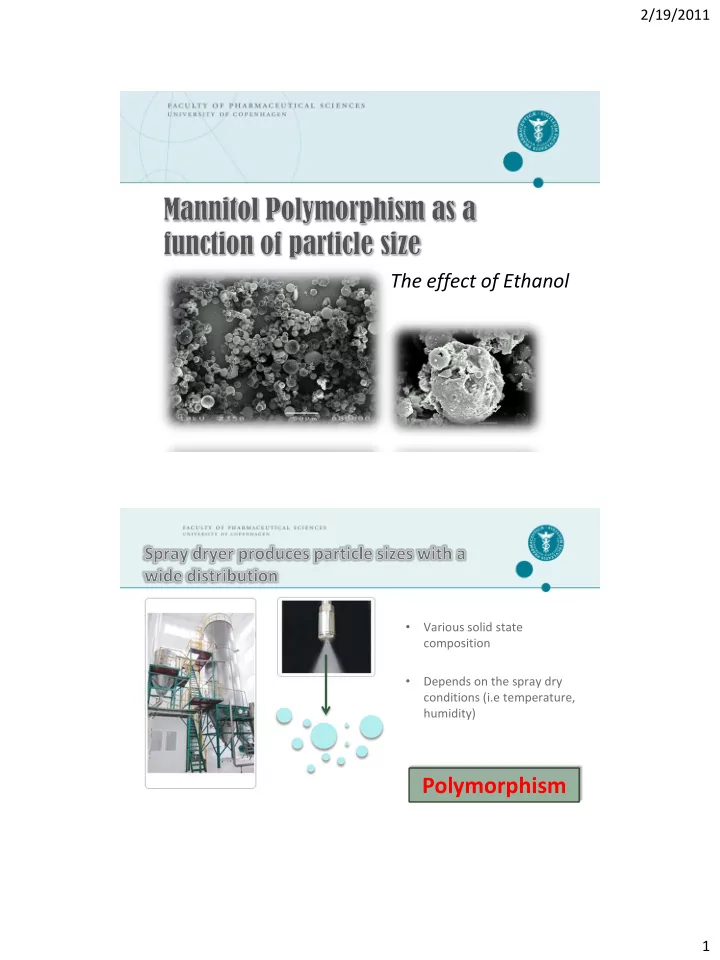

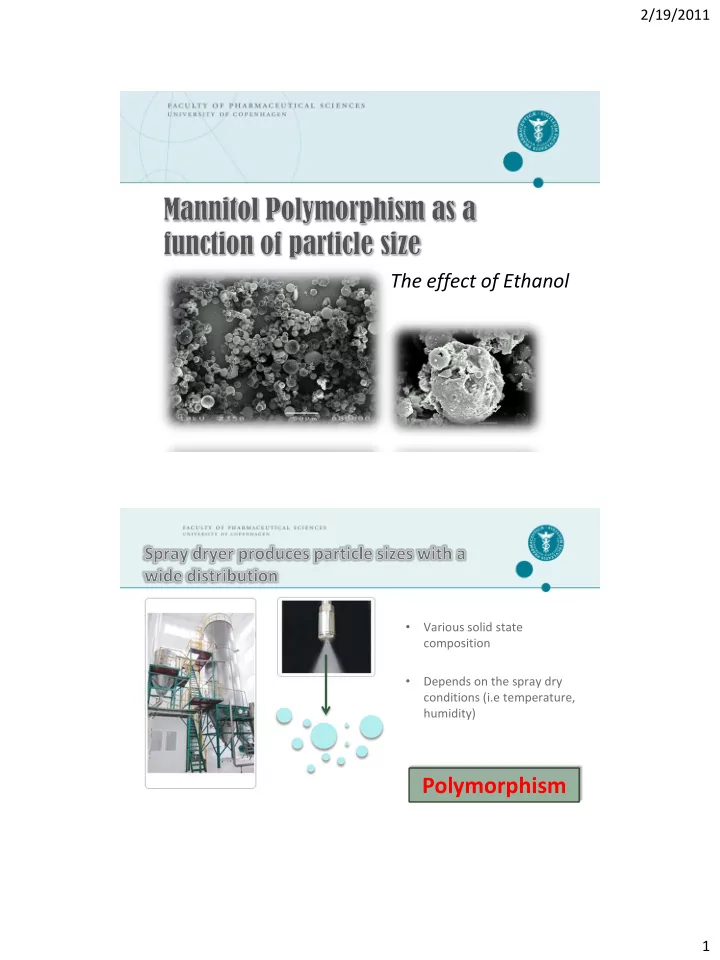

2/19/2011 The effect of Ethanol • Various solid state composition • Depends on the spray dry conditions (i.e temperature, humidity) Polymorphism 1

2/19/2011 Aims Assess if polymorphic change follows the trend linked to the particle size distribution that is normally obtained during spray dry process. To investigate the effect of ethanol on drying kinectics, which then affect the crystal growth and drying behavior of polymorphs . Methods 2 3 Raman Microscopy MATERIALS CHEMO-METRICS NGI • D-Mannitol Multivariate Data Separate to Analysis α , β , δ and SOLID STATE different particle PLS-DA ANALYSIS size fractions hemihydrate Characterize • Ethanol (Stage 1 – Stage 8) 4 mannitol polymophrs 1 Scanning X-RAY Diffracto- DATA INTERPRE- Electron TATION Micrograph / metry SPRAY DRY Thermogravi- Mannitol in Identify metric Analysis polymrphic 10% Ethanol change according to particle size 2

2/19/2011 Results – SEM / TGA Stage 1 Stage 4 Stage 7,8 10.9 ± 3.4 µm 2.7 ± 1.7 µm 1.0 ± 0.4 µm TGA - No detectable weight loss Results - XRD 10% Ethanol S78 Stage 7,8 S6 • All samples contain S5 Stage 6 α and β -mannitol. S4 Stage 5 S3 S2 • Comparing the ratio Stage 4 S1 Bulk of two polymorphs Offset Y values Stage 3 at indicated positions, α Stage 2 contents increase relatively at smaller Stage 1 particle size. Bulk α 5 10 15 20 25 30 35 40 α β β 2 Theta 3

2/19/2011 Results – Raman Microscopy (b) Loading 1, 86.54% (a) alpha mannitol Loading 2, 13.15% 0.15 beta mannitol 30000 Loading 3, 0.25% 0.10 25000 0.05 20000 Intensity 0.00 15000 -0.05 10000 -0.10 5000 -0.15 0 400 600 800 1000 1200 1400 400 600 800 1000 1200 1400 -1 ) Wavenumber (cm -1 ) Wavenumber (cm • 3 principal components • 100% specificity and sensitivity • 0% misclassification rate Results – Raman Microscopy (c) 100 90 Percentage of beta mannitol (%) 80 • Content of 70 β -mannitol 60 decreased from 50 NGI Stage 1 to 8 40 30 20 10 0 -- Bulk powder -- S 1 S 2 S 3 S 4 S 5 S 6 S 7 S 8 NGI stage 4

2/19/2011 Different drying rates for droplets with various sizes 5 secs 1 sec • Smaller droplets are likely to dry faster than larger droplets • Ostwald rules of stages – more meta-stable α -mannitol in small particles • Moisture as ‘lubricant’ for stable crystal arrangement – more stable β -mannitol in large particles Conclusions • Ethanol increases drying rate of mannitol in the spray drying system, leading to the presence of meta-stable α -mannitol in addition to stable β - mannitol. • Polymorphic form of mannitol changes according to particle size from spray drying process. 5

Recommend

More recommend