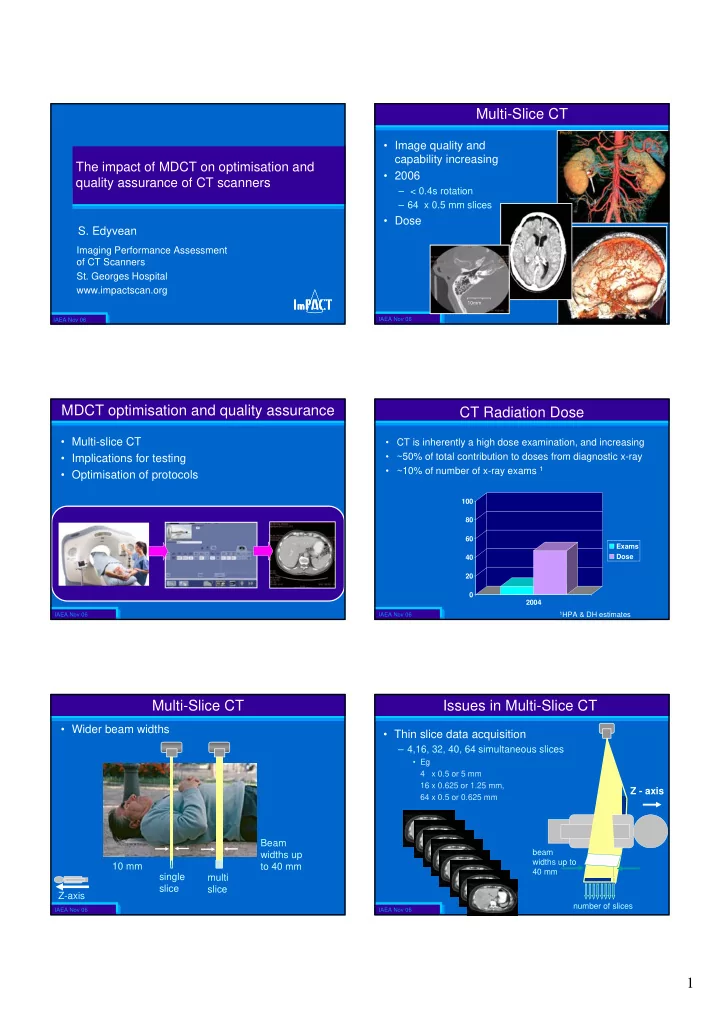

Multi-Slice CT • Image quality and capability increasing The impact of MDCT on optimisation and • 2006 quality assurance of CT scanners – < 0.4s rotation – 64 x 0.5 mm slices • Dose S. Edyvean Imaging Performance Assessment of CT Scanners St. Georges Hospital www.impactscan.org ImPACT ImPACT 10mm 2 IAEA Nov 06 IAEA Nov 06 MDCT optimisation and quality assurance CT Radiation Dose • Multi-slice CT • CT is inherently a high dose examination, and increasing • ~50% of total contribution to doses from diagnostic x-ray • Implications for testing • ~10% of number of x-ray exams 1 • Optimisation of protocols 100 80 60 Exams Dose 40 20 0 2004 3 4 IAEA Nov 06 IAEA Nov 06 1 HPA & DH estimates Multi-Slice CT Issues in Multi-Slice CT • Wider beam widths • Thin slice data acquisition – 4,16, 32, 40, 64 simultaneous slices • Eg 4 x 0.5 or 5 mm 16 x 0.625 or 1.25 mm, Z - axis 64 x 0.5 or 0.625 mm Beam beam widths up widths up to 10 mm to 40 mm 40 mm single multi slice slice Z-axis 6 7 number of slices IAEA Nov 06 IAEA Nov 06 1

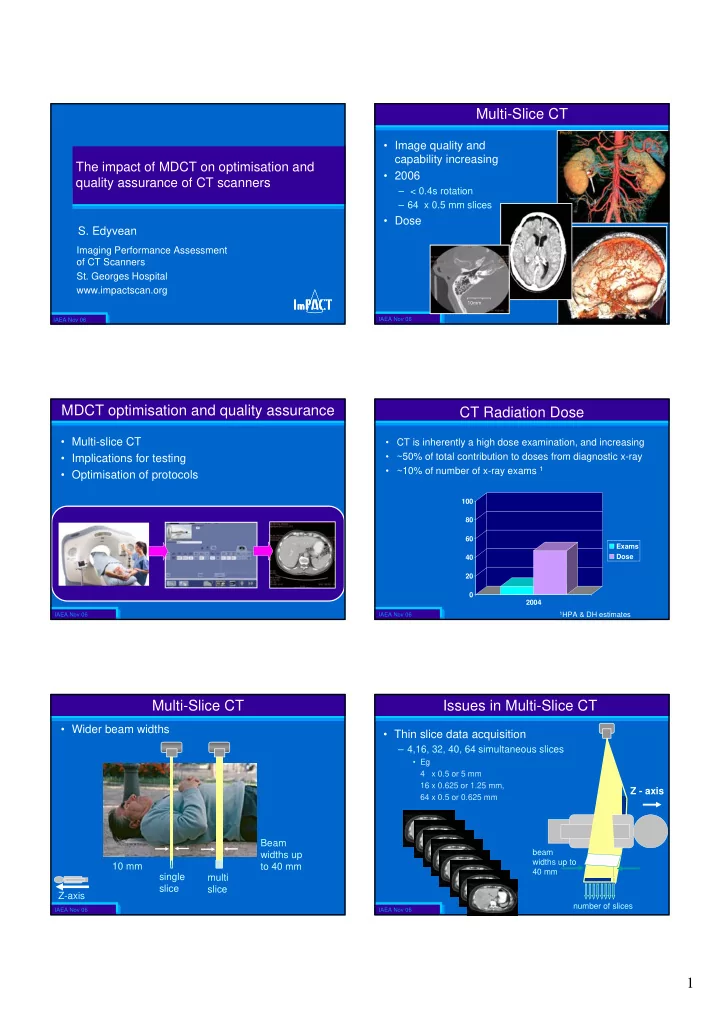

Multi-Slice CT Multi-Slice CT • Wider beam widths • Thinner slices and more of them Z - axis 10 mm 20, 24, 32 mm 29, 32, 40 mm 64 x 0.5 = 32 mm 16 x 0.5 = 8 mm 4 x 0.5 = 2 mm z-axis single slice 64 slice 4 - 16 slice Toshiba Aquilion series 8 9 Detector mock-ups courtesy of Toshiba IAEA Nov 06 IAEA Nov 06 Multi-Slice CT Multi-Slice CT • Axial scans • Rotating tube and detectors – same as single slice – Limited to ~ 16 slices, even on a 64 slice scanner • Many axial images – Cone beam effect • Helical scanning – many data sets Power Data 20 mm 10 11 IAEA Nov 06 IAEA Nov 06 Multi-Slice CT Multi-Slice CT • Helical scanning – one acquisition • Helical scanning – one acquisition – All channels acquire data (4,16, 64 slice scanner) – All channels acquire data (4,16, 64 slice scanner) – Each image uses data from many detectors – Each image uses data from many detectors – Reconstruct many images from one scan Recon position 1 Recon position 1 12 13 IAEA Nov 06 IAEA Nov 06 2

Multi-Slice CT Multi-Slice CT • Helical scanning – one acquisition • Automatic exposure control – All channels acquire data (4,16, 64 slice scanner) – Varying attenuation of, along, and around patients – Tube current automatically adjusted to achieve a standard – Each image uses data from many detectors noise level – Reconstruct many images from one scan – Reconstruct other thicknesses From patient to patient Along patient length Around the patient – Most scanning done helically Recon position 2 14 15 IAEA Nov 06 IAEA Nov 06 CT scanner technical quality Multi-Slice CT • Automatic exposure control • Quality control part of overall testing process – Varying attenuation of, along, and around patients • Many of the tests are the same – Tube current automatically adjusted to achieve a standard noise level – Scanners do all or some From patient to patient Along patient length Around the patient mA Quality Purchase Acceptance control High mA Low mA mA 16 17 -180 +180 angle IAEA Nov 06 IAEA Nov 06 References and resources IPEM Report 91 (2005) IPEM Report 32 (2003) www.ipem.org.uk www.impactscan.org Part III Computed Tomography Chapter 12 CT How and why What to do and when (IPEM) Institute of Physics and Engineering in Medicine 18 19 IAEA Nov 06 IAEA Nov 06 3

References and resources Issues in multi-slice CT testing • Wider irradiated beam • American College of Radiology www.acr.org – Is the test object long enough ? – CT Accreditation program ( Med. Phys, 31 (9) September 2004) • Many slices acquired simultaneously – Practical tips, artefact examples, pitfalls to avoid – Should I measure all the axial slices ? • AAPM, RSNA – Can I deal with all the images ? – www.aapm.org • Thinner slices – www.rsna.org – Is the test object good enough ? • Automatic exposure control – What should I do ? • Mainly helical protocols 20 21 IAEA Nov 06 IAEA Nov 06 CT scanner tests Image noise • Image quality water filled phantom noise image – image noise – imaged slice thickness – spatial resolution • Dose – CTDI (in air, in phantom) region of • AEC interest (roi) • Axial or helical scan • Noise = standard deviation ( σ ) of CT number in roi • roi ~ 40% of phantom diameter for repeatable results 22 23 IAEA Nov 06 IAEA Nov 06 Is the test object long enough ? Should I measure all the axial slices ? • Phantom long enough to accommodate all slices • For equal noise in each slice need • Don’t forget scatter – Equal sensitivity of detectors – Equal dose to detectors 120 • On four slice scanners, outer slices ~ 5% higher Catphan (20 → 40 mm) 20 – 40 mm ImPACT (30 → 120 mm) Manufacturer’s phantom 24 25 IAEA Nov 06 IAEA Nov 06 4

Noise measurements in multi-slice Should I measure all the axial slices ? • For equal noise in each slice need • Measure all or some of the slices – Equal sensitivity of detectors 1.60 – Equal dose to detectors • On four slice scanners, outer slices ~ 5% higher noise % 1.20 0.80 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Std Head Slice # Std Body 26 27 16 x 0.63 mm slices IAEA Nov 06 IAEA Nov 06 Noise measurements in multi-slice - helical Image slice thickness • In axial scan - determined by detector group • All detectors contribute to image – no need for four, eight or sixteen sets of images fwhm • Phantom length – Need to account for extra rotations at either end – Don’t forget scatter 28 29 IAEA Nov 06 IAEA Nov 06 Image slice thickness Image slice thickness - axial • In helical scanning - interpolated from helical data z-axis • 0.6 mm Al plate, • 30 degrees to scan plane fwhm • A typical test object – aluminium inclined plate • Some use wire, at 25, 30, or 45 º 30 31 IAEA Nov 06 IAEA Nov 06 5

Image slice thickness - axial Multi-slice imaged slice width - axial • Shown by width of plate projected into image • Most inserts are not long enough to measure all slices • Corrected for angle of plate • Scan in two positions Test object Imaged slice 16 slices fwhm z-axis z-axis 32 33 IAEA Nov 06 IAEA Nov 06 Multi-Slice CT Multi-slice imaged slice width - axial • As number of slices increases, beam is more • Beware slice at end of inclined plate diverging, outer slices are distorted – Image may look roughly ok, but data not true • Note end slice – cone beam effect 16 slices fwhm Slice at end of plate single four sixteen z-axis 34 35 IAEA Nov 06 IAEA Nov 06 Multi-slice imaged slice width - axial Multi-slice imaged slice width - axial • Measure all or some of the slices central slice outer slice (16 slice) 0.62 0.6 0.58 fwhm (mm) 0.56 0.54 0.52 0.5 0.48 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 Slice number 36 37 IAEA Nov 06 IAEA Nov 06 6

Multi-slice imaged slice width - axial Is my test object good enough ? • Measurement of slice widths of < 1mm • Shallow angle gives more pixels in projection in image – not possible where thickness of plate is < or = image width • More plates extend phantom in z-direction whilst staying • ImPACT use two phantoms close to the centre of the field of view z-axis – 0.5 mm aluminium, 30° (slices 2 - 20 mm) – 0.05 mm titanium, 8° (slices 0.5 - 4 mm) 8 ° pixel values 38 39 IAEA Nov 06 IAEA Nov 06 Imaged slice width – helical Imaged slice width – helical • Scan test object • High contrast bead or disc – Images reconstructed at • Same test for single and multi-slice sub-slice intervals – CT number in each image used to create the profile tungsten disk 2.5mm 0.05 mm 5mm 200 perspex rod 0.05 mm 150 perspex CT Numbers tungsten rod 100 thin disk FWHM FWTM 50 Helical Z-Sensitivity tool 0 -10 -8 -6 -4 -2 0 2 4 6 8 10 40 41 mm IAEA Nov 06 IAEA Nov 06 Scan plane spatial resolution MSCT - Scan plane spatial resolution • Same test for single and multi-slice • Subjective • Use for both axial and helical images – visual assessment of repeating pattern • Only need measure for one axial image • Objective – Factors affecting scan plane spatial resolution are in the scan plane, and do not change from slice to slice – calculation of MTF • edge • bead, wire 100 90 80 MTF (%) 70 60 50 40 30 20 10 0 0 2 4 6 8 10 Frequency (lp/cm) 42 43 IAEA Nov 06 IAEA Nov 06 7

Recommend

More recommend