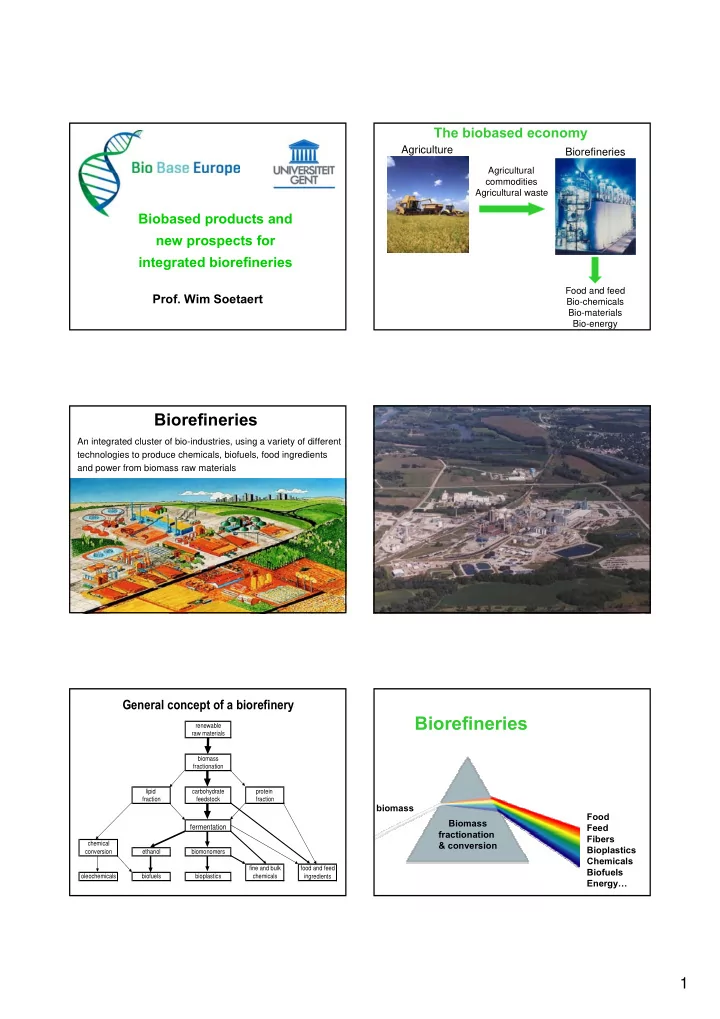

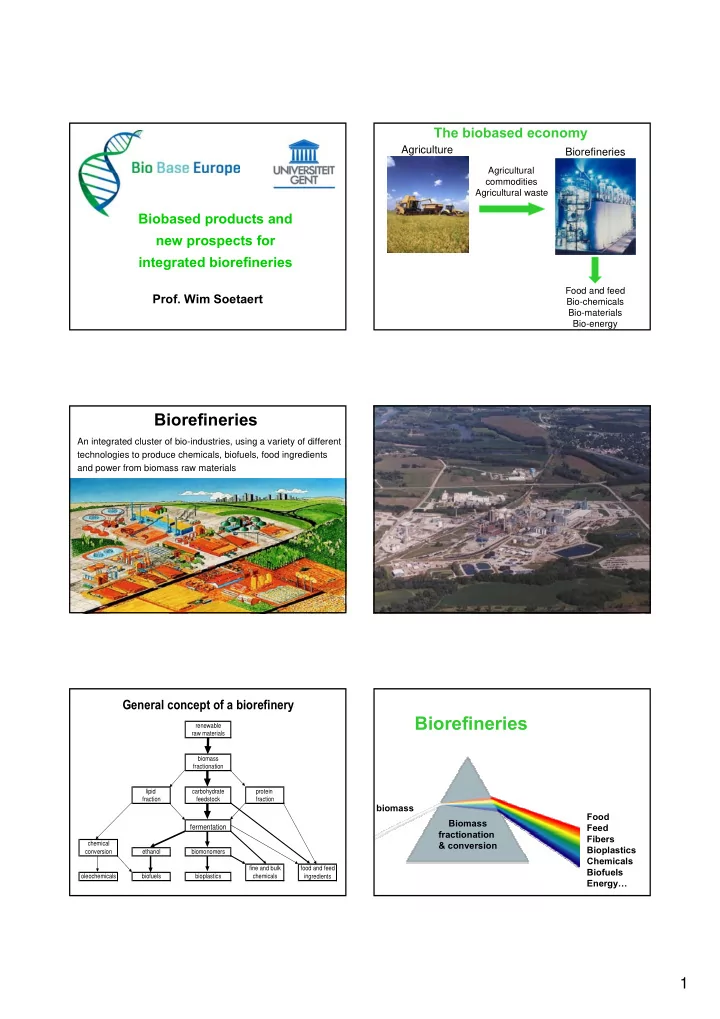

The biobased economy Agriculture Biorefineries Agricultural commodities Agricultural waste Biobased products and new prospects for integrated biorefineries Food and feed Prof. Wim Soetaert Bio-chemicals Bio-materials Bio-energy Biorefineries An integrated cluster of bio-industries, using a variety of different technologies to produce chemicals, biofuels, food ingredients and power from biomass raw materials Source: NREL General concept of a biorefinery Biorefineries renewable raw materials biomass fractionation lipid carbohydrate protein fraction feedstock fraction biomass Food Biomass Feed fermentation fractionation Fibers chemical & conversion Bioplastics conversion ethanol biomonomers Chemicals fine and bulk food and feed Biofuels oleochemicals biofuels bioplastics chemicals ingredients Energy… 1

Products of the biobased economy: In a biorefinery complex, a single raw material such as e.g. corn is converted into: • Food ingrediënts •Glucose food industry • Animal feed •Bio-ethanol bio-fuel • Fine chemicals •Bio-plastic (PLA) packaging • Bulk chemicals •Citric acid food additive • Biofuels •Starch carboxylate washing powder • Bioplastics •Antibiotics pharmaceutical • Biodetergents •Lysine animal feed additive • Farmaceutical ingredients •Vitamins food and feed • Cosmetic ingredients •Bio-colorants food industry • … •Enzymes technical aid •…..... PLA bioplastic (Cargill) Innovative bioproducts for sustainable production and consumption PLA is produced from renewable NatureWorks TM PLA bioplastic packaging corn resources through a combination of industrial biotechnology and enzymes conventional (chemical) polymerisation glucose PLA is a bioplastic comparable fermentation to conventional plastics lactic acid PLA is biodegradable and chemistry decomposes on the compost heap after use PLA bioplastic Fibres made The milk comes from PLA from mother nature Now, so does the bottle 2

Citric acid (over 1 million ton/year) Astaxanthin colorant Citric acid is used as Astaxanthin is a natural an organic acid in β -carotenoid colorant and many foodstuffs and in is produced by the red washing powders as a Fish feed yeast Xanthophyllomyces phosphate replacer dendrorhous Production with the fungus Aspergillus niger Glycolipids: microbial synthesis of biosurfactants sophorolipids ( Candida bombicola ) rhamnolipids ( Pseudomonas aeruginosa) Corn Rapeseed Biofuels: e.g. bio-ethanol sugar fermentation fermentation glucose to glycolipid biosurfactants Mixture of distillation carbohydrates Bio-ethanol (50 M ton/jaar) 3

valorisation of byproducts Biotechnological succinate production of the bio-ethanol production as a green route to many base chemicals yeast fermentation cereals bio-ethanol CO 2 glucose succinate bacterial fermentation bioplastics chemicals Handicaps in the development Antibiotics (about 30.000 ton/year) of the biobased economy • Technological handicap : For combatting infectious The used technologies are still at the beginning of diseases in humans and their development mature petrochemistry animals Penicillin G • Investment handicap: most biorefineries still need to be built existing petrochemical factories • Scale handicap: most biorefineries still have a relatively small scale economies of scale of large petroleum refineries Rapamycin Rifamycin B Eromycin Learning curve of bio-ethanol production Processing cost ($/GJ) 100 Ethanol Producers: Brazil 1980 1996 1986 10 2002 1990 1993 1999 Open innovation and education center Gasoline: Rotterdam 1 for the biobased economy 0 50 100 150 200 250 Accumulated Ethanol Production (Million m 3 ) 4

Problem #1: Problem #2: Gap in the innovation chain Lack of process operators for biobased industries Research Development Products Final use Science �� Technology � � Production �� Market • Declining student interest for technical studies Intellectual Industrial Know-How ROI Property Property • Shortage of operators for process industries in general • Knowledge and expertise are present but… • Lack of visibility of the biobased economy • Insufficient translation of knowledge into industrial innovation Need for a dedicated training facility for • Not enough value creation on scientific results process operators in biobased industries Need for a multipurpose pilot plant for biobased products and processes: Bio Base Europe Bio Base Europe Innovation and training for a sustainable biobased economy Innovation and training for a sustainable biobased economy Facts & figures Location Terneuzen: Training Center investment employees Million € FTE Pilot Plant 13 32 Location Gent: Pilot Plant Training Center 8 12 Total 21 44 The Bio Base Europe Pilot Plant The Bio Base Europe Pilot Plant Multipurpose pilot facility with its own specialized personnel Activities: • One-stop-shop : the whole value chain from the green resource – Development and optimization of biobased processes • to the final product can be performed in the same plant covering a wide range of technologies: biomass fractionation, fermentation, bioconversion, green chemistry, up-stream and Open innovation model : • down-stream processing – Service model : Pilot projects are performed for customers – Scale-up of biobased processes up to 10 m³/ton scale that maintain the rights to the developed technology – Custom manufacturing : production of ton quantities of new – Accessible: The Bio Base Europe Pilot Plant is open for bioproducts for testing the application and market potential all companies and research partners from chemical, energy, agro-industrial, food,… sector 5

The Bio Base Europe Pilot Plant Terneuzen (Nl) Ghent (B) Bio Base Europe Pilot Plant 6

Bio Base Europe Pilot Plant Fermentation and biocatalysis equipment up to 10 m³ scale Green chemistry equipment up to 10 m³ scale Up-stream and down-stream processing equipment • Plant fractionation • Biomass pretreatment: steam explosion, acid/base hydrolysis • Fysical separation: filtration, centrifugation,… • Evaporation • Crystallisation • Ion exchange and electrodialysis • Membrane separation: microfiltration, ultrafiltration,… • … Bio Base Europe Training Center Bio Base Europe Training Center Bio Base Europe Training Center Bio Base Europe Training Center 7

Conclusion and perspectives The world is going through a transition to a biobased economy. For this development we need new technology and new people There is a poor transfer of basic technology to production scale and a lack of process operators for biobased processes Speeding up the development of a sustainable biobased economy Bio Base Europe addresses these problems through a Pilot Plant and a Training Center for the biobased economy www.bbeu.org Bio Base Europe is an open innovation and education initiative and is open for business to all players of the biobased economy 8

Recommend

More recommend