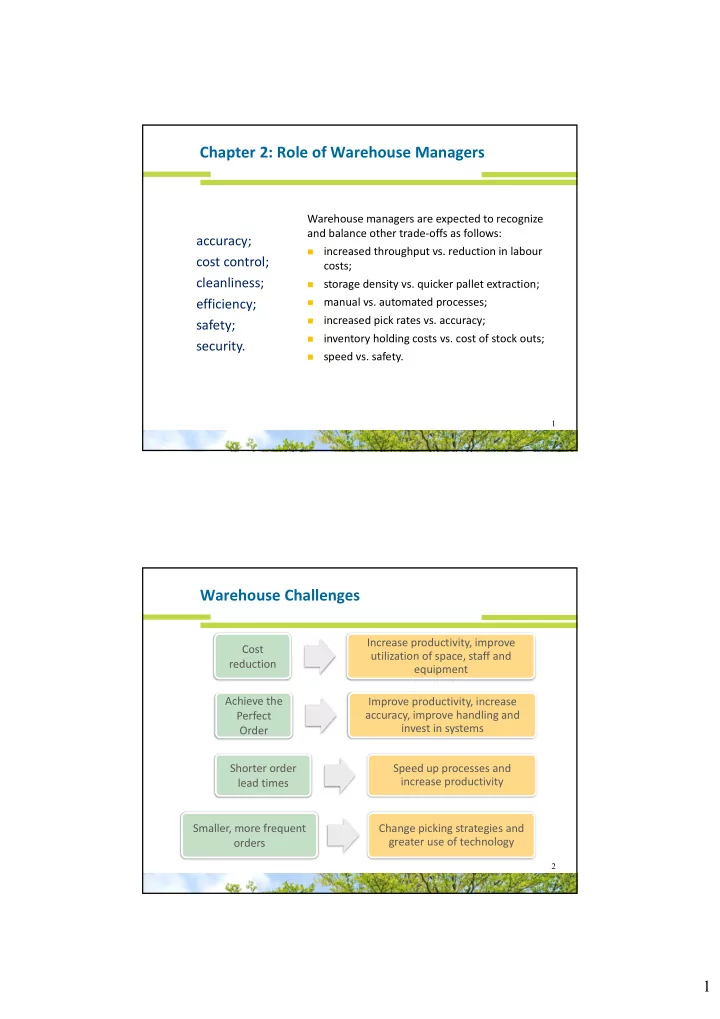

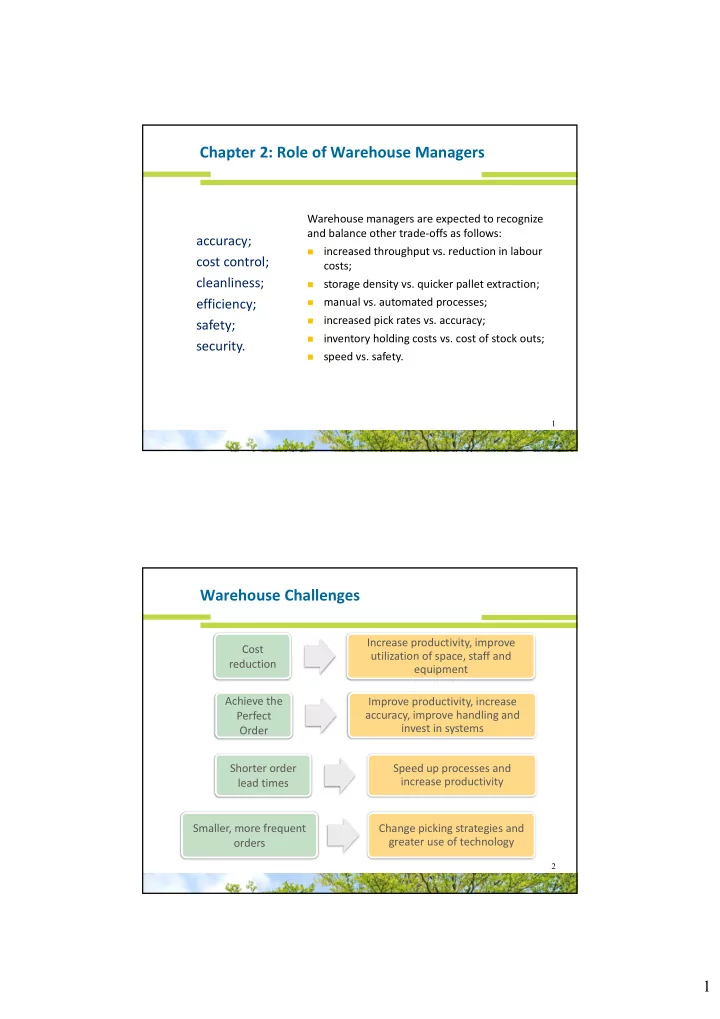

Chapter 2: Role of Warehouse Managers Warehouse managers are expected to recognize and balance other trade‐offs as follows: accuracy; increased throughput vs. reduction in labour cost control; costs; cleanliness; storage density vs. quicker pallet extraction; efficiency; manual vs. automated processes; increased pick rates vs. accuracy; safety; inventory holding costs vs. cost of stock outs; security. speed vs. safety. 1 Warehouse Challenges Increase productivity, improve Cost utilization of space, staff and reduction equipment Achieve the Improve productivity, increase accuracy, improve handling and Perfect invest in systems Order Shorter order Speed up processes and increase productivity lead times Smaller, more frequent Change picking strategies and greater use of technology orders 2 1

Warehouse Challenges Fluctuations Flexible working hours and improved forecasting in demand Increases in Postponement. Improved use of equipment such as carousels & flow racks SKUs Staff retention through excellent Labour cost and working conditions, flexible hours, availability training and improved productivity Environmental Manage energy more efficiently, better use of waste challenges Data accuracy and Introduce WMS and real‐time speed of transfer tracking & data transfer 3 Warehouse Cost Tree (Chapter 12) cost of errors? 4 2

Return On Investment (Chapter 6) A warehouse that picks 36,000 cases per day with a 99.8 % accuracy level incurs 72 errors per day. Increasing accuracy to 99.9 % reduces errors by 36 per day, or 10,800 per year. Assume that the cost of a picking error is £ 25, this can be an overall saving of £ 270,000. (p.141, p.160) ≈ 99.997 % in Japan 36,000 cases ÷ 7.5 hours /day ÷ 35 operators = 137 cases per hour. A 10 % productivity gain would raise the cases per hour to 151. × = 36,000 cases per day ÷ 7.5 hours per day ÷ 151 cases = 32 operators (p.145) 𝑆𝑃𝐽 � Gain savings from Investment − Investment � 100 Investment 5 What should We be Measuring? (Chapter 13) Reliability: on‐time delivery, fill rates, accuracy Flexibility: order cycle time Cost: cost as a percentage of sales, productivity against labour hours Asset utilization: effective use of space, equipment, and labour monitor performance against the criteria that are important to your customers (delivery of the perfect order); monitor performance against the criteria that are important to you (costs). 6 3

Traditional Productivity Measures Dock to stock time Stock cover in days Order cycle time 7 Different players have Different ideas as to What is important (Chapter 13) 8 4

The measures you choose need to be SMART. (Chapter 13) Specific Objectives should specify what they want to achieve. Are they clear and unambiguous? Measurable Can we put a value on the KPI? How much, how long, how many? Achievable Are the targets you set achievable and attainable? Relevant Are the measures relevant to the overall goal and strategy of the company? Timely Are the timescales realistic and how often do you measure? 9 New Performance Metrics (Chapter 13) On‐time delivery = 97% In full delivery = 98.5% Damage free = 99.5% Accurate documentation, labelling and invoicing = 98% Perfect Order Metric = 97% × 98.5% × 99.5% × 98% = 93.2% OTIF (on time and in full) = 97% × 98.5% = 95.5% 10 5

Lean Warehousing Seven Wastes or Muda transportation (driving an empty forklift) 空車行駛 defects (time spent correcting errors such as misspicks) 揀錯 inventories (congestion at the inbound and outbound areas) 進出貨區域擁擠 motion (interrupting movement such as staging product before put‐away) 入庫作業中斷 waiting time (bottlenecks at pick locations) 等候揀貨 overproduction (holding too much inventory) 庫存過多 overprocessing (performing unnecessary steps such as labelling and checking) 非必要的檢查 11 Examples half‐height and quarter‐height pallets taking up space in two‐ metre‐high locations; 零板佔用儲位 Solution: moving smaller pallets to other locations, reducing beam heights or adjustable heights part pallets of the same product spread over a number of different locations; 品項儲存於不同儲位 Solution: Consolidate the pallets. Tradeoff between labour cost and storage space. over 10 per cent of the stock was obsolete. 呆料庫存 Solution: Decisions have to be made in conjunction with the finance department to dispose of obsolete product 12 6

5S Sort or Seiri or Clear out Straighten or Seiton or Configure Shine or Seiso or Clean Standardize or Seiketsu or Conform Sustain or Shitsuke or Custom 13 Workforce Management identifying, attracting and retaining good supervisors, first line managers and team leaders; 基層幹部 retaining and attracting new employees; 員工流動率 an ageing and constantly changing workforce, including the introduction of foreign staff; 外勞 identifying training needs; 訓練 the need to provide safe, comfortable working conditions; 安全 employment contract negotiations; 勞動合約 compliance with employment and health and safety legislation 勞基法 staff discipline. 14 7

Attracting and Retaining Employees Many firms see monetary incentives as being key to staff recruitment and retention. Surveys suggests otherwise with active employee involvement in productivity improvement, … being seen as high on the list. (52) Flexible hours, recognition of a job well done, clean and safe working conditions, … crucial to attracting and retaining staff. (52) As warehouses become more technically advanced this will also attract a new breed of warehouse employee – those with an interest in technology and automation. 物流共和國 15 Warehouse Audit ISO 9001 – a standard of requirements against which your Quality Management System can be evaluated; 產品或作業品質 ISO 14001 – a standard of requirements that defines and establishes controls to reduce your company’s impact on the environment; 環保 ISO 50001 – a standard of requirements that deals with the energy impact of your warehouse operation; 節能 OHSAS 18001 (ISO 45001) – a standard of requirements against which your Health and Safety Management System can be evaluated; 職業健康安全 EICC Electronic Industry Citizenship Coalition 電子產業行為準則 ISO 27001 – a standard of requirements which deals with all aspects of information security (outsourced warehousing). 資訊安全 16 8

Summary Reducing cost and inventory whilst increasing customer service. Reducing waste An ageing population and difficulty in attracting new staff pose more challenges for today’s manager, together with increased environmental pressures. Quality of service is what sets companies apart. Warehouse audit checklists (p.387) 17 9

Recommend

More recommend