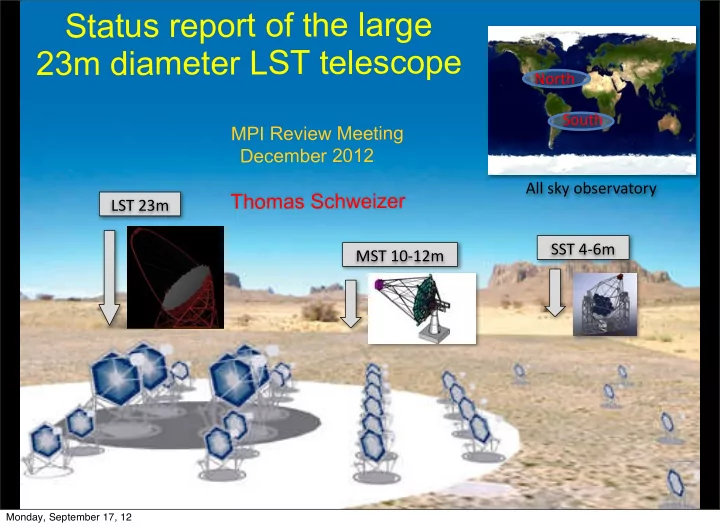

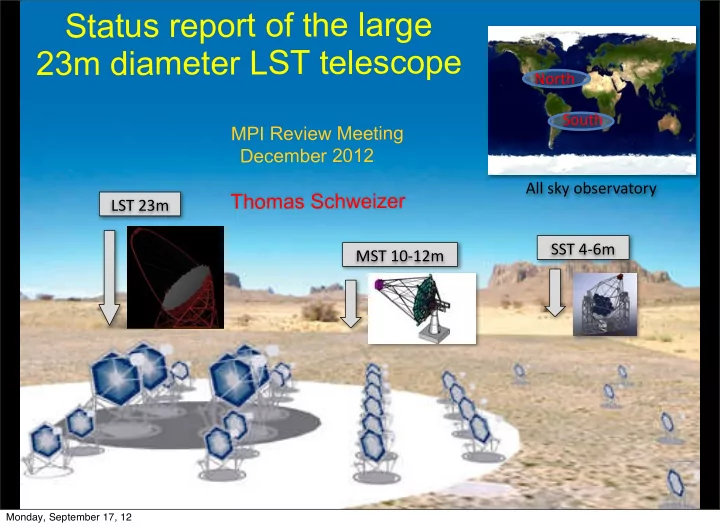

Status report of the large 23m diameter LST telescope North South M P I R e v i e w M e e t i n g D e c e m b e r 2 0 1 2 All ¡sky ¡observatory o m a s S c h w e i z e r T h LST ¡23m SST ¡4-‑6m MST ¡10-‑12m Thomas Schweizer, LST meeting Amsterdam, May 2012 Monday, September 17, 12

Rich Science cases with LSTs Trigger threshold: 15-20 GeV Binaries, Pulsars and other type of transients at low energy High-redshift AGNs and GRBs, Expand the Gamma Ray Horizon Analysis threshold: 20-30 GeV key physics cases: LST should be optimized in the energy range between 20 - 200 GeV Low energy threshold GRBs ¡(z<4) High ¡redshiA ¡AGNs ¡(z<2) Pulsars Binaries ¡and ¡transients Monday, September 17, 12

(1855ch camera) FOV = 4.5 degrees, Pixel size = 0.1 degrees 50 km/h wind Diameter: 23m Camera oscillation in wind gust: <8mm Dish area: about 400 m 2 Camera sagging: < 1 pixels F/D = 1.2, F=28m Dish profile: parabolic Dish profile: Parabolic Fast rotation: <180 deg/20 sec Permanent Active Mirror Control Light weight carbon fibre structure ~ 65 tons CTA Large Size Telescope: Structure by MPI Munich isochronicity: <0.6ns peak to peak Designed by MPI and MERO Monday, September 17, 12

Arch design Understructure Drive electronics Boggies + Drive system Ciemat, Madrid, Spain: Rail system + Foundation Camera Body IFAE, Barcelona, Spain: Spain, several institutes Trigger electronics + Data transfer Camera Frame Dish structure Japan: LST project coordination Telescope design + Mirrors MPI Munich: Readout electronics LAPP, Annecy, France CTA Large Size Telescope: Responsibilities by Institutes Designed by MPI and MERO Monday, September 17, 12

Will get new engineer Christopher Jablonski Eckart Lorenz LST Structure Designer with MERO: Thomas Schweizer LST structure coordinator: Masahiro Teshima CTA LST telescope project coordinator: Koji Noda Elevation drive: Glueing und carbon fibre expert: Holger Wetteskind LST Structure Project engineer: Thomas Haubold Mechanical workshop head: LST postdoc (new): Main LST team at MPI 5 Monday, September 17, 12

Understructure with carbon fibre tubes: high forces 2 technologies Tubes that have to hold up to 32 tons have glued end pieces with safety factor 4 on tubes (>130t), 5 (>150t) on glueing, 170mm diameter, 6-7 mm thickness Tubes that have to hold 32-65 tons Safety factor 4 on tubes (>260t), factor 1.8 on T-Igel endpiece (>130t), 280mm diameter, 10-12mm thickness glued Tubes on bottom, Steal Endpieces T-Igel endpiece Thomas Schweizer, LST meeting Amsterdam, May2012 Monday, September 17, 12

Glueing technology designed at MPI (Christopher Jablonski) 7 Monday, September 17, 12

Glueing test design (Christopher Jablonski) 8 Monday, September 17, 12

T-Igel endpiece design, flanch and cone (Christopher Jablonski) 9 Monday, September 17, 12

Segment of dish structure in MPI garden 10 Need 56m double focal length Monday, September 17, 12

Rack and Pinion drive system by F. Granena (IFAE) Monday, September 17, 12

RAIL & Foundation Design Monday, September 17, 12

Design of Drive electronics: LAPP LAPP IN2P3 Positioning speed in GRB follow up: 180 degrees / 20 sec Peak 220 kW during 8 sec Drive ¡MoOon ¡Controller Siemens ¡S120 ¡series Drive ¡PLC ¡system OPC ¡UA ¡test ¡is ¡on-‑going ¡ Velocity Synchronous ¡motors Siemens ¡FT7 ¡series ¡ AcceleraOon Monday, September 17, 12

Monday, September 17, 12

Dynamical calculation for Arch Monday, September 17, 12

Optical axis and permanent AMC (Active Mirror Control) Define optical axis with the IR Laser beams HR CCD camera at the center of dish to monitor the optical axis and star field Stars SKY LED LED OA-‑Lazer PMT ¡-‑ CAMERA MIR-‑Lazers MIR-‑Lazers Target LED LED IMAGE ¡with ¡HR ¡CCD ¡Camera pointing direction in sky (Camera LED position) ‒ (Optical axis Laser position) camera sag (Mirror Laser positions) ‒ (Optical axis Laser position) mirror direction Monday, September 17, 12

Mirror layout and mounting scheme supporting plate Mounting scheme Asymmetric telescope axis 205 Hex-shape mirrors of 2m 2 area) Total area ~405m 2 Monday, September 17, 12

1510mm LST MIRROR prototype at Sanko 2.7mm Glass+60mm Al.Honeycomb+2.7mm Glass Specifications SpuAering ¡Cr ¡+ ¡Al ¡+ ¡SiO2 ¡+ ¡HfO2 ¡+ ¡SiO2 SpuAering ¡mulF ¡layer ¡coat F2F : 1510mm Cr ¡+ ¡Al ¡+ ¡SiO2 ¡+HfO2 ¡+ ¡SiO2 Area : 2m 2 Reasonably ¡High ¡reflecFvity R: ¡56.0 ¡– ¡58.4 ¡m Strong ¡protecFve ¡surface D80 : ¡10mm(1/5 ¡pixel) Long ¡life ¡Fme Weight : ¡45kg Monday, September 17, 12

Camera design Monday, September 17, 12

Readout ¡Electronics ¡and ¡Water ¡Cooling 1GHz ¡samples/s, ¡4096 ¡memories/ch 3 ¡cluster ¡module Water ¡Cooling ¡plates ¡for Dragon ¡Cluster ¡module ¡ for ¡trigger ¡test ¡(1/80) 37 ¡cluster ¡modules ¡(1/8) for ¡7pmts ¡(1/265) Full ¡size Monday, September 17, 12

Testing water cooling of simulation PCB The ¡locaOon ¡of ¡FPGA ¡shows ¡70 ¡degreees. Just ¡with ¡Al. ¡Plate ¡is ¡not ¡so ¡bad. With ¡Al. ¡plate ¡+ ¡cooling ¡pies ¡looks ¡beeer w/o ¡Aluminum ¡plate, ¡heat ¡pipes, ¡floaOng w ¡Al. ¡plate, ¡contact ¡to ¡Water ¡C.P. w ¡Al. ¡plate, ¡heat ¡pipes, ¡contact ¡to ¡Water ¡C.P. Monday, September 17, 12

Alternative cooling with air Monday, September 17, 12

Testing air cooling Monday, September 17, 12

Testing air cooling Monday, September 17, 12

3-cluster camera Digital Trigger Analog Trigger Monday, September 17, 12

Tentative global time schedule Monday, September 17, 12

The end 26 Monday, September 17, 12

Test of Cooling plate Mini-Camera(37clusters, 1/8 LST camera) 10mm Φ 1000L Long holes water tank (works as chiller) pump 32L/min ~1m 20mm thickness aluminum plate 8 water channels/holes in the cooling plate 20 channels for full scale camera. Monday, September 17, 12

Test of water cooling plate cooling plate IR camera PC pump Water tank as a chiller Thermometer Monday, September 17, 12

Test of water cooling plate cooling plate IR camera PC pump Water tank as a chiller Thermometer Monday, September 17, 12

Monday, September 17, 12

Monday, September 17, 12

Winston Cone Prototyping in Japan 4Euro/pcs in mass production Designed ¡in ¡ICRR, ¡Ibaraki-‑U ¡and ¡Nagoya-‑U Monday, September 17, 12

Rail Design Monday, September 17, 12

Rail and bogey system Monday, September 17, 12

New ¡Actuator ¡700N. ¡SF=3 Monday, September 17, 12

Sanko Mirror #01 Monday, September 17, 12

Calculations for Wind by Ferran Granena (IFAE): We have uplift during storm Monday, September 17, 12

PMD system is installed at ICRR, U-Tokyo (developed by experts of Erlangen optic group) Installed ¡at ¡ICRR U.Tokyo Monday, September 17, 12

Monday, September 17, 12

Attach AMC Laser Holder 871.8mm 435.9mm 1743.6mm 1510mm 871.8mm 100.0mm 60.0mm Monday, September 17, 12

Attach AMC Laser Holder 871.8mm 435.9mm Cut ¡out 1743.6mm 1510mm 871.8mm 100.0mm 60.0mm Monday, September 17, 12

Attach AMC Laser Holder 871.8mm 435.9mm 1743.6mm 1510mm 871.8mm 100.0mm 60.0mm Monday, September 17, 12

XY ¡direcOon Z ¡direcOon Tilt ¡in ¡YZ ¡plane Monday, September 17, 12

Recommend

More recommend