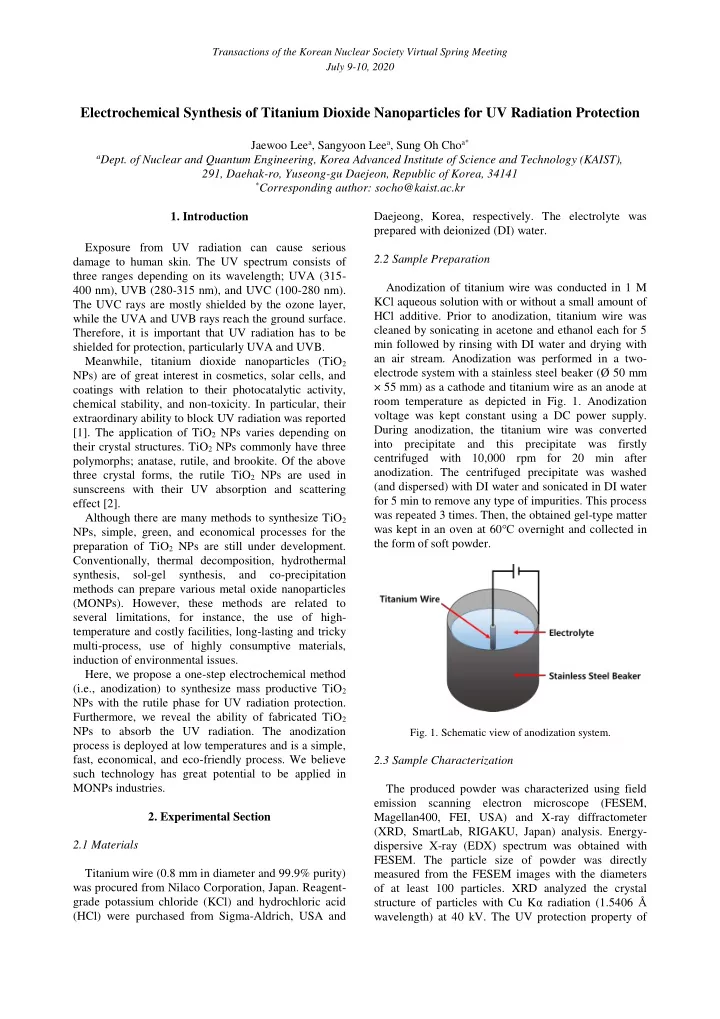

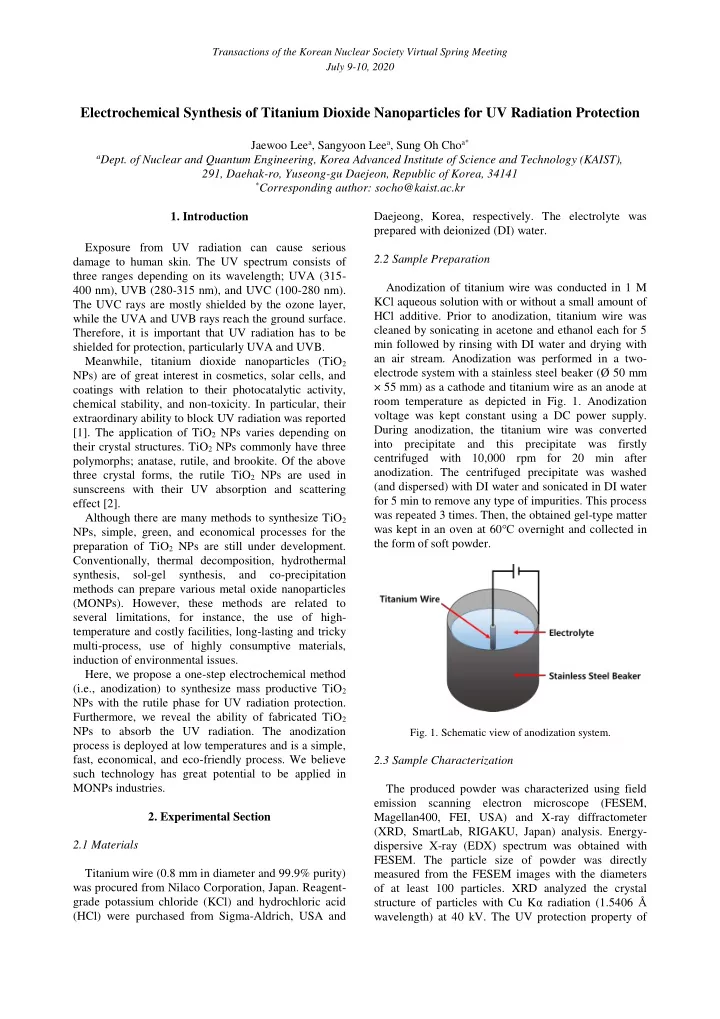

Transactions of the Korean Nuclear Society Virtual Spring Meeting July 9-10, 2020 Electrochemical Synthesis of Titanium Dioxide Nanoparticles for UV Radiation Protection Jaewoo Lee a , Sangyoon Lee a , Sung Oh Cho a* a Dept. of Nuclear and Quantum Engineering, Korea Advanced Institute of Science and Technology (KAIST), 291, Daehak-ro, Yuseong-gu Daejeon, Republic of Korea, 34141 * Corresponding author: socho@kaist.ac.kr Daejeong, Korea, respectively. The electrolyte was 1. Introduction prepared with deionized (DI) water. Exposure from UV radiation can cause serious 2.2 Sample Preparation damage to human skin. The UV spectrum consists of three ranges depending on its wavelength; UVA (315- Anodization of titanium wire was conducted in 1 M 400 nm), UVB (280-315 nm), and UVC (100-280 nm). KCl aqueous solution with or without a small amount of The UVC rays are mostly shielded by the ozone layer, HCl additive. Prior to anodization, titanium wire was while the UVA and UVB rays reach the ground surface. cleaned by sonicating in acetone and ethanol each for 5 Therefore, it is important that UV radiation has to be min followed by rinsing with DI water and drying with shielded for protection, particularly UVA and UVB. an air stream. Anodization was performed in a two- Meanwhile, titanium dioxide nanoparticles (TiO 2 electrode system with a stainless steel beaker (Ø 50 mm NPs) are of great interest in cosmetics, solar cells, and × 55 mm) as a cathode and titanium wire as an anode at coatings with relation to their photocatalytic activity, room temperature as depicted in Fig. 1. Anodization chemical stability, and non-toxicity. In particular, their voltage was kept constant using a DC power supply. extraordinary ability to block UV radiation was reported During anodization, the titanium wire was converted [1]. The application of TiO 2 NPs varies depending on into precipitate and this precipitate was firstly their crystal structures. TiO 2 NPs commonly have three centrifuged with 10,000 rpm for 20 min after polymorphs; anatase, rutile, and brookite. Of the above anodization. The centrifuged precipitate was washed three crystal forms, the rutile TiO 2 NPs are used in (and dispersed) with DI water and sonicated in DI water sunscreens with their UV absorption and scattering for 5 min to remove any type of impurities. This process effect [2]. was repeated 3 times. Then, the obtained gel-type matter Although there are many methods to synthesize TiO 2 was kept in an oven at 60 ℃ overnight and collected in NPs, simple, green, and economical processes for the the form of soft powder. preparation of TiO 2 NPs are still under development. Conventionally, thermal decomposition, hydrothermal synthesis, sol-gel synthesis, and co-precipitation methods can prepare various metal oxide nanoparticles (MONPs). However, these methods are related to several limitations, for instance, the use of high- temperature and costly facilities, long-lasting and tricky multi-process, use of highly consumptive materials, induction of environmental issues. Here, we propose a one-step electrochemical method (i.e., anodization) to synthesize mass productive TiO 2 NPs with the rutile phase for UV radiation protection. Furthermore, we reveal the ability of fabricated TiO 2 NPs to absorb the UV radiation. The anodization Fig. 1. Schematic view of anodization system. process is deployed at low temperatures and is a simple, fast, economical, and eco-friendly process. We believe 2.3 Sample Characterization such technology has great potential to be applied in MONPs industries. The produced powder was characterized using field emission scanning electron microscope (FESEM, 2. Experimental Section Magellan400, FEI, USA) and X-ray diffractometer (XRD, SmartLab, RIGAKU, Japan) analysis. Energy- 2.1 Materials dispersive X-ray (EDX) spectrum was obtained with FESEM. The particle size of powder was directly Titanium wire (0.8 mm in diameter and 99.9% purity) measured from the FESEM images with the diameters was procured from Nilaco Corporation, Japan. Reagent- of at least 100 particles. XRD analyzed the crystal structure of particles with Cu K α radiation (1.5406 Å grade potassium chloride (KCl) and hydrochloric acid (HCl) were purchased from Sigma-Aldrich, USA and wavelength) at 40 kV. The UV protection property of

Transactions of the Korean Nuclear Society Virtual Spring Meeting July 9-10, 2020 the powder was evaluated using an ultraviolet-visible spectrophotometer (UV-Vis, Lambda 1050, Perkin Elmer, USA). UV-Vis analysis was conducted by measuring the absorbance of UV rays according to wavelength. 3. Results and Discussion 3.1 Fabrication of Titanium Dioxide Nanoparticles Some white precipitate occurred when a titanium wire was anodized in 1 M KCl aqueous electrolyte at 15 V for 3 min with a stainless steel beaker as the cathode. After anodization, the edge of titanium wire became very sharp like a needle. With several times of employing centrifugation and sonication white powder was obtained (Fig. 2a). FESEM image presents particle Fig. 3. XRD pattern of TiO 2 NPs obtained via anodization in size distribution, whose average diameter is ~26.6 nm 1 M KCl aqueous electrolyte at 15 V for 3 min. (Fig. 2b). In addition, the EDX spectrum confirms that the main element components of powder are Ti and O whose atomic compositions are ~34.1% and ~65.9%, 3.2 Effects of Anodization Parameters on Crystallinity respectively. This supports the formation of TiO 2 NPs (Fig. 2c). The K and Cl peaks are due to the electrolyte The properties of oxide can be changed by and the C peak is due to carbon tape. Consquently, we controlling the anodization parameters. Such parameters verified the powder comprises TiO 2 NPs. can be temperature, time, electrolyte composition, or Further investigation for identifying the crystal voltage. First of all the duration effect on the structure of the TiO 2 NPs was performed using XRD crystallinity of nanoparticles was investigated by analysis. Fig. 3 shows that the XRD pattern of titanium changing anodization time 5, 10, and 15 min. When the oxide nanoparticles has no clear peaks over the entire 2- titanium wire is anodized for 5 min, the spectrum is theta range. Therefore, the TiO 2 NPs produced in 1 M widely broadened and there are no clear peaks (Fig. 4a). KCl solution at 15 V are amorphous. However, However, when the anodization time increase, some amorphous TiO 2 NPs are rarely used in UV radiation peaks are present and match with anatase (ICDD PDF protection so fabricating the crystalline titanium oxide No. 00-064-0863) (Fig. 4b,c). This suggests amorphous nanoparticles, particularly rutile, is an indispensable TiO 2 NPs grow in crystalline structure as anodization task in terms of UV protection. time increases. Furthermore, when anodization is in process, the temperature of electrolyte reaches up to ~90 ℃ due to local exothermic heat [3]. The local heat may help nucleation and crystallization of amorphous TiO 2 . It means amorphous TiO 2 is transformed to anatase as anodization is more in progress. Another one is the effect of the chemical composition of electrolytes due to acid additive. Fig. 5 shows the XRD spectra of each case with different amounts of HCl additive in the electrolyte. When anodizing a titanium wire for 15 min without any HCl addition, broad peaks show that anatase is produced with very low crystallinity (Fig. 5a). On the other hand, if there is a small amount of HCl in the electrolyte, the crystallinity becomes much better (Fig. 5b-d). In addition, in the cases of HCl addition, the rutile (ICDD PDF No. 01- 077-0443) phase appears as well as anatase. However, if a large amount (more than 1 M) of HCl is added to the electrolyte, no nanoparticles are produced. This may be Fig. 2. (a) Digital photograph, (b) FESEM image, and (c) due to the lack of oxygen species because the HCl reacts EDX spectrum of TiO 2 NPs obtained via anodization in 1 M with them. Respect to the effect of HCl additive, one KCl aqueous electrolyte at 15 V for 3min. plausible explanation is that neutralization and solubility affect crystallization. As HCl reacts with OH - , the heat of neutralization is generated and becomes the energy

Recommend

More recommend