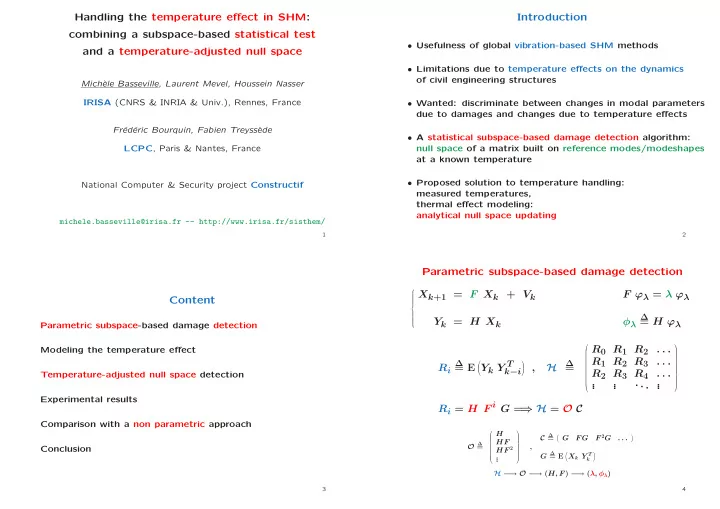

Handling the temperature effect in SHM: Introduction combining a subspace-based statistical test • Usefulness of global vibration-based SHM methods and a temperature-adjusted null space • Limitations due to temperature effects on the dynamics of civil engineering structures Mich` ele Basseville, Laurent Mevel, Houssein Nasser IRISA (CNRS & INRIA & Univ.), Rennes, France • Wanted: discriminate between changes in modal parameters due to damages and changes due to temperature effects Fr´ ed´ eric Bourquin, Fabien Treyss` ede • A statistical subspace-based damage detection algorithm: LCPC , Paris & Nantes, France null space of a matrix built on reference modes/modeshapes at a known temperature • Proposed solution to temperature handling: National Computer & Security project Constructif measured temperatures, thermal effect modeling: analytical null space updating michele.basseville@irisa.fr -- http://www.irisa.fr/sisthem/ 1 2 Parametric subspace-based damage detection X k +1 = F X k + V k F ϕ λ = λ ϕ λ Content ∆ Y k = H X k φ λ = H ϕ λ Parametric subspace-based damage detection R 0 R 1 R 2 . . . Modeling the temperature effect R 1 R 2 R 3 . . . ∆ Y k Y T ∆ , R i = E H = k − i R 2 R 3 R 4 . . . Temperature-adjusted null space detection . . ... . . . . . . . Experimental results R i = H F i G = ⇒ H = O C Comparison with a non parametric approach � G H � C ∆ F 2 G = F G . . . HF O ∆ = , Conclusion HF 2 � � G ∆ X k Y T . = E . . k H − → O − → ( H, F ) − → ( λ, φ λ ) 3 4

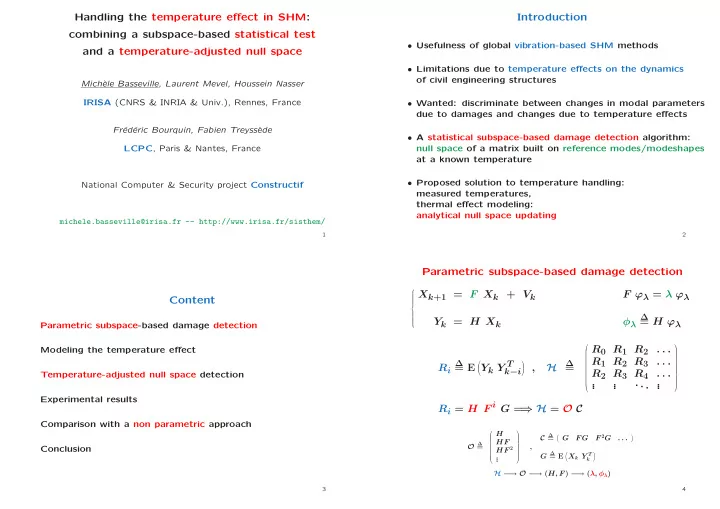

Λ modes θ ∆ Modeling the temperature effect Canonical parameter : = vec Φ mode shapes Clamped, planar, axially pre-stressed, Euler-Bernoulli beam Φ Φ∆ Observability in modal basis : O p +1 ( θ ) = . . . EI d 4 w ( x ) d 2 w ( x ) Φ∆ p − ρA ω 2 w ( x ) = 0 − N 0 dx 4 dx 2 θ 0 : reference parameter for safe structure Eigen problem � dw ( x ) � � Left null space: S T S = I s , S T O p +1 ( θ 0 ) = 0 � w ( x ) | x =0 ,L = 0 ; = 0 � � dx � � x =0 ,L with ω ∆ w = w ω ∆ = ln | λ | , = φ λ , w ( x ) : transversal displacement. Y k : N -size sample of new measurements E, I, ρ, A : Young’s modulus, cross-section inertia momentum, Residual for SHM: density and cross-sectional area. = vec( S T ( θ 0 ) ˆ ζ N ( θ 0 ) ∆ H ) N 0 : quasi-static axial preload in Newton: ε ( x ) ∆ δT ∆ N 0 = EA ε ( x ) , = ε 0 ( x ) − α δT , = T 0 ( x ) − T ref J ( θ 0 ) : sensitivity of ζ w.r.t. modal changes; Σ( θ 0 ) : covariance ε 0 : mechanical strain, T 0 : current temperature, T ref : reference N Σ − 1 J ( J T Σ − 1 J ) − 1 J T Σ − 1 ζ N ≥ h χ 2 -test: ζ T (no stress) temperature, α : thermal expansion coefficient. 5 6 Temperature-adjusted null space detection N 0 remains spatially constant (no external axial body forces, no axial surface tractions, gravity effects negligible). • θ 0 : reference modal parameter for safe structure Only one measure at a given point is necessary: Thermally compensated strain gauges measure ε ( x ) = N 0 /EA . • Y k : N -size sample of new measurements; T recorded Solutions of the eigen problem: 2 γ − n γ + n (1 − cos( γ − n L ) cosh( γ + n L ))+( γ + 2 − γ − 2 ) sin( γ − n L ) sinh( γ + n L ) = 0 • Update the modal parameter θ T : n n with : � 1 / 2 � 2 + δT − → ε ( x ) − → ( ω n ) n − → ( λ n , ϕ n ) n − → θ T � + ρA N 0 − N 0 � − � EI ω 2 γ n = � n + � � 2 EI 2 EI • Update the null space S ( θ T ) Solved numerically (no analytical solutions for the clamped case). Analytic expression for mode shapes. • Compute the residual ζ N ( θ T ) ∆ = vec( S T ( θ T ) ˆ H ) Pre-stress effects on mode shapes are negligible • Compute the χ 2 -test (numerical results). 7 8

Example - Beam within a climatic chamber Decreasing temperature effect on the first 4 frequencies • A laboratory test-case provided by LCPC 60 154 safe − theory safe − theory Climatic chamber in Nantes safe − identify(cosmad) safe − identify(cosmad) damaged − identify(cosmad) damaged − identify(cosmad) 59 152 58 150 • Vertical clamped beam 57 Second − Frequency First − Frequency 56 148 subject to decreasing temperatures 55 146 54 • Small local damage: horizontal clamped spring attached 144 53 to the beam, with tunable stiffness and height 52 142 20 30 40 50 60 70 80 90 100 110 120 20 30 40 50 60 70 80 90 100 110 120 ε x − αθ ( µ m/m) ε x − αθ ( µ m/m) 288 466 safe − theory safe − theory safe − identify(cosmad) safe − identify(cosmad) damaged − identify(cosmad) damaged − identify(cosmad) 464 286 462 284 Third − Frequency Fourth − Frequency 460 282 458 280 456 278 454 276 452 20 30 40 50 60 70 80 90 100 110 120 20 30 40 50 60 70 80 90 100 110 120 ε x − αθ ( µ m/m) ε x − αθ ( µ m/m) First 4 frequencies vs. thermal constraint. Computed (black) and identified (safe, damaged) 9 10 Implementation issues Handling the temperature effect 7 6 6 x 10 5 x 10 4.5 5 4 • Frequencies : computed � = identified 3.5 4 3 χ 2 3 χ 2 2.5 (the clamped boundary condition, obtained with 2 2 1.5 1 tightening jaws, is not perfect) 1 0.5 0 0 20 30 40 50 60 70 80 90 100 110 120 20 30 40 50 60 70 80 90 100 110 120 ε x − αθ ( µ m/m) ε x − αθ ( µ m/m) Original χ 2 -test New χ 2 -test De-biased temperature-adjusted modal parameter: 7 6 6 x 10 5 x 10 θ T ( ε ) ∆ safe safe ( ∀ ε ) � = θ T ( ε ) + θ 0 ( ε 0 ) − θ T ( ε 0 ) � damaged damaged 4.5 5 4 3.5 4 3 E( χ 2 ) E( χ 2 ) 3 2.5 2 2 • Compute the key matrices: 1.5 1 1 residual sensitivity J and covariance Σ 0.5 0 20 30 40 50 60 70 80 90 100 110 120 20 30 40 50 60 70 80 90 100 110 120 ε x − αθ ( µ m/m) ε x − αθ ( µ m/m) Original - Average New - Average for every realization of each scenario Safe and damaged 11 12

Conclusion Comparison with a non parametric approach: empirical null space merging data at # temperatures Temperature effect in vibration-based SHM 7 6 6 6 x 10 5 x 10 14 x 10 Statistical parametric model-based approach 4.5 12 5 4 10 3.5 4 3 Statistical subspace-based damage detection algorithm 8 χ 2 3 χ 2 2.5 χ 2 6 2 2 1.5 4 1 Temperature-adjusted null space 1 2 0.5 0 0 0 20 30 40 50 60 70 80 90 100 110 120 20 30 40 50 60 70 80 90 100 110 120 20 30 40 50 60 70 80 90 100 110 120 ε x − αθ ( µ m/m) ε x − αθ ( µ m/m) ε x − αθ ( µ m/m) Original χ 2 -test Analytical updating Empirical merging Example: clamped beam within climatic chamber 6 x 10 7 5 x 10 6 14 x 10 6 safe safe safe damaged damaged damaged 4.5 12 5 4 Comparison with a non parametric approach 10 4 3.5 8 3 (empirical null space, merging data at # temperatures) E( χ 2 ) E( χ 2 ) E( χ 2 ) 3 2.5 6 2 2 4 1.5 1 Ongoing: statistical nuisance rejection 2 1 0.5 0 0 20 30 40 50 60 70 80 90 100 110 120 20 30 40 50 60 70 80 90 100 110 120 20 30 40 50 60 70 80 90 100 110 120 ε x − αθ ( µ m/m) ε x − αθ ( µ m/m) ε x − αθ ( µ m/m) Average Average Average Future: in-operation examples, extension to 3D temperature fields, Safe and damaged thermal model parameterization 13 14

Recommend

More recommend