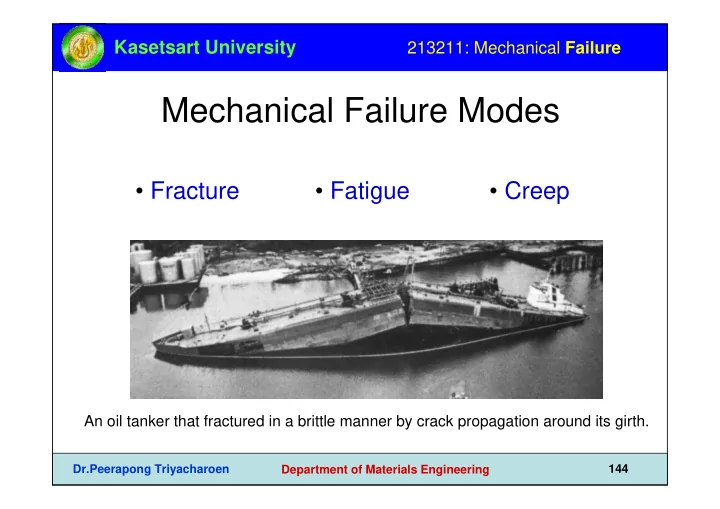

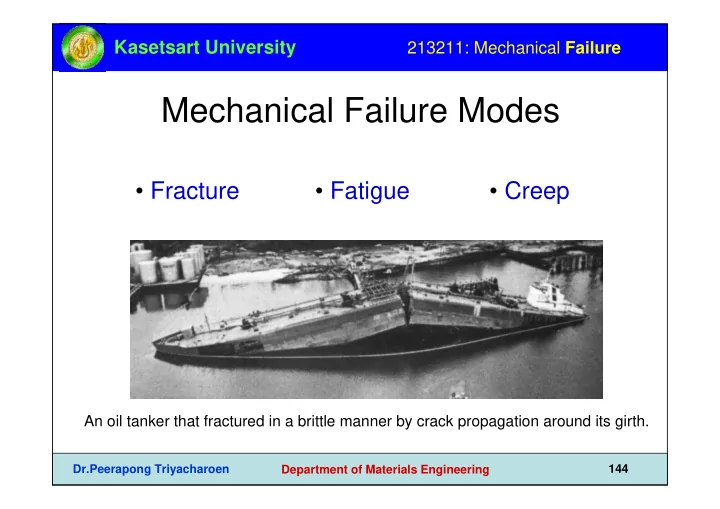

Kasetsart University 213211: Mechanical Failure Mechanical Failure Modes • Fracture • Fatigue • Creep An oil tanker that fractured in a brittle manner by crack propagation around its girth. 144 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Ductile vs. Brittle Fracture Very Modulate Fracture behavior: Brittle Ductile Ductile Ductile fracture is desirable! Ductile: warning before fracture Brittle: No warning %RA or %EL: Large Moderate Small 145 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Example: Failure of a pipe • Ductile failure: --one piece --large deformation • Brittle failure: --many pieces --small deformation 146 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Moderately Ductile Fracture void growth void shearing necking fracture and linkage nucleation at surface σ • Resulting 50 mm 50 µ m fracture surfaces (steel) Particles serve as 100 µ m void nucleation sites. 147 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Brittle Fracture • Trangranular (between grains) • Intergranular (within grains) 304 S. Steel 4 mm 316 S. Steel 160 µ m Polypropylene Al Oxide 3 µ m 1 mm 148 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Impact Testing 149 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Temperature Dependence of Impact Energy More Ductile Brittle Ductile to Brittle Transition Temperature 150 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Design Strategy: Stay Above The DBTT! • Pre-WWII: The Titanic • WWII: Liberty ships • Problem: Used a type of steel with a DBTT ~ Room temp. 151 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Fatigue • Fatigue = failure under cyclic stress. compression on top specimen counter bearing motor bearing flex coupling tension on bottom σ σ max • Stress varies with time. --key parameters are S and σ m S σ m σ min time • Key points: Fatigue... --can cause part failure, even though σ max < σ c . --causes ~ 90% of mechanical engineering failures. 152 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Fatigue Design Parameter S = stress amplitude case for • Fatigue limit, S fat : unsafe steel (typ.) --no fatigue if S < S fat Sfat safe 103 105 107 109 N = Cycles to failure S = stress amplitude case for • Sometimes, the Al (typ.) unsafe fatigue limit is zero! safe 103 105 107 109 N = Cycles to failure 153 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Improving Fatigue Life S = stress amplitude 1. Impose a compressive surface stress near zero or compressive σ m (to suppress surface moderate tensile σ m larger tensile σ m cracks from growing) N = Cycles to failure --Method 1: shot peening --Method 2: carburizing shot C-rich gas put surface into compression better bad 2. Remove stress concentrators. bad better 154 Dr.Peerapong Triyacharoen Department of Materials Engineering

Kasetsart University 213211: Mechanical Failure Creep • Occurs at elevated temperature, T > 0.4 T melt • Deformation changes with time. strain, ε σ σ,ε INCREASING T tertiary t 0 primary secondary elastic T < 0.4 Tm time 0 155 Dr.Peerapong Triyacharoen Department of Materials Engineering

Recommend

More recommend