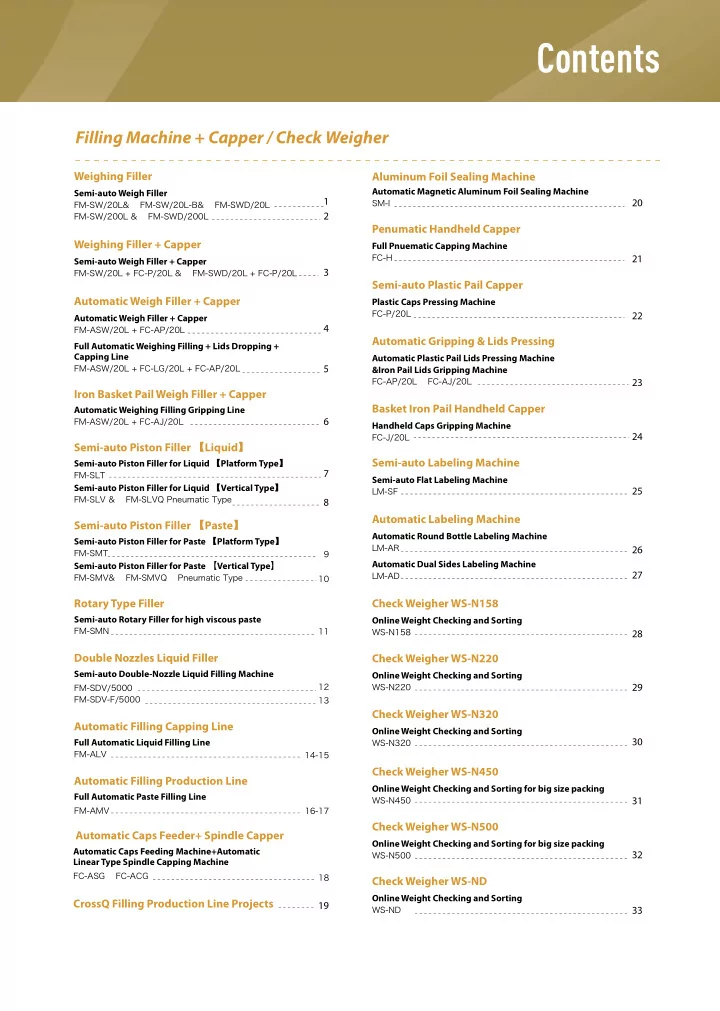

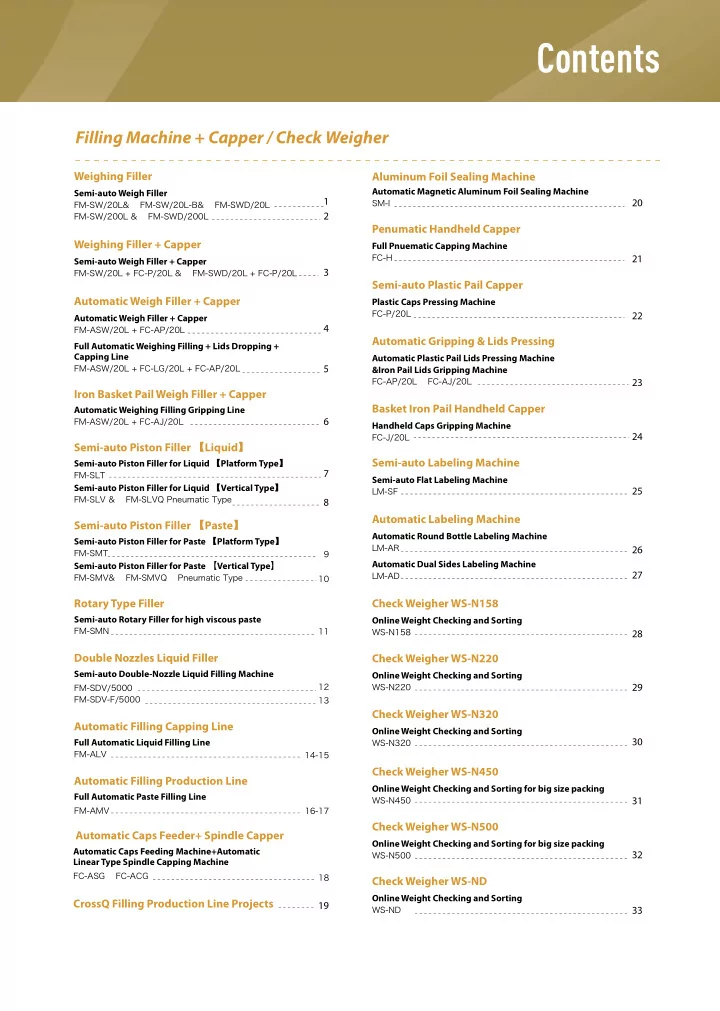

5 FM-SLV � FM-SLVQ Pneumatic Type WS-N220 WS-N320 WS-N450 WS-N500 LM-AR LM-AD FM-SW/20L + FC-P/20L � FM-SWD/20L + FC-P/20L FM-ASW/20L + FC-AP/20L FM-ASW/20L + FC-LG/20L + FC-AP/20L FM-ASW/20L + FC-AJ/20L 9 10 FM-SLT FM-SMT LM-SF FM-SMV� FM-SMVQ Pneumatic Type 11 FM-SMN 12 13 FM-SDV/5000 FM-SDV-F/5000 14-15 FM-ALV 16-17 FM-AMV 18 FC-ASG FC-ACG WS-N158 WS-ND FC-J/20L FC-AP/20L FC-AJ/20L FM-SW/20L� FM-SW/20L-B� FM-SWD/20L FM-SW/200L � FM-SWD/200L SM-I FC-H FC-P/20L Contents Filling Machine + Capper / Check Weigher Weighing Filler Aluminum Foil Sealing Machine Automatic Magnetic Aluminum Foil Sealing Machine Semi-auto Weigh Filler 1 20 2 Penumatic Handheld Capper Weighing Filler + Capper Full Pnuematic Capping Machine 21 Semi-auto Weigh Filler + Capper 3 Semi-auto Plastic Pail Capper Automatic Weigh Filler + Capper Plastic Caps Pressing Machine 22 Automatic Weigh Filler + Capper 4 Automatic Gripping & Lids Pressing Full Automatic Weighing Filling + Lids Dropping + Capping Line Automatic Plastic Pail Lids Pressing Machine 5 &Iron Pail Lids Gripping Machine 23 Iron Basket Pail Weigh Filler + Capper Basket Iron Pail Handheld Capper Automatic Weighing Filling Gripping Line 6 Handheld Caps Gripping Machine 24 Semi-auto Piston Filler 【 Liquid 】 Semi-auto Labeling Machine Semi-auto Piston Filler for Liquid 【 Platform Type 】 7 Semi-auto Flat Labeling Machine Semi-auto Piston Filler for Liquid 【 Vertical Type 】 25 8 Automatic Labeling Machine Semi-auto Piston Filler 【 Paste 】 Automatic Round Bottle Labeling Machine Semi-auto Piston Filler for Paste 【 Platform Type 】 26 Automatic Dual Sides Labeling Machine Semi-auto Piston Filler for Paste 【 Vertical Type 】 27 Rotary Type Filler Check Weigher WS-N158 Semi-auto Rotary Filler for high viscous paste Online Weight Checking and Sorting 28 Double Nozzles Liquid Filler Check Weigher WS-N220 Semi-auto Double-Nozzle Liquid Filling Machine Online Weight Checking and Sorting 29 Check Weigher WS-N320 Automatic Filling Capping Line Online Weight Checking and Sorting 30 Full Automatic Liquid Filling Line Check Weigher WS-N450 Automatic Filling Production Line Online Weight Checking and Sorting for big size packing Full Automatic Paste Filling Line 31 Check Weigher WS-N500 Automatic Caps Feeder+ Spindle Capper Online Weight Checking and Sorting for big size packing Automatic Caps Feeding Machine+Automatic 32 Linear Type Spindle Capping Machine Check Weigher WS-ND Online Weight Checking and Sorting CrossQ Filling Production Line Projects 19 33

1 Semi-auto Weigh Filler 22 FM-SWD/20L 【Double Nozzles】 【Full SUS Type】 FM-SW/20L LCD touch screen】 FM-SW/20L-B 【Single Nozzle with FM-SW/20L【Single Nozzle】 Weighing Filler FM-SW/20L& FM-SW/20L-B& FM-SWD/20L APPLICATION Weighing fjlling machine is made based on international technique, with fjlling and electronic weigh, electronic displaying functions. It is suitable for medium bucket fjlling of various kinds of viscous, non- viscous, corrosive and non-corrosive liquid. TECHNICAL PARAMETER FEATURE 01.Filling Method: Filling from top. FM-SW/20L-B FM-SW/20L FM-SWD/20L 02.Control Mode: Manual setting fjlling way, micro Name (Single Nozzle with LCD (Single Nozzle) (Double Nozzles) switch control. Touch Screen) 03.Conveying Mode: Roller Type Conveying without Filling Range 5-30kg 5-30kg engine. Filling Speed 120-150pails/hour 240-300pails/hour 04.Own digital displaying fjlling quantity function, Filling Accuracy ±0.2% can fjnish multi-kinds fjlling quantity setting. 05.Automatic peeled, based on net weight fjlling In-feed Pressure 0.3~0.35MPa function. Working Pressure 0.4~0.6MPa 06.Own vacuum withdrawing function to avoid 3 /min Air Supply 0.2m anti-drip. 07.With manual & automatic micro switch control Powder AC220V 50HZ system function. Dimension ( mm ) 1000x650x1450 1500x650x1450 08.Dual speed control function to prevent Weight 95 kg 160 kg splashing. 09. With emergent treatment to avoid misuse and protect power-ofg. • Above is standard data, difgerent products and viscosity may efgect above data. • Each CrossQ equipment can be done with full stainless steel (SUS304) structure. 10. With SUS316 material of inside pipeline, which is • FM-SWD/20L-B: Double Nozzles LCD Touch screen type, can be order at CrossQ company. liquid contact part. • Pails In-feeding & Out-feeding roller: length can be optional at CrossQ company.

2 Semi-auto Weigh Filler Weighing Filler FM-SW/200L & FM-SWD/200L FM-SW/200L 【 Single Nozzle 】 APPLICATION Weighing fjlling machine is made based on international technique, with fjlling and electronic weigh, electronic displaying functions. It is suitable for medium and big bucket fjlling of various kinds of viscous, non-viscous, corrosive and non-corrosive liquid. FM-SWD/200L 【 Double Nozzles 】 FEATURE TECHNICAL PARAMETER 01. Filling Method: Filling from top. FM-SW/200L FM-SWD/200L Model (Single Nozzle) (Double Nozzles) 02. Control Mode: Manual setting fjlling way, micro Filling Range 20-300kg 20-300kg switch control. 03. Conveying Mode: Roller Type Conveying Filling Speed 40-60 barrels/hour 80-120barrels/hour without engine. Filling Accuracy ±0.1% 04. Own digital displaying fjlling quantity function, In-feed Pressure 0.3~0.35MPa can fjnish multi-kinds fjlling quantity setting. Working Pressure 0.4~0.6MPa 05. Automatic peeled, based on net weight fjlling 3 /min Air Supply 0.2m function. Power Supply AC220V 50HZ 06. Own vacuum withdrawing function to avoid Dimension (mm) 1200x870x1650 (mm) 1500x870x1650 (mm) anti-drip. Weight 120 kg 200 kg 07. With manual & automatic micro switch control system function. • Above is standard data, difgerent products and viscosity may efgect above data. • Each CrossQ equipment can be done with full stainless steel (SUS304) structure. 08. Dual speed control function to prevent • FM-SWD/200L-B & FM-SWD/200L-B: Double Nozzles LCD Touch screen type, can be order at CrossQ company. splashing. • Barrels In-feeding & Out-feeding roller: length can be optional at CrossQ company. 09. With emergent treatment to avoid misuse and protect power-ofg. 10. With SUS316 material of inside pipeline, which is liquid contact part.

3 Semi-auto Weigh Filler + Capper Weighing Filler + Capper FM-SW/20L + FC-P/20L & FM-SWD/20L + FC-P/20L FM-SW/20L + FC-P/20L FM-SW/20L-B + FC-P/20L APPLICATION Weighing fjlling machine is made based on international technique, with fjlling and electronic weigh, electronic displaying functions. It is suitable for medium bucket fjlling of various kinds of viscous, non- viscous, corrosive and non-corrosive liquid. FM-SW/20L 【 SUS 】 + FC-P/20L FM-SWD/20L + FC-P/20L TECHNICAL PARAMETER FEATURE 01. Filling Method: Filling from top. Single Nozzle Filler Double Nozzles Filler Name 02. Control Mode: Manual setting fjlling way, micro + Plastic Capper + Plastic Capper switch control. Model FM-SW/20L + FC-P/20L FM-SWD/20L + FC-P/20L 03. Conveying Mode: Roller Typ Conveying without Control System Electronic-Pneumatic engine. Filling Range 5-30kg 5-30kg 04. Own digital displaying fjlling quantity function, can fjnish multi kinds fjlling quantitysetting. Capping Head Size ¢ 340mm (Optional) 05. Automatic peeled, based on net weight fjlling Filling Speed 120-150pails/hour 240-300pails/hour function. Filling Accuracy ±0.2% 06. Own vacuum withdrawing function to avoid anti-drip. In-feed Pressure 0.3~0.35MPa 07. With manual & automatic micro switch control Working Pressure 0.4~0.6MPa system function. 3 /min Air Supply 0.2m 08. Dual speed control function to prevent splashing. Powder AC220V 50HZ 09. With emergent treatment to avoid misuse and Dimension 2000x650x1450 2500x650x1450 protect power ofg. Weight 95 kg + 100kg 160 kg + 100kg 10. With SUS316 material of inside pipeline, which is liquid contact part. • Above is standard data, difgerent products and viscosity may efgect above data. • Each CrossQ equipment can be done with full stainless steel (SUS304) structure. • FM-SW/20L-B + FC-P: Single Nozzle LCD Touch screen type + Plastic Capper • FM-SW/20L-B + FC-P: Double Nozzles LCD Touch screen type + Plastic Capper can be order at CrossQ company. • FC-J/20L Semi-auto Iron Pail Capping Machine: welcome to order at CrossQ company. • Pails In-feeding & Out-feeding roller: length can be optional at CrossQ company.

Recommend

More recommend