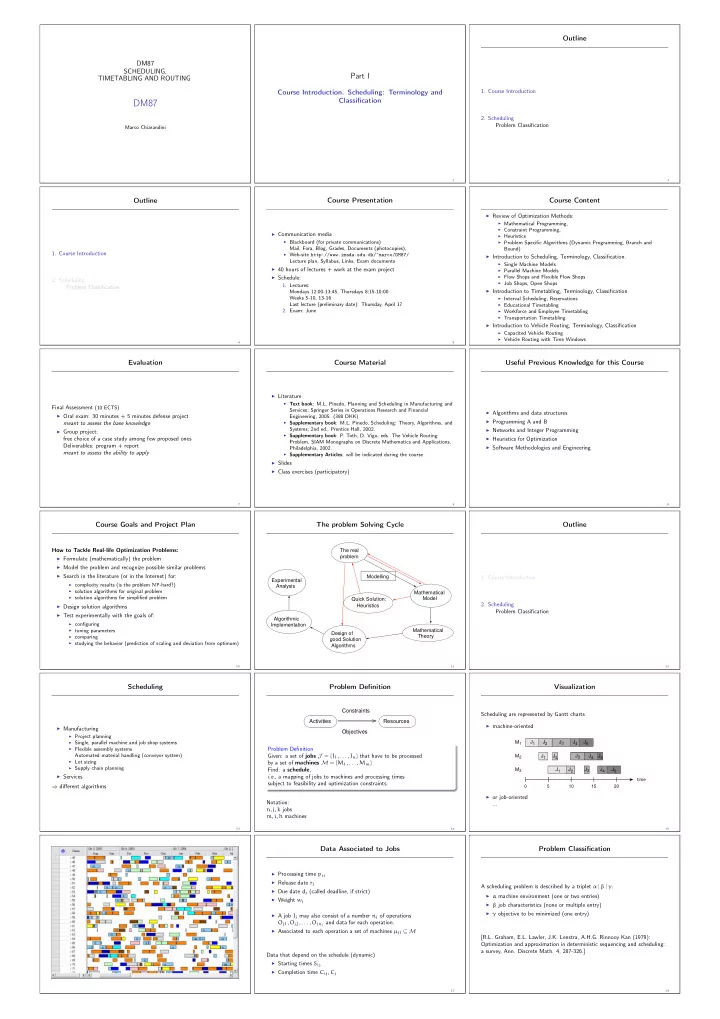

Outline DM87 SCHEDULING, Part I TIMETABLING AND ROUTING Course Introduction. Scheduling: Terminology and 1. Course Introduction Classification DM87 2. Scheduling Problem Classification Marco Chiarandini 2 3 Outline Course Presentation Course Content ◮ Review of Optimization Methods: ◮ Mathematical Programming, ◮ Constraint Programming, ◮ Communication media ◮ Heuristics ◮ Blackboard (for private communications) ◮ Problem Specific Algorithms (Dynamic Programming, Branch and Mail, Fora, Blog, Grades, Documents (photocopies), Bound) 1. Course Introduction ◮ Web-site http://www.imada.sdu.dk/~marco/DM87/ ◮ Introduction to Scheduling, Terminology, Classification. Lecture plan, Syllabus, Links, Exam documents ◮ Single Machine Models ◮ 40 hours of lectures + work at the exam project ◮ Parallel Machine Models ◮ Schedule: ◮ Flow Shops and Flexible Flow Shops 2. Scheduling ◮ Job Shops, Open Shops 1. Lectures: Problem Classification ◮ Introduction to Timetabling, Terminology, Classification Mondays 12:00-13:45, Thursdays 8:15-10:00 Weeks 5-10, 13-16 ◮ Interval Scheduling, Reservations Last lecture (preliminary date): Thursday, April 17 ◮ Educational Timetabling 2. Exam: June ◮ Workforce and Employee Timetabling ◮ Transportation Timetabling ◮ Introduction to Vehicle Routing, Terminology, Classification ◮ Capacited Vehicle Routing ◮ Vehicle Routing with Time Windows 4 5 Evaluation Course Material Useful Previous Knowledge for this Course ◮ Literature ◮ Text book : M.L. Pinedo, Planning and Scheduling in Manufacturing and Final Assessment (10 ECTS) Services; Springer Series in Operations Research and Financial ◮ Algorithms and data structures ◮ Oral exam: 30 minutes + 5 minutes defense project Engineering, 2005. (388 DKK) ◮ Programming A and B ◮ Supplementary book : M.L. Pinedo, Scheduling: Theory, Algorithms, and meant to assess the base knowledge Systems; 2nd ed., Prentice Hall, 2002. ◮ Networks and Integer Programming ◮ Group project: ◮ Supplementary book : P. Toth, D. Vigo, eds. The Vehicle Routing free choice of a case study among few proposed ones ◮ Heuristics for Optimization Problem, SIAM Monographs on Discrete Mathematics and Applications, Deliverables: program + report ◮ Software Methodologies and Engineering Philadelphia, 2002. meant to assess the ability to apply ◮ Supplementary Articles : will be indicated during the course ◮ Slides ◮ Class exercises (participatory) 7 8 9 Course Goals and Project Plan The problem Solving Cycle Outline How to Tackle Real-life Optimization Problems: The real problem ◮ Formulate (mathematically) the problem ◮ Model the problem and recognize possible similar problems ◮ Search in the literature (or in the Internet) for: Modelling 1. Course Introduction Experimental ◮ complexity results (is the problem NP -hard?) Analysis ◮ solution algorithms for original problem Mathematical ◮ solution algorithms for simplified problem Model Quick Solution: 2. Scheduling ◮ Design solution algorithms Heuristics Problem Classification ◮ Test experimentally with the goals of: Algorithmic ◮ configuring Implementation ◮ tuning parameters Mathematical Design of ◮ comparing Theory good Solution ◮ studying the behavior (prediction of scaling and deviation from optimum) Algorithms 10 11 12 Scheduling Problem Definition Visualization Constraints Scheduling are represented by Gantt charts Activities Resources ◮ machine-oriented ◮ Manufacturing Objectives ◮ Project planning ◮ Single, parallel machine and job shop systems M 1 J 1 J 2 J 3 J 4 J 5 ◮ Flexible assembly systems Problem Definition Automated material handling (conveyor system) Given: a set of jobs J = { J 1 , . . . , J n } that have to be processed M 2 J 1 J 2 J 3 J 4 J 5 ◮ Lot sizing by a set of machines M = { M 1 , . . . , M m } ◮ Supply chain planning Find: a schedule , M 3 J 1 J 2 J 3 J 4 J 5 ◮ Services i.e. , a mapping of jobs to machines and processing times time subject to feasibility and optimization constraints. ⇒ different algorithms 0 5 10 15 20 ◮ or job-oriented Notation: ... n, j, k jobs m, i, h machines 13 14 15 Data Associated to Jobs Problem Classification ◮ Processing time p ij ◮ Release date r j A scheduling problem is described by a triplet α | β | γ . ◮ Due date d j (called deadline, if strict) ◮ α machine environment (one or two entries) ◮ Weight w j ◮ β job characteristics (none or multiple entry) ◮ γ objective to be minimized (one entry) ◮ A job J j may also consist of a number n j of operations O j1 , O j2 , . . . , O jn j and data for each operation. ◮ Associated to each operation a set of machines µ jl ⊆ M [R.L. Graham, E.L. Lawler, J.K. Lenstra, A.H.G. Rinnooy Kan (1979): Optimization and approximation in deterministic sequencing and scheduling: a survey, Ann. Discrete Math. 4, 287-326.] Data that depend on the schedule (dynamic) ◮ Starting times S ij ◮ Completion time C ij , C j 17 18

Recommend

More recommend