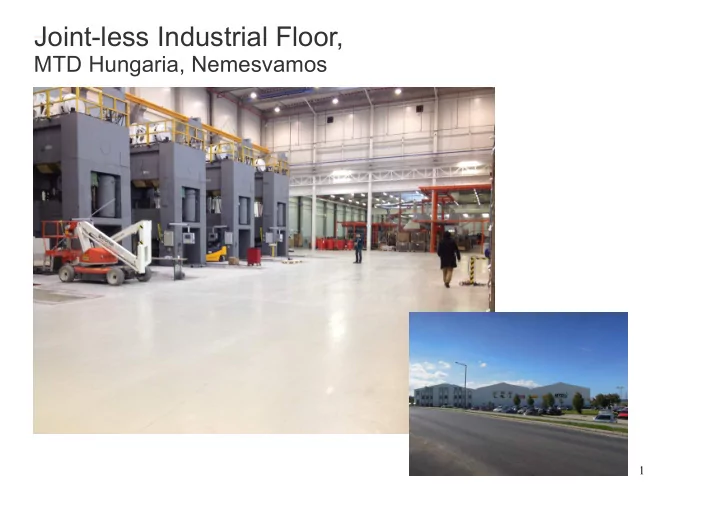

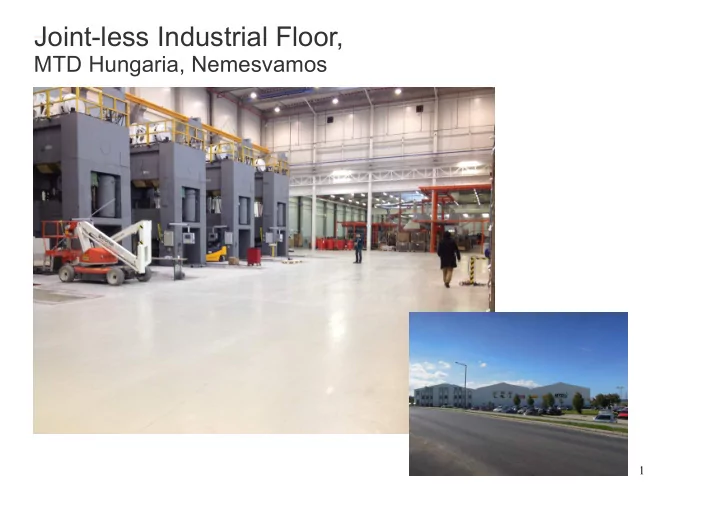

Joint-less Industrial Floor, MTD Hungaria, Nemesvamos 1

General Floor Characteristics Joint-less Industrial Floor made of Shrinkage-Compensating Concrete Joint-less : 'joint-less' doesn't mean that there are absolutely no joints in the floor. However joint-less floors have 80-90% less joints than conventional floors. Joints : joints need to be formed at certain locations, e.g.: where daily concrete pour is finished (this is called construction joint), or at critical floor locations where stress needs to be reduced. These joints are steel armored to protect joint edges from spalling and the prefabricated joint profiles inculde plate dowels for effective load transfer between the floorpanels separated by the joint. Concrete : expansive concrete made with DENKA CSA #20, C30/37-XC1-32-F3 Subgrade : 35 cm crushed rock, E 2 =100-130 N/mm 2 Floor thickness : 15 cm Load bearing capacity : 12 ton/rack leg; 15 ton/m 2 Floor flatness and levelness : FF35/FL20 2

Floor Design Structural Design Industrial floors are multi-layered structures: Sub-soil Sub-grade Concrete slab For floor design sub-soil characteristics were taken into account, sub-grade and concrete slab was designed for the applied loads. Design criterium: concrete slab remains crack-free. Locating joints correctly is vital for crack free floors. The employed flooring technology allows 40 meter joint spacing without any cracks (as opposed to 5-7 meter joint spacing, as in case of conventional flooring). Also, long and narrow floor sections can be built without cracking. 3

Floor Design Joint locations (indicated by black arrows below) 4

Floor Design Joint formation Joint edges subjected to small hard wheels are prone to break (spall). Any joint wider than appr. 1 mm will spall. To avoid spalling we protect joint edges with steel (See below). Effective load transfer in joints is necessary to aviod step formation between the two sides of the joint that would further deteriorate joint edges. 5

Floor Design Steel bar reinforcement Properly sized and located steel reinforcement is key to effective shrinkage compensation. If shrinkage-compensating concrete is properly and elastically restrained, it induces compressive stress in the slab that is intended to approximately offset the tendency of shrinkage to induce tensile stress. Taking into account the expansive potential of the concrete mix and the expected shrinkage, a small ratio of steel bar reinforcement was placed in the upper half of the slab. Additional reinforcement was employed around re-entrant corners to avoid cracks. 6

Floor Design Concrete mix design Shrinkage-compensating concrete expands after setting. The expansion takes place in the first 7 days. After 7 seven days -when subjected to drying- it starts shrinking. If designed properly expansion equals or it is slightly higher than the ultimate shrinkage. To confirm the above, the employed concrete mixture went under examination at the Budapest University of Technology and Economics for 28 days. Length change The following properties have been looked at: Expansion (ASTM C878) Shrinkage Fresh concrete workability Slump loss over 1,5 hours

Floor Construction Steel bar reinforcement 8

Floor Construction Steel bar reinforcement at re-entrant corners 9

Floor Construction Joint formation: steel armored joint with effective load transfer 10

Floor Construction Joint formation: steel armored joint with effective load transfer 11

Floor Construction Pouring concrete 12

Floor Construction Pouring concrete 13

Floor Construction Pouring concrete 14

Floor Construction Pouring concrete 15

Floor Construction Dosing DENKA CSA #20 expansive agent at the ready mix concrete plant 16

Floor Construction Taking concrete sample at the ready mix concrete plant Fresh concrete quality was continously checked during construction. The followings were tested: Concrete temperature Slump flow Water content Concrete density 17

Monitoring floor performance Concrete expansion and shrinkage are measured with built in strain gauges Data acquisition system Strain gauge 18

Results No cracks No joint spalling Small joint opening 19

Results Floor performance data acquired by two built in strain gauges confirms that the floor behaves as expected: 20

Results (The floor recieved epoxy coating for oil resistance) 21

Results (The floor recieved epoxy coating for oil resistance) 22

Results (The floor recieved epoxy coating for oil resistance) 23

Results Joint 24

Conclusions With no cracks and no joints to maintain the floor is practically maintenance-free. No down times No maintenance cost No headache The floor next door is a conventional floor, with closely spaced joints (6 m). It is 6 months old and the joint deterioration typical of this kind of flooring already started and joint repair will be needed soon. 25

Thank you for chosing us! 26

Recommend

More recommend