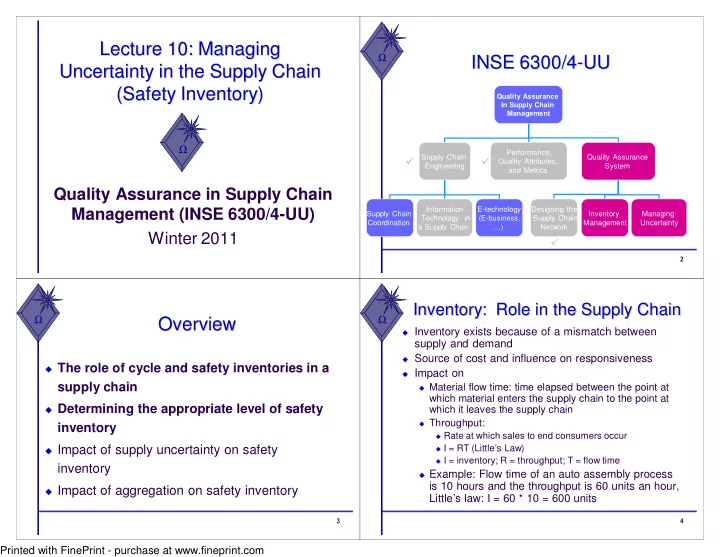

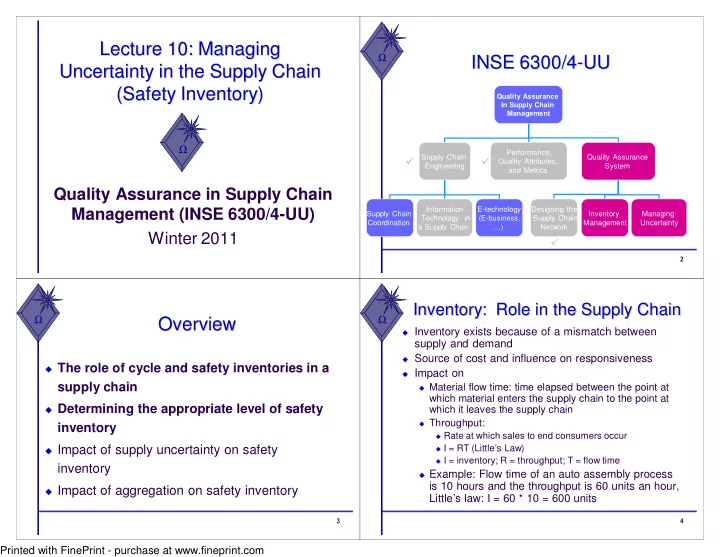

Lecture 10: Managing Lecture 10: Managing Ω INSE 6300/4 INSE 6300/4- -UU UU Uncertainty in the Supply Chain Uncertainty in the Supply Chain (Safety Inventory) (Safety Inventory) Quality Assurance In Supply Chain Management Ω Performance, Supply Chain Quality Assurance � � Quality Attributes, Engineering System and Metrics Quality Assurance in Supply Chain Information E-technology Designing the Management (INSE 6300/4-UU) Supply Chain Inventory Managing Technology in (E-business, Supply Chain Coordination Management Uncertainty a Supply Chain …) Network Winter 2011 � � Inventory: Role in the Supply Chain Inventory: Role in the Supply Chain Ω Ω Overview Overview � Inventory exists because of a mismatch between supply and demand � Source of cost and influence on responsiveness � The role of cycle and safety inventories in a � Impact on supply chain � Material flow time: time elapsed between the point at which material enters the supply chain to the point at � Determining the appropriate level of safety which it leaves the supply chain � Throughput: inventory � Rate at which sales to end consumers occur � Impact of supply uncertainty on safety � I = RT (Little’s Law) � I = inventory; R = throughput; T = flow time inventory � Example: Flow time of an auto assembly process is 10 hours and the throughput is 60 units an hour, � Impact of aggregation on safety inventory Little’s law: I = 60 * 10 = 600 units � � Printed with FinePrint - purchase at www.fineprint.com

Cycle Inventory Cycle Inventory Role of Cycle Inventory Role of Cycle Inventory Ω Ω in a Supply Chain in a Supply Chain Process several flow units collectively at a given moment � Lot, or batch size: quantity that a supply chain stage in time either produces or orders at a given time New shipment arrives � Cycle inventory: average inventory that builds up in New shipment Inventory Inventory 20 20 arrives the supply chain because a supply chain stage either 18 18 16 16 produces or purchases in lots that are larger than 14 14 those demanded by the customer 12 12 � Q = lot or batch size of an order 10 10 8 8 � D = demand per unit time 6 6 � Cycle inventory = Q/2 (depends directly on lot size) 4 4 2 2 � Average flow time = Avg. inventory / Avg. flow rate 0 0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 16 17 18 19 20 21 � Average flow time from cycle inventory = Q/(2D) Days Days � � Role of Cycle Inventory Role of Cycle Inventory Safety Inventory Safety Inventory Ω Ω in a Supply Chain in a Supply Chain Stochastic demand: distinguishing predicted demand Q = 1000 units from the actual demand D = 100 units/day Cycle inventory = Q/2 = 1000/2 = 500 = Avg. 1200 1200 Cumulative Cumulative Inflow and Inflow and inventory level from cycle inventory outflow outflow 1000 1000 Cumulative Cumulative inflow inflow Avg. flow time = Q/2D = 1000/(2)(100) = 5 days 800 800 � Cycle inventory adds 5 days to the time a unit Safety Safety 600 600 inventory inventory spends in the supply chain 400 400 � Lower cycle inventory is better because: Cumulative Cumulative 200 200 outflow outflow � Average flow time is lower 0 0 � Lower inventory holding costs 1 1 3 3 5 5 7 7 9 9 1 1 3 3 5 5 7 7 9 9 1 1 3 3 5 5 7 7 9 9 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 2 2 Days of the month Days of the month � � Printed with FinePrint - purchase at www.fineprint.com

The Role of Safety Inventory The Role of Safety Inventory Role of Safety Inventory Role of Safety Inventory ٠٠in a Supply Chain in a Supply Chain � Average inventory is therefore cycle inventory plus � Forecasts are rarely completely accurate safety inventory � If average demand is 1000 units per week, then half the � There is a fundamental tradeoff: time actual demand will be greater than 1000, and half the � Raising the level of safety inventory provides higher levels time actual demand will be less than 1000; what happens of product availability and customer service when actual demand is greater than 1000? � Raising the level of safety inventory also raises the level of � If you kept only enough inventory in stock to satisfy average inventory and therefore increases holding costs average demand, half the time you would run out � Very important in high-tech industries where � Safety inventory: Inventory carried for the purpose of obsolescence is a significant risk (where the value of satisfying demand that exceeds the amount forecasted in inventory, such as PCs, can drop in value) a given period � �� Two Questions to Answer in Two Questions to Answer in ٠٠Overview Overview Planning Safety Inventory Planning Safety Inventory � � The role of cycle and safety inventories in a � What is the appropriate level of supply chain safety inventory to carry? � Determining the appropriate level of safety � What actions can be taken to inventory improve product availability while � Impact of supply uncertainty on safety inventory reducing safety inventory? � Impact of aggregation on safety inventory �� �� Printed with FinePrint - purchase at www.fineprint.com

Determining the Appropriate Determining the Appropriate Determining the Appropriate Determining the Appropriate Level of Demand Uncertainty Level of Demand Uncertainty Ω Ω Level of Safety Inventory Level of Safety Inventory � Appropriate level of safety inventory � Measuring demand uncertainty determined by: � Supply or demand uncertainty � Measuring product availability � Desired level of product availability � Replenishment policies � Higher levels of uncertainty require higher � Evaluating cycle service level and fill rate levels of safety inventory given a particular � Evaluating safety level given desired cycle desired level of product availability service level or fill rate � Higher levels of desired product availability � Impact of required product availability and require higher levels of safety inventory uncertainty on safety inventory given a particular level of uncertainty �� �� Measuring Demand Measuring Demand Measuring Demand Measuring Demand Ω Ω Uncertainty Uncertainty Uncertainty Uncertainty � Demand has a systematic component and a random component � Normal distribution with mean D K and std. dev. σ K � The estimate of the random component is the measure of � D K : avrg. demand during k periods = kD demand uncertainty � Random component is usually estimated by the standard � σ K : std. dev. of demand during k periods = deviation of forecast error σ D Sqrt(k) � Notation: D = Average demand per period � Coefficient of variation: σ D = standard deviation of demand per period (forecast error) cv = σ/µ = (std. dev.)/mean: size of uncertainty relative to L = lead time: time between when an order is placed and demand when it is received � Uncertainty of demand during lead time is what is important �� �� Printed with FinePrint - purchase at www.fineprint.com

Measuring Product Availability Measuring Product Availability Replenishment Policies Replenishment Policies Ω Ω � Replenishment policy: decisions regarding when � Product availability: a firm’s ability to fill a customer’s to reorder and how much to reorder order out of available inventory � Continuous review: inventory is continuously � Stockout: a customer order arrives when product is not monitored and an order of size Q is placed when available the inventory level reaches the reorder point � Product fill rate (fr): fraction of demand that is satisfied ROP from product in inventory � Periodic review: inventory is checked at regular � Order fill rate: fraction of orders that are filled from available inventory (periodic) intervals and an order is placed to raise � Cycle Service Level (CSL): fraction of replenishment the inventory to a specified threshold (the “order- cycles that end with all customer demand met up-to” level) �� �� Continuous Review Policy: Safety Continuous Review Policy: Safety Inventory and Cycle Service Level Inventory and Cycle Service Level Ω Ω CSL: Cycle Service Level CSL: Cycle Service Level D = DL L : Lead time for replenishment L � CSL = Prob (demand during lead time of D: Average demand per unit L weeks ≤ ROP ) time σ = L σ L D σ D : Standard deviation of � We need to obtain the distribution of demand per period − 1 = F ( ) × σ ss CSL D L : Mean demand during lead demand during the lead time S L time � For normal distribution: ROP = D + ss σ L : Standard deviation of L demand during lead time CSL = F(ROP, D L , σ L ) CSL : Cycle Service Level D σ CSL = F ( ROP , , ) F is the cumulative normal distribution ss :Safety inventory L L function (F(x, µ , σ )) ROP : Reorder Point Average Inventory = Q/2 + ss �� �� Printed with FinePrint - purchase at www.fineprint.com

Recommend

More recommend