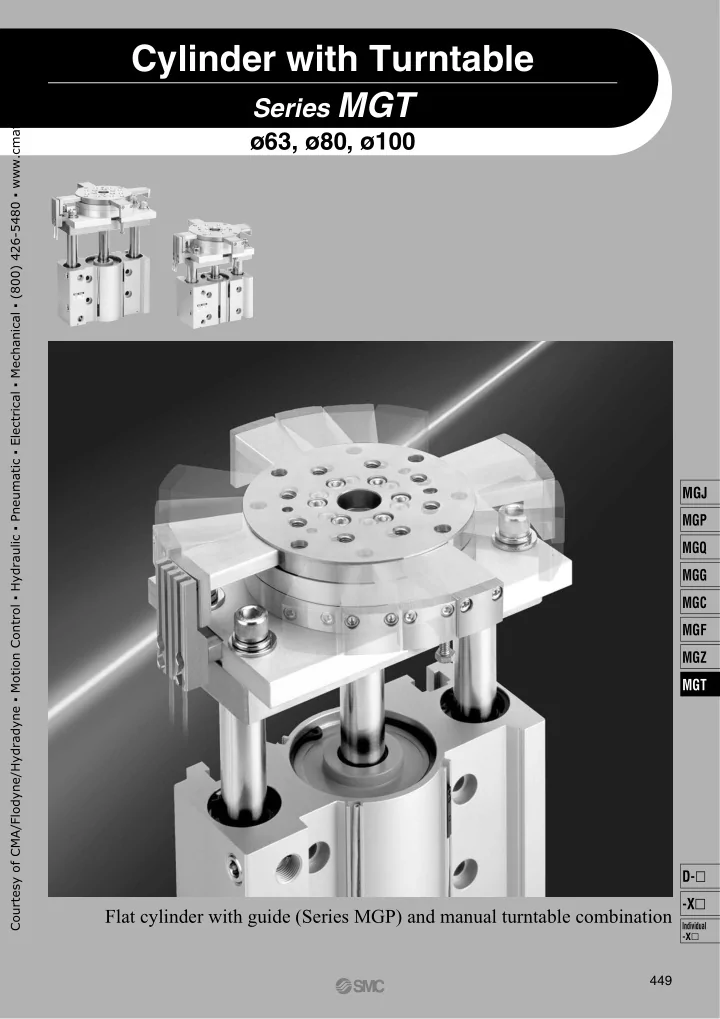

Cylinder with Turntable Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com Series MGT ø63, ø80, ø100 MGJ MGP MGQ MGG MGC MGF MGZ MGT D- � -X � Flat cylinder with guide (Series MGP) and manual turntable combination Individual -X � 449

Cylinder with Turntable Series MGT Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com ø63, ø80, ø100 Flat cylinder with guide (Series MGP) and manual turntable combination High precision bearings for smooth turning return movement Table unit has positioning mechanisms for each 90 ° and 180 ° of rotation 180 ° 9 0 ° Rotation position is detected by provision of an auto switch sensor Can be mounted 3 ways Side mounting Front mounting Side piping Front piping Bottom mounting Bottom mounting Application Example Assembly lines, inspection lines etc. Front mounting Side mounting with turning operations Series Variations Bearing Bore size Model Standard stroke (mm) type (mm) Slide MGTM 63 bearing 25, 50, 75, 100, 125, 150, 175, 200 80 Ball MGTL bushing 100 bearing 450

Cylinder with Turntable Series MGT Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com ø63, ø80, ø100 How to Order MGT M 63 50 11 M9BW M9BW 4 Cylinder unit/ Cylinder with Turntable Table unit/ Number of Number of auto switches Guide rod bearing type auto switches Nil 2 pcs. Cylinder unit/ S 1 pc. M Slide bearing S 1 pc. Auto switch 2 2 pcs. L Ball bushing bearing 3 3 pcs. Without auto switch Nil Bore size (Built-in magnet) 4 4 pcs. 63 63 mm ∗ For the applicable auto switch Port thread type model, refer to the table below. 80 80 mm Nil Rc 100 100 mm Table position detector hardware TN NPT TF G Positioning Switch Position detector arms Symbol Table unit/ c angle bracket a b c d Auto switch 10 11 Stroke (mm) Without auto switch Nil 12 (Built-in magnet) 90 ° Refer to “Standard 13 MGJ Stroke” on page ∗ For the applicable auto switch d b 14 Table position 452. model, refer to the table below. 15 detector arm MGP 20 a 23 180 ° Auto switch mounting bracket 25 MGQ Cylinder Unit/Applicable Auto Switch /Refer to pages 1719 to 1827 for detailed specifications of auto switches. MGG Indicator Load voltage Auto switch model Lead wire length (m) Pre-wired Special Electrical Wiring Applicable light Type 0.5 1 3 5 function entry (Output) connector load DC AC Perpendicular In-line MGC (Nil) (M) (L) (Z) 3-wire � � � � � M9NV M9N (NPN) 5 V, IC MGF 12 V circuit 3-wire Solid state switch M9P � � � � � — M9PV (PNP) ∗ Lead wire length symbols: 2-wire 12 V � � � � � M9BV M9B — MGZ Relay, 0.5 m ··········· Nil (Example) M9NW Grommet Yes 24V — 3-wire 1 m ··········· M (Example) M9NWM PLC M9NWV M9NW � � � � � Diagnostic (NPN) 5 V, IC 3 m ··········· L (Example) M9NWL MGT indication 12 V circuit 5 m ··········· Z (Example) M9NWZ 3-wire M9PWV M9PW � � � � � (PNP) (2-color indication) ∗ Refer to page 457 for applicable 2-wire 12 V M9BWV M9BW � � � � � — auto switches other than listed 3-wire IC above. — 5 V — A96V � � — A96 — — — circuit ∗ Refer to pages 1784 and 1785 for (NPN equiv.) switch Yes Reed details of auto switches with a pre- — Grommet 100 V A93V A93 � — � — — — wired connector. Relay, 2-wire 24V 12 V ∗ Auto switches are shipped 100 V IC PLC No � � A90V A90 — — — together (not assembled). or less circuit ∗ Solid state auto switches marked “ � ” are produced upon receipt of order. Table Unit/Applicable Auto Switch /Refer to pages 1719 to 1827 for detailed specifications of auto switches. Indicator Load voltage Auto switch model Lead wire length (m) Special Electrical Wiring Pre-wired Applicable light Type 0.5 1 3 5 function entry (Output) DC AC In-line connector load (Nil) (M) (L) (Z) 3-wire (NPN) M9N � � � � � IC circuit ∗ Lead wire length symbols: Solid state — 3-wire (PNP) M9P � � � � � switch 0.5 m ··········· Nil (Example) M9NW 2-wire M9B � � � � � Relay, D- � 1 m ··········· M (Example) M9NWM Grommet Yes 24V 12 V — 3-wire (NPN) M9NW � � � � � PLC Diagnostic IC 3 m ··········· L (Example) M9NWL indication circuit 5 m ··········· Z (Example) M9NWZ 3-wire (PNP) M9PW � � � � � (2-color -X � 2-wire — indication) M9BW � � � � � ∗ Refer to pages 1784 and 1785 for 3-wire (NPN equiv.) — 5 V — A96 � — � — — IC circuit — switch Reed details of auto switches with a pre- Yes Individual — Grommet 100 V A93 � — � — — — Relay, wired connector. -X � 2-wire 24V 12 V ∗ Auto switches are shipped No 100 V or less A90 � — � — — IC circuit PLC together (not assembled). ∗ Solid state auto switches marked “ � ” are produced upon receipt of order. ∗ The in-line electrical entry type cannot be mounted. 451

Series MGT Courtesy of CMA/Flodyne/Hydradyne ▪ Motion Control ▪ Hydraulic ▪ Pneumatic ▪ Electrical ▪ Mechanical ▪ (800) 426-5480 ▪ www.cmafh.com Specifications 63 80 100 Bore size (mm) Action Double acting Fluid Air Proof pressure 1.5 MPa Maximum operating pressure 1.0 MPa Minimum operating pressure 0.1 MPa Ambient & fluid temperatures –10 to 60 ° C (No freezing) Piston speed 50 to 400 mm/s Cushion Rubber bumper on both ends Lubrication Non-lube +1.5 Stroke length tolerance mm 0 Table rotation system Manual type Table rotation direction Right, left, free repetetive rotation Quarter circle 90 ° , half circle 180 ° , Table angle of rotation with positioning mechanism Standard Stroke Theoretical Output Bore size (mm) Standard strokes (mm) OUT (N) IN (N) 63 25, 50, 75, 100, 125, (N) 80 150, 175, 200 Piston Operating pressure (MPa) Bore size Rod size Actuation 100 area (mm) (mm) direction (mm 2 ) 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 Intermediate strokes OUT 3117 623 935 1247 1559 1870 2182 2494 2805 3117 Intermediate strokes (in 5 mm increments) other than the 63 20 standard stokes are made by installing spacers of 5, 10, 15 IN 2803 561 841 1121 1402 1682 1962 2242 2523 2803 and 20 mm widths. (Ex.) 1.MGTM63-35 st is made by installing a 15 mm OUT 5027 1005 1508 2011 2514 3016 3519 4022 4524 5027 spacer inside a MGTM63-50 st , however the overall 80 25 length will be the same as the 50 st . IN 4536 907 1361 1814 2268 2722 3175 3629 4082 4536 OUT 7854 1571 2356 3142 3927 4712 5498 6283 7069 7854 100 30 IN 7147 1429 2144 2859 3574 4288 5003 5718 6432 7147 Note) Theoretical output (N) = Pressure (MPa) x Piston area (mm 2 ) Additional Bracket Mass Mass (kg) Symbols for table unit position detector bracket MGTM63 to 100 (Slide bearing) (kg) Bore size 10 11 12 13 14 15 (mm) Standard stroke (mm) Bore size Model 20 — — 23 — 25 (mm) 25 50 75 100 125 150 175 200 63 0 0.21 0.16 0.12 0.12 0.08 6.96 7.81 8.57 9.32 10.08 10.83 11.59 13.10 63 MGTM63 (4.78) (5.12) (5.38) (5.63) (5.88) (6.14) (6.39) (6.90) 80 0 0.24 0.19 0.14 0.13 0.08 12.07 13.31 14.25 15.18 16.12 17.06 18.00 19.87 80 MGTM80 (9.29) (9.96) (10.33) (10.71) (11.08) (11.46) (11.83) (12.58) 100 0 0.25 0.19 0.14 0.14 0.09 (17.83) (19.56) 20.89 22.22 23.55 24.88 26.21 28.87 100 MGTM100 (13.51) (14.45) (14.99) (15.53) (16.07) (16.60) (17.14) (18.22) MGTL63 to 100 (Ball bushing bearing) (kg) Standard stroke (mm) Bore size Model (mm) 25 50 75 100 125 150 175 200 6.62 7.49 8.15 8.91 9.57 10.24 10.90 12.23 63 MGTL63 (4.33) (4.61) (4.80) (5.08) (5.27) (5.45) (5.64) (6.01) 12.03 13.33 14.15 14.97 15.79 16.61 17.43 19.07 80 MGTL80 (8.92) (9.44) (9.73) (10.02) (10.31) (10.60) (10.89) (11.46) 17.53 19.33 20.51 21.69 22.87 24.04 25.22 27.58 100 MGTL100 (12.84) (13.62) (14.04) (14.46) (14.87) (15.29) (15.70) (16.54) Numbers inside ( ) indicate the mass of moving parts. 452

Recommend

More recommend