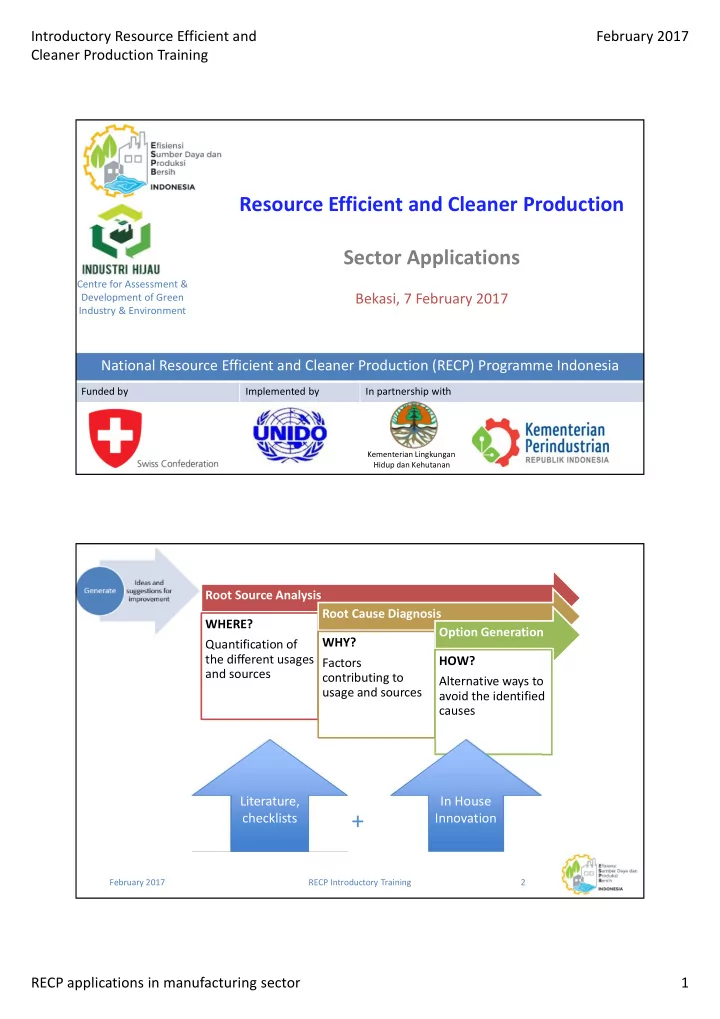

Introductory Resource Efficient and February 2017 Cleaner Production Training Resource Efficient and Cleaner Production Sector Applications Centre for Assessment & Development of Green Bekasi, 7 February 2017 Industry & Environment National Resource Efficient and Cleaner Production (RECP) Programme Indonesia Funded by Implemented by In partnership with Kementerian Lingkungan February 2017 RECP Introductory Training 1 Hidup dan Kehutanan Root Source Analysis Root Cause Diagnosis WHERE? Option Generation WHY? Quantification of the different usages HOW? Factors and sources contributing to Alternative ways to usage and sources avoid the identified causes Literature, In House + checklists Innovation February 2017 RECP Introductory Training 2 RECP applications in manufacturing sector 1

Introductory Resource Efficient and February 2017 Cleaner Production Training RECP for green industry Glass Industry Efisiensi Sumber Daya dan Produksi Bersih Metal Ceramic Products Industry Industry February 2017 RECP Introductory Training 3 Glass industry is energy and resource intensive sector. Diverse set of measures available to improve productivity and energy efficiency, and reduce waste and emissions (GHG, NOx). February 2017 RECP Introductory Training 4 RECP applications in manufacturing sector 2

Introductory Resource Efficient and February 2017 Cleaner Production Training Glass Industry in Gujarat (India) 1. Optimize combustion efficiency of furnace • Target 2-6% O 2 , 8-11% CO 2 , <400ppm CO and minimum excess air • Measure O 2 and regulate air flow (VFD on fan) • Investments typically 30-45,000 USD (up to 100 tpd) • Payback period typically 3-8 months February 2017 February 2017 RECP Introductory Training 5 GCPC (2016), Cleaner Production in Glass Sector Glass Industry in Gujarat (India) 2. Electricity savings • Variable Speed Drives on large motors (blowers) – Investment USD1-4,000 – Pay back 2-9 months • Optimize compressed air usage – Eliminate unnecessary use and leaks – Reduce pressure variations – Efficient compressors – Reduce air inlet temperature (3 o C decrease saves 1% energy) February 2017 February 2017 RECP Introductory Training 6 GCPC (2016), Cleaner Production in Glass Sector RECP applications in manufacturing sector 3

Introductory Resource Efficient and February 2017 Cleaner Production Training Glass Industry in Gujarat (India) 3. Oxygen Enhanced Combustion – Better glass quality, lower emissions (NO x and PM), higher throughput, energy savings (10-50%) and no air-preheating – Investments 180-300,000 USD – Pay back 18-30 months 4. Batch and Cullet Preheating – Direct or indirect – 10-20% reduction of specific energy consumption – 10-15% increase in throughput – Investments 75-225,000 USD – Pay back 28-34 months February 2017 RECP Introductory Training 7 GCPC (2016), Cleaner Production in Glass Sector Energy Use in Glass Industry • Over the past twenty years, glass demand has grown more quickly than GDP and is still growing at nearly 4% per year. • About 0.5-0.8 EJ of energy is used for glass production worldwide, and the energy used in the production of container and flat glass results in emissions of about 50-60 Mt CO 2 per year. • With the adoption of best available technologies, energy efficiency of the sector can be improved by as much as 40% in developing countries and up to 35% in industrialized ones. http://www.iipnetwork.org/ February 2017 RECP Introductory Training 8 February 2017 RECP applications in manufacturing sector 4

Introductory Resource Efficient and February 2017 Cleaner Production Training Energy Benchmarks Furnace Energy Consumption Overall Energy Consumption Sector Furnace Type/Capacity (GJ/tonne melted glass) (GJ/tonne finished product) Container Glass <100 t/d 5.5 – 7 Bottles & Jars >100 t/d 3.3 – 4.6 <7.7 Electric furnaces 2.9 – 3.6 <100 t/d 7 – 9 Flacconage <16 >100 t/d 4.8 – 6 Flat Glass All capacities 5 – 7 <8 Continous filament glass fibre All capacities 7 –14 <20 Domestic glass Conventional furnaces <100 t/d a 6.7 – 9.5 < 24 for capacities < 100 t/d a < 18 for capacities > 100 t/d >100 t/d 5 – 6 Electric furnaces b 3.4 – 4.3 Special glass All products Electric furnaces b 3.9 – 4.5 Soda-lime glas 5 – 10 20 < Conventional furnaces Borosilicate glass 10 – 15 http://www.iipnetwork.org/ February 2017 RECP Introductory Training 9 February 2017 Best Available Techniques http://www.iipnetwork.org/ RECP Introductory Training 10 February 2017 RECP applications in manufacturing sector 5

Introductory Resource Efficient and February 2017 Cleaner Production Training Process-Related Energy Efficiency Worell e.a (2008), Energy Efficiency Improvement February 2017 February 2017 RECP Introductory Training 11 and Cost Savings Opportunities in Glass Industry Process-Related Energy Efficiency Worell e.a (2008), Energy Efficiency Improvement February 2017 February 2017 RECP Introductory Training 12 and Cost Savings Opportunities in Glass Industry RECP applications in manufacturing sector 6

Introductory Resource Efficient and February 2017 Cleaner Production Training Process-Related Energy Efficiency Worell e.a (2008), Energy Efficiency Improvement February 2017 February 2017 RECP Introductory Training 13 and Cost Savings Opportunities in Glass Industry Cross Cutting Energy Efficiency • Energy Management Systems (ISO 50001) • Compressed Air Systems • Motor Systems • Lighting • Heat and Steam Systems • Building Management, including HVAC Worell e.a (2008), Energy Efficiency Improvement February 2017 RECP Introductory Training 14 and Cost Savings Opportunities in Glass Industry RECP applications in manufacturing sector 7

Introductory Resource Efficient and February 2017 Cleaner Production Training Ceramics sector produces variety of products (bricks, tableware, sanitary ware, tiles etc.). Energy and resource use are high, as are air emissions and waste generation. February 2017 RECP Introductory Training 15 Nguon Sam Ath Brick Company (Cambodia) February 2017 RECP Introductory Training 16 RECP applications in manufacturing sector 8

Introductory Resource Efficient and February 2017 Cleaner Production Training Angkor Brick Kiln (Cambodia) February 2017 RECP Introductory Training 17 Ceramics Industry in Gujarat (India) 1. Optimize combustion efficiency of furnace • Target 2-6% O 2 , 8-11% CO 2 , <400ppm CO and minimum excess air • Measure O 2 and regulate air flow (VFD on fan) • Investments typically < 1,000USD • Annual cost savings up to ~USD65,000 February 2017 February 2017 RECP Introductory Training 18 GCPC (2016), Cleaner Production in Ceramic Sector RECP applications in manufacturing sector 9

Introductory Resource Efficient and February 2017 Cleaner Production Training Ceramics Industry in Gujarat (India) 2. Optimize combustion efficiency of spray dryer furnace • Installation of O 2 analyzers for 3 spray dryers » Invested ~USD110,000, pay back in 4 months • Solar greenhouse drying of coal » Reduce moisture from 30 to 5% » Investment of ~USD40,000 with pay back in 5 months February 2017 February 2017 RECP Introductory Training 19 GCPC (2016), Cleaner Production in Ceramic Sector Ceramics Industry in Gujarat (India) 3. Modifying kiln cars for efficient transfer of heat (reduction of mass) – Replace solid shelves with extruded shelves • Invested USD8-20,000, payback < 5 months – Use light weight filling materials • Invested ~USD4,500, payback < 5 months – Redesign spacers/holding racks • Invested ~USD3,600, with payback < 1 month February 2017 February 2017 RECP Introductory Training 20 GCPC (2016), Cleaner Production in Ceramic Sector RECP applications in manufacturing sector 10

Introductory Resource Efficient and February 2017 Cleaner Production Training Ceramics Industry in Gujarat (India) 4. 100% reuse of water and sludge in process (zero effluent discharge) • Material recovery and water conservation at very low cost 5. Electricity conservation • Power factor improvement with capacitators • Variable speed drive on ball mill motors • On-off timers and other controls • Reduce and optimize use of compressed air • Improvement in kiln wall insulation February 2017 February 2017 RECP Introductory Training 21 GCPC (2016), Cleaner Production in Ceramic Sector Metal products industries employ comparable processes to produce wide variety of components and products. Energy consumption is high in most processes, whilst chemicals’ use, generation of waste and effluents vary. Multiple common RECP approaches are well known and proven. February 2017 RECP Introductory Training 22 RECP applications in manufacturing sector 11

Recommend

More recommend