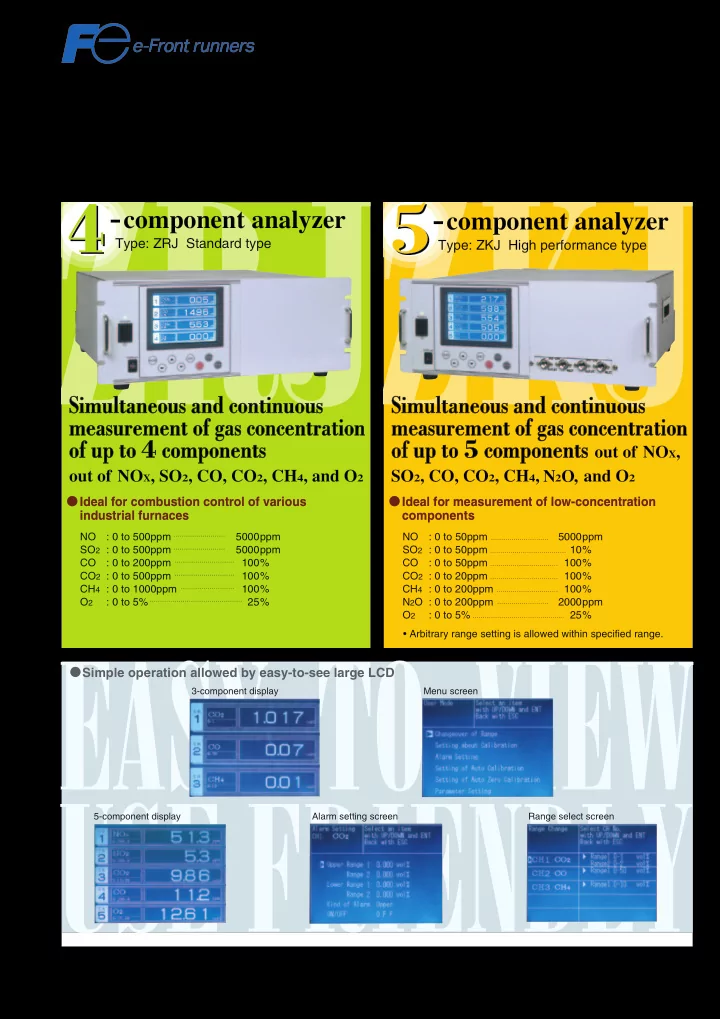

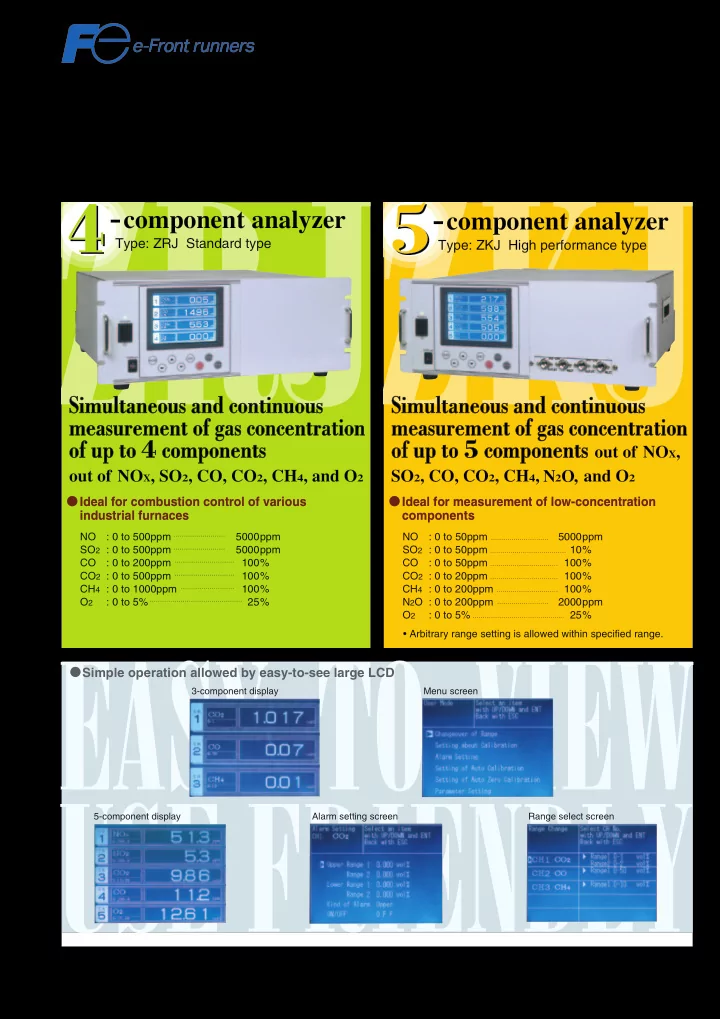

•Arbitraryrangesettingisallowedwithinspecifiedrange. Stand-alone type Infrared Gas Analyzer - component analyzer - component analyzer Type: ZRJ Standard type Type: ZKJ High performance type Ideal for combustion control of various Ideal for measurement of low-concentration industrial furnaces components NO : 0 to 500ppm 5000 ppm NO : 0 to 50ppm 5000 ppm SO 2 : 0 to 500ppm 5000 ppm SO 2 : 0 to 50ppm 10 % CO : 0 to 200ppm 100 % CO : 0 to 50ppm 100 % CO 2 : 0 to 500ppm 100 % CO 2 : 0 to 20ppm 100 % CH 4 : 0 to 1000ppm 100 % CH 4 : 0 to 200ppm 100 % O 2 : 0 to 5% 25 % N 2 O : 0 to 200ppm 2000 ppm O 2 : 0 to 5% 25 % Simple operation allowed by easy-to-see large LCD 3-component display Menu screen 5-component display Alarm setting screen Range select screen ECNO:325c

- component analyzer - component analyzer Type: ZRJ single-beam Hot wire temperature Principle The amount of infrared ray absorbed in the measurement cell is detected with a Bore: 1mm mass flow sensor. State of windlessness Infrared ray Gas inlet Gas outlet Rear expansion Mass flow sensor Detection light source chamber (Hot-wire wind speed sensitivity detecting element) ( ∆ P) ∆ <Mass flow sensor> When wind is The low impedance sensor has high noise blowing from left immunity. The sensor with no movable parts has high resistance to vibration, and Detection ∆ sensitivity thus can be used semipermanently. Front expansion Detector ( ∆ P) ∆ Motor chamber Measurement cell Infrared ray absorption by measured gas When wind is Mass flow sensor Chopper blowing from component is converted into electric right signals. ■ Zirconia type O 2 Sensor ■ Example of gas sampling system configuration (For measurement of ambient gas of heat treat furnace) Type : ZFK7 Flowmeter Clean air Sample gas Pump Cock inlet Exhaust Analyzer port Filter Membrane Pot ZRJ Filter filter Zero gas Span gas ■ General Specifications ■ External contact No voltage contact Measurement NOx, SO 2 , CO, CO 2 , CH 4 : input Auto calibration start, Average value reset, Range principle Non-dispersive infrared ray system (single-beam) selection, Output hold O 2 : Paramagnetic type (built in), galvanic cell type Contact output Range identification of each component, Instrument (built in), or zirconia type (Type ZFK7, Separately error, Calibration error, Auto calibration in progress, installed) CO peak count alarm, Instantaneous value Measured NO: 0 to 500ppm 5000ppm concentration alarm for each component, Pump component SO 2 : 0 to 500ppm 5000ppm ON/OFF CO: 0 to 200ppm 100% Communication RS-232C (MODBUS) option CO 2 : 0 to 500ppm 100% function CH 4 : 0 to 1000ppm 100% Auto calibration Auto zero and span calibration (Calibration cycle O 2 : 0 to 5% 25% function settable) (2-range switching, Maximum range ratio 1:5, O 2 Display LCD with backlight excluded) Instantaneous value of each component, Repeatability ± 0.5%FS Instantaneous value after O2 correction, Average Linearity ± 0.1%FS or lower value after O 2 correction, Average O 2 value, CO Zero drift ± 2.0%FS or lower/week peak count Span drift ± 2.0%FS or lower/week Parameter setting display (English or Japanese can Gas extraction 1L/min. ± 0.5L/min. be selected.) volume Outside dimension, 177 (H) × 483 (W) × 493 (D) mm, About 10kg Response time 90% response from gas inlet: 15 sec. or shorter weight (2-component measurement) Power supply voltage 100 to 240V AC, 50/60Hz, 70VA Output signal 4 to 20mA DC or 0 to 1V DC (Max. non-insulated output point: 8) ■ Standard measured gas conditions for gas analyzer ■ Instantaneous output value (measured gas concentration of each component) Temperature 0 to 50°C Instantaneous output value after O 2 correction, Pressure 10kPa or lower (The gas outlet should be at atmospheric pressure.) Average output value after O 2 correction, Average 100 μ g/Nm 3 or lower with particle size of 1 μ m or lower Dust μ μ O 2 output Mist No mist allowed. Permissible load resistance: 550 Ω or lower (4 to Moisture Saturated at 2°C (No condensation allowed.) 20mA DC), 100k Ω (0 to 1V DC) Ω Ω Corrosive component 1ppm or lower

- component analyzer Type: ZKJ double-beam Hot wire temperature Principle The amount of infrared ray absorbed in the measurement cell is detected Bore: 1mm with a mass flow sensor. State of windlessness Distribution cell (interference filter) Mass flow Mass flow sensor (Hot-wire wind sensor Detection speed detecting element) Motor Reference cell Trimmer sensitivity ( ∆ P) <Mass flow sensor> When wind is The low impedance sensor has high noise P Rotary Detector blowing from sector immunity. The sensor with no movable left P- ∆ P parts has high resistance to vibration, and Detection thus can be used semipermanently. sensitivity Infrared ray absorption by measured gas ( ∆ P) Infrared (single) component is converted into electric When wind is Sample gas Interference Sample gas outlet light source blowing from signals. Maximum range ratio of 1:25 is inlet compensationg right Sample cell detector allowed with the high sensitivity analyzer. ■ Zirconia type O 2 Sensor Example of gas sampling system configuration (For measurement of exhaust gas from boilers and refuse incinerators) Type : ZFK7 Gas extractor ZKJ Membrane Gas inlet filter Flowmeter Mist filter CO,CO 2 tube (O 2 ) Gas aspirator 15°or larger Infrared NO 2 /NO converter Membrane gas (for NOx measurement) filter analyzer Electronic gas cooler Solenoid valve NO,SO 2 ZERO NO SO 2 CO 2 CO O 2 Safety drain trap Pressure reducing valve O 2 Gas outlet Zirconia O 2 sensor Standard gas Drain ■ General Specifications External contact No voltage contact Measurement NOx, SO 2 , CO, CO 2 , CH 4 : input Auto calibration start, Average value reset, Range principle Non-dispersive infrared ray system (Double-beam) selection, Output hold, Pump ON/OFF O 2 : Paramagnetic type (built in) or zirconia type Contact output Range identification of each component, Instrument (Type ZFK7, Separately installed) error, Calibration error, Auto calibration in progress, Measured NO: 0 to 50ppm 5000ppm Pump ON/OFF, CO peak count alarm, Instantaneous component SO 2 : 0 to 50ppm 10% value concentration alarm for each component, CO: 0 to 50ppm 100% Power OFF CO 2 : 0 to 20ppm 100% Communication RS-232C (MODBUS) option CH 4 : 0 to 200ppm 100% function N 2 O: 0 to 200ppm 2000ppm Auto calibration Auto zero and span calibration (Calibration cycle O 2 : 0 to 5% 25% function settable) (2-range switching, Maximum range ratio 1:5, O 2 Display LCD with backlight excluded) Instantaneous value of each component, Repeatability ± 0.5%FS ( ± 1%FS for concentration of less than 50ppm) Instantaneous value after O 2 correction, Average Linearity ± 1.0%FS or lower value after O 2 correction, Average O 2 value, CO Zero drift ± 1.0%FS or lower/week peak count ( ± 2.0%FS/week for concentration from 50ppm to 200ppm) Parameter setting display (English or Japanese can Span drift ± 2.0%FS or lower/week be selected.) ( ± 2.0%FS/day for concentration of less than 50ppm) Outside dimension, 177 (H) × 483 (W) × 578 (D) mm, About 22kg Gas extraction volume 0.5L/min. ± 0.2L/min. weight Response time 90% response from gas inlet: 60 sec. or shorter Power supply voltage 100 to 240V AC, 50/60Hz, 250VA Output signal 4 to 20mA DC or 0 to 1V DC (Max. non-insulated output point: 12) ■ Standard measured gas conditions for gas analyzer Instantaneous output value (measured gas concentration of each component) Temperature 0 to 50°C Instantaneous output value after O 2 correction, Pressure 10kPa or lower (The gas outlet should be at atmospheric pressure.) Average output value after O 2 correction, Average 100 μ g/Nm 3 or lower with particle size of 1 μ m or lower Dust O 2 output Mist No mist allowed. Permissible load resistance: Moisture Saturated at 2°C (No condensation allowed.) 550 Ω or lower (4 to 20mA DC), 100k Ω (0 to 1V DC) Corrosive component 1ppm or lower

■ Outline Diagram (Unit mm) ■ Type : ZRJ <Upper> <Side> 500 max 355.6 365 336.5 254 123.8 111.1 101.5 (24) 38 88.5 M4 (for slide rail) <Front> <Rear> Purge gas inlet Rc1/4 or NPT1/4 Sample gas outlet Rc1/4 or NPT1/4 Power switch <Rack mount hole pitch> 429 M5 Sample gas inlet Rc1/4 or NPT1/4 7.5 100.8 169 177 194 Applicable both for JIS 100 mm and EiA 101.6 mm 465 AC inlet (100V to 240V AC, 50Hz/60Hz) Terminal Terminal Terminal block 1 block 3 block 5 483 Rubber boss for installing on a table or the like Terminal Terminal block 2 block 4 ■ Type : ZKJ <Side> <Upper> M4(for mounting slide rail) 578 or less 315.8 466.7 288.9 12.7 123.8 (22) 38 26.1 <Front> <Rear> 429 Power switch Sample gas outlet Rc1/4 or NPT1/4 Sample gas inlet Rc1/4 or NPT1/4 7.5 100.8 (Purge gas inlet Rc1/4 or NPT1/4) 177 169 465 Connector for input/output Power inlet (100V to 240V AC, 50Hz/60Hz) terminal module 483 International Sales Div. Sales Group Gate City Ohsaki, East Tower, 11-2, Osaki 1-chome, Shinagawa-ku, Tokyo 141-0032, Japan http://www.fujielectric.com Phone: 81-3-5435-7280, 7281 Fax: 81-3-5435-7425 http://www.fujielectric.com/products/instruments/ Information in this catalog is subject to change without notice. Printed in Japan 2011-4/20FOLS

Recommend

More recommend