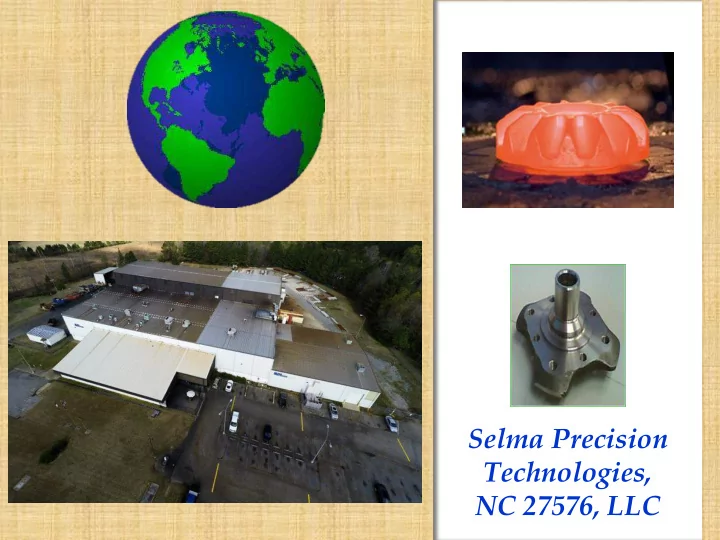

Selma Precision Technologies, NC 27576, LLC 1

Agenda • Introduction & Vision • Technical Capabilities of Net Formed Gears at SPT • Plan for Revival of SPT, NC, Selma Plant • Investment Plan • Staffing Plan & ISO Certification • Capacity Enhancement Plan : 2017, 2018 & 2019. • Warm Forging Capabilities (India) 2

Warm Group & SPT: Company Information • Vision : “Evolve Globally As The Most Preferred Supplier of Forged Precision Components for All Customers.” • Over 20 years experience in forging & precision machining technologies for critical components. • North America Market foot-print established in 2017 vide acquired facility of high precision net shaped bevel gears in Selma, North Carolina ( erstwhile Thyssen Krupp & SONA BLW) • Leveraging Technical capabilities of USA & INDIA to deliver QCD :(Quality, Cost & Delivery) to CUSTOMERS. 3

Strategic Win-Win Options : FOR ALL CUSTOMERS ! 1. SPT is willing to allocate 100% of Selma U.S. plant capacity as a long term “vendor partner”. 2. SPT is willing to supply fully / semi-finished machined components with competitive QCD options. 3. SPT is willing to look at contract manufacturing options as tier-2 / tier-3 supplier i.e. just for Forgings, Heat- Treatment, CNC machining, Broaching , etc. 4. All options that suit Customers Long Term & Current requirements. 4

Gear Tooth Flank Design Tooth Flank Design – Gear Design Program Master Gears Inspection Jig Master Gear & Pinion Tooth Flank Design Zenotech Presentation Inspection Jigs 5

Current Developments – Selma Plant India & Turkey India Current Stage: Die Manufacturing Current Stage: Tooth Flank Design Sample Submission: May.17 Sample Submission: June.17 We invite all CUSTOMERS to visit our facility in May 6

Bevel Gear – Tooth Flank Design 7

Bevel Gear Dies & Machining Fixture Design Gear Design from Flank Data Electrode Design Pre-form and Finish Tooth Die Design Coining Die Design Stan Perritte Eric Siegert Machining Nest Design Inspection Negative Design Software • Auto CAD • Solid Edge • NX Simulation • DeForm 8

Tooling Manufacturing Electrode Manufacturing Preform and Finish Tooth Die Coining Die Machining Nest Thomas Minaty Inspection Negative • HyperMILL HSC CAM • Mikron Model CNC for Graphite electrode • Die Sinker EDM M/Cs 9

Inspection using CMM Electrode Preform and Finish Tooth Die Coining Die Machining Nest Eric Siegert Inspection Negative Zeiss CMM • GearPro • Calypso • 10

Production Capability - Manpower Billet Cutting to Coining: Thomas Machining: Hogan Heat Treatment: Dinesh Sharma Logistic and Sales Contact: Gerhard Quality Inspection: Eric Siegert Project Manager: Amit Mehta (w.e.f June 2017) 11

Production Capability - Equipment Hot / Warm Forging Heat Treatment Machining Forging Press Lines Heat Treatment Soft & Hard Machining 1. 1,300 Ton Press • SQF – 4 Furnace • Mazak 2. 2,500 Ton Press • Tempering – 6 Furnaces • Mori Seiki 3. 2,500 Ton Press • Washing – 2 Machines • Weisser 4. 2,000 Ton – Automated • Endo-generator – 2 Nos • Kitako 5. 1,200 Ton Press • N 2 Generator – 1 No 6. 1,000 Ton – Automated Blasting and Coining Press Broaching Metallurgical Lab • Roesler, Hunziker, Tunnel • Microscope • 3 Station internal • 300 Ton – Automated Press • Micro-hardness Tester • 2 Station internal • 400 Ton Press • Surface Hardness Tester • 2 Station internal • 400 Ton Press • Specimen preparation • 630 Ton Press 12

Warm Group (India) 13

Warm Forging (India) Profile Business Profile Precision Hot Forged, Cold Forged & Machined Automotive Parts Company Name Warm Forgings Pvt. Ltd. Customers All Major OEMs/Tier 1 in India Quality Certification TS 16949 Certified Annual Sales Approx. $30 Million Volumes 1.25 Million parts per month Manufacturing Locations Two Bhiwadi, Rajasthan (North India) Bangalore, Karnataka (South India) Number of Employees 1100 14

India Locations Bhiwadi (Rajasthan) Forging & Machining 100,000 Sq. Meter Indore proposed Bengaluru Forging & Machining 8,000 Sq. Feet 15

Design & Development Capabilities Design Software: 1. Solid Edge 2. NX, Unigraphics 3. Delcam, Tool Room Machines: 1. High Speed Machining Centre – 3Axis (Korean) 2. CNC Turning Centre 3. Precision Turning Lathes 4. M1TR 5. EDM ZNC (Taiwan) 6. Milling Machines 100% In house Manufacturing Facilities of Forging Dies and Tooling 16

Inspection & Testing Facilities Portable Spectrometer Metallurgical Lab Raw Material Verification 17

Inspection & Testing Facilities Contour Tracer Contour Tracer CMM - Mitutoyo 18

Bevel Gear Testing Angular Gear Roll Tester Gleason-6A 19

Forging Capabilities Forging Capacity: 2000 Ton/Month (about 1.25 million 20 parts per month)

Machining Capabilities 21

Heat Treatment Capabilities Equipment Type Process Capacity Qty. Pit Type Furnace Through Hardening, Normalizing 600 Kgs 2 Continuous Normalizing 9 Ton 1 Furnace Continuous Hardening, Tempering, Isothermal 18 Ton 1 Furnace Annealing Pit Type Furnace Spheroids Annealing 2 Ton 1 • Hardening • Tempering • Normalising • Iso Thermal Annealing • Spheroids Annealing • Through Hardening 22

Customers 23

Share of Business Revenue in USD (Millions) 0.6, 7% 0.3, 3% Mitsuba 3.2, 36% Volvo Commercial 1.9, 21% Musashi India Yamaha India Nippon 2.9, 33% 24

Product Range (Precision Forged & Machined) 220.0 MM 25

Product Range (Precision Forged & Machined) 26

Product Range (Precision Forged & Machined) 27

Product Range (Rotavators) Diameter: Up to 250 mm Module: Up to 6 28

Product Range (Flanges) 29

Product Range (Linamar Italy) Diameter: Up to 250 mm Weight: Up to 8.0 Kg 30

THANK YOU ! Thank You for Your time and Patience! We will highly appreciate an appointment to meet and explain our plans for a “WIN - WIN” Business Relationship with ALL OUR VALUABLE CUSTOMERS. 31

Contact Details Name Email ID Phone Number Amit Rajput arajput@sptechnc.com (919)758-3686 md@warmforging.com Vinay Upadhyay vupadhyay@sptechnc.co (919)325-6604 m vinay301059@gmail.com Thomas Minaty tminaty@sptechnc.com (919)795-7665 Amit Mehta amehta@sptechnc.com (919)348-8448 Dinesh Sharma dsharma@sptechnc.com (919)455-3653 Stan Perritte sperritte@sptechnc.com (919)208-8307 Eric Siegert esiegert69@sptechnc.co (919)351-4144 m Gerhard gschicktanz@sptechnc.c (919)412-2200 Schicktanz om 32

Recommend

More recommend