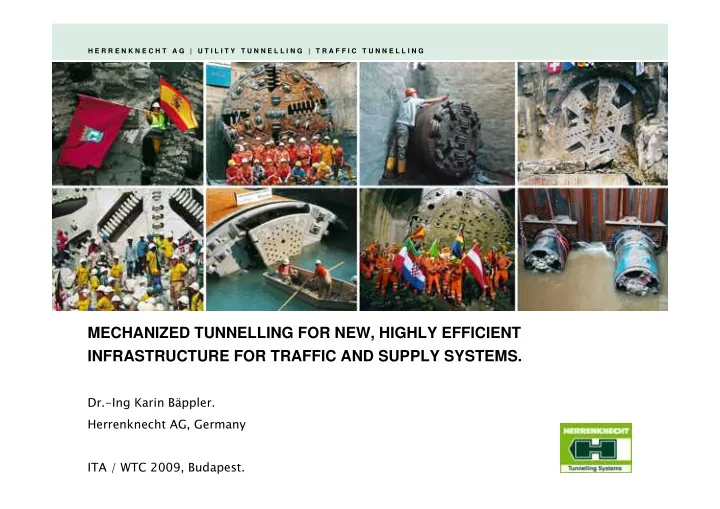

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G MECHANIZED TUNNELLING FOR NEW, HIGHLY EFFICIENT INFRASTRUCTURE FOR TRAFFIC AND SUPPLY SYSTEMS. Dr.-Ing Karin Bäppler. Herrenknecht AG, Germany ITA / WTC 2009, Budapest.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G MECHANIZED TUNNELLING FOR NEW, HIGHLY EFFICIENT INFRASTRUCTURE FOR TRAFFIC AN SUPPLY SYSTEMS. � Demand for underground infrastructure � Newest techniques in mechanized tunnelling � Hydroshields � Convertible Shields � EPB Shields � Hard Rock TBMs � Summary

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G THE DEMAND FOR UNDERGROUND INFRASTRUCTURES. � Population growth and urbanization � New high-capacity infrastructures to keep people, goods and resources on the move � Longer and deep grounded tunnels in all kinds of geologies for every traffic and utility tunnel � Huge diameter multi-purpose tunnels � Large scale infrastructure schemes with many simultaneous sub-projects � Tunnels for megacities � High-speed trains, hydropower, irrigation, sewage

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G JOBSITE MICROTUNNELLING.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G PIPE ARCH PROJECT IN BERLIN.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G PIPE ARCH PROJECT IN BERLIN. Pipe Arch Project | Metro Station Brandenburger Tor | Berlin | Germany M-988M Geology: Sand (with inclusions of gravel, 2 X AVN1200TC stones and blocks), groundwater Length of drives: 90m Diameter (extended): 1,610mm Number of drives: 30 Customer: WüWa-Bau GmbH

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G 1 Excavation tool 3 Steering cylinder 5 Air lock AVN MACHINE. 2 Crusher 4 Drive unit 6 Slurry line 7 Feed line 5 Access hatch AVND MACHINE. 1 Excavation tool 3 Compressed air cushion 6 Air lock 2 Crusher 4 Bentonite filling 7 Pressure regulator

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G River Neva Crossing | St. Petersburg | Russia AVND2000 Outer diameter: 2,540mm Tunnel length: 775m Geology: loam, fine sand, cobbles, clay Contractor: Lenims

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G HORIZONTAL DIRECTIONAL DRILLING.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G Bei Qing Huzhou Gas Pipeline | China HK250T Pipeline Diameter: 813mm Pulling Force: 2,500kN

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G Mixshield MODE MODE Slurry Compressed Air EPB Hard Rock

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G SOFT GROUND MACHINES. EPB / MIXSHIELD RANGE. Sieve Size Gravel Silt Sand Clay Fine Medium Coarse Fine Medium Coarse Fine Medium Coarse Portion of grains < d in % of the total amount 100 90 80 70 60 50 40 30 20 10 0 0,001 0,002 0,006 0,02 0,06 0,2 0,6 2,0 6,0 20.0 60,0 S i e v e r e s i d u e i n w e i g h t % Grain diameter d (mm) EPB Methods Mixshield Methods

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G MIXSHIELD. SAFE TUNNELLING IN VARYING GROUND.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G PERFORMED PRESSURE DURING TUNNELLING. 15,0 HALLANDSAS - MIXSHIELD ø 10.5m WESTERSCHELDE Gneiss - MIXSHIELD ø 11.4m - 13.0 SAND; CLAY 12,5 WESERTUNNEL MÜLHEIM - MIXSHIELD ø 11.4m - - MIXSHIELD ø 6.9m - GRAVEL; CLAY; SANDSTONE; CLAYSTONE BOULDERS 10,0 HAMBURG GRAUHOLZ SHANGHAI - MIXSHIELD ø 14.2m - - MIXSHIELD ø 11.6m - - MIXSHIELD ø 15.4m GRAVEL; CLAY; BOULDERS 7.5 SAND; GRAVEL; MOLASSE SAND, GRAVEL [bar] 7,5 6.5 HERA HAMBURG SYDNEY - MIXSHIELD ø 6.0m - - MIXSHIELD ø 10.4m - 5.5 SAND; GRAVEL SANDSTONE; CLAY 5,0 4.0 3.5 3.5 2.5 2,5 0,0 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 9 0 1 2 3 4 5 6 7 8 8 8 8 8 8 8 8 8 8 9 9 9 9 9 9 9 9 9 9 0 0 0 0 0 0 0 0 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 9 0 0 0 0 0 0 0 0 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 1 2 2 2 2 2 2 2 2 DIVERS ENGAGED

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G MIXSHIELD. GENERAL LAYOUT. 1 Submerged wall 2 Working chamber 3 3 Air cushion 1 4 Pressure bulkhead 2 4

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G ACCURATE PRESSURE CONTROL VIA AIR CUSHION. 3 2 Reference pressure pressure (bar) 1 Support pressure control via air cushion 0 0 10 20 30 40 50 time (sec)

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G THE WORLD’S LARGEST TBMs. S-317 and S-318 | Changjiang Under River Tunnel | Shanghai | China 2 Mixshields Shield diameter: 15,430mm Cutterhead power: 3,500kW Tunnel length: 7,170m each Geology: Sand, clay, shell debris End user: Shanghai Changjiang Tunnel & Bridge Construction Co., Ltd.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G ACCESSIBLE CUTTING WHEEL SPOKES FOR TOOL CHANGE IN FREE AIR.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G MAJOR TECHNICAL INNOVATIONS AT PROJECT 4 th TUBE ELBE TUNNEL. CUTTING TOOL CHANGE IN FREE AIR. � Access to the main arm of the cutting wheel under atmospheric pressure � Operator undertakes maintenance procedures without the risk of having to work at the tunnel face � Back loading cutting tools

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G EFFICIENT SOFT GROUND TUNNELLING WITH ELECTRONIC WEAR DETECTION SYSTEM. � Actual information about cutting tool wear � Economical tool change � Limited damage on steel structure

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G A CHALLENGING TIME SCHEDULE. � Date of contract: February 8, 2005 � Start tunnelling S-317: September 2006 S-318: December 2006 � Breakthrough S-317: May 2008 S-318: September 2008 � In total 75,000 lining segments (16 t each) for 14,340m of tunnel. � Tunnel will be opened for the traffic in time for the World Expo 2010.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G SHANGHAI, CHINA. BREAKTHROUGH OF THE WORLD‘S LARGEST TUNNEL BORING MACHINES. � S-317 � S-318 May 28, 2008 September 5, 2008

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G THE WESTERSCHELDE ROAD TUNNEL PROJECT, THE NETHERLANDS.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G GEOLOGY AT WESTERSCHELDE. PRESSURE OF UP TO 7.5 BAR.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G MACHINE FEATURES AGAINST CLOGGING BEHAVIOR.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G WORKING IN UP TO 7.5 BAR. � Pressure chamber system for up to 12 divers and technicians enables divers a long-term stay under pressure � Transport shuttle: � Length: 2,500mm � Diameter: 1,300mm � Diver Capacity: 4

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G BREAKTHROUGH AFTER 6.6 KILOMETERS.

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G HALLANDSAS TUNNEL – PUSHING THE LIMITS OF MECHANIZED TUNNELLING. � Key element for high speed rail link Gothenburg - Malmö � Project history since 1992 � First attempts 1993 - 1997 � Feasibility studies 1998-2000 � Rebid 2001-2002 won by Skanska/Vinci JV

H E R R E N K N E C H T A G | U T I L I T Y T U N N E L L I N G | T R A F F I C T U N N E L L I N G S-246 | Hallandsas | Sweden Convertible Mixshield (Hard Rock – Slurry) Diameter: 10,530mm Tunnel length: 2 x 5,500m Cutterhead power: 4,000kW Geology: Gneiss, Amphibolite, Diabase Dykes Customer: Skanska/Vinci JV

Recommend

More recommend