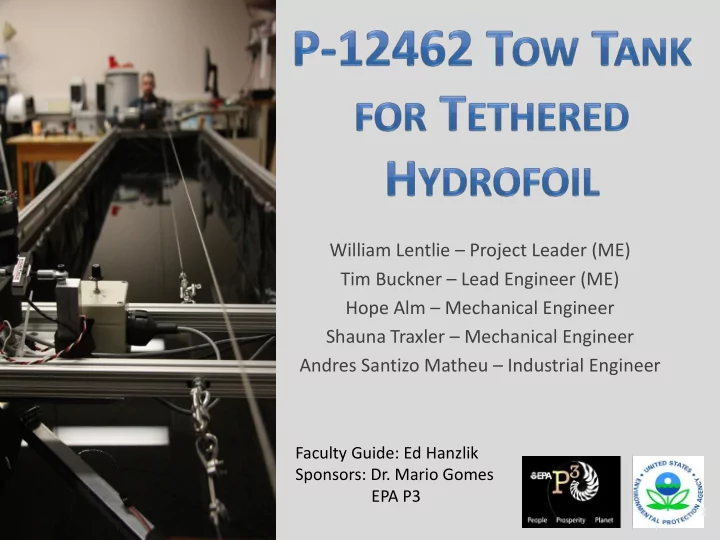

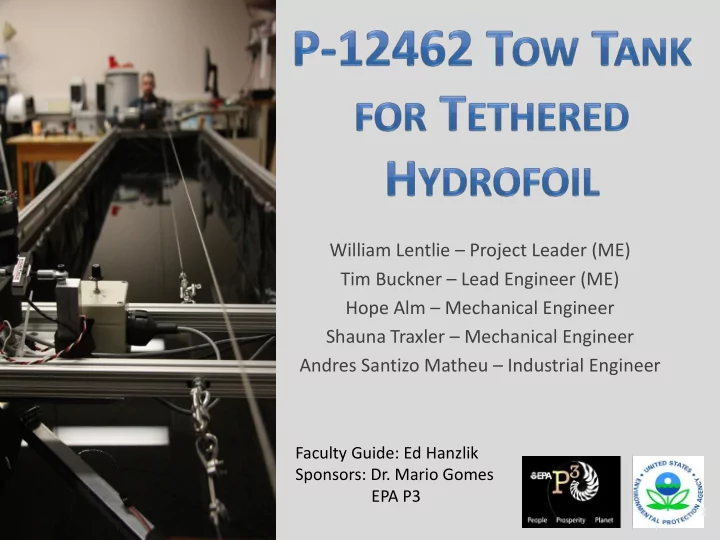

William Lentlie – Project Leader (ME) Tim Buckner – Lead Engineer (ME) Hope Alm – Mechanical Engineer Shauna Traxler – Mechanical Engineer Andres Santizo Matheu – Industrial Engineer Faculty Guide: Ed Hanzlik Sponsors: Dr. Mario Gomes EPA P3

• Project overview • System design • Actual design summary • Testing • Conclusions • Recommendations • Questions http://www.cityofsouthlake.com/waterconservation

• To build a small scaled version of tethered hydrofoil to compare with a simulation provided by Dr. Mario Gomes in MATLAB. • Create a tow tank capable of moving a platform at a constant specified speed over the top of a stationary body of water in order to recreate a river flow passing over a hydrofoil. http://emsolo.wordpress.com/category/college-life/

Importance Description How its being Accomplished Tank size meets specification Tow tank must be able to tow a platform above Motor Speed controlled with driver 9 the surface of a stationary body of water at a Driver has different speed ranges constant speed Calculated from F=ma+Fdrag Tank size meets specification The platform must allow an attachment of two Tank weight is below required by floor different instrumented systems, a set of 3 stationary hydrofoils and a model of a translating hydrofoil system Interface allows for different attachments Tank size meets specification Tank length = 16ft Tow length needs to be large enough to achieve 9 steady state Driver will control speed and accel/decel can be set for 0-30sec Tank size meets specification System size should allow for appropriately scaled 9 Total approximate weight = 150lbs model testing Calculated from F=ma+Fdrag Platform should be above or to the side of the 3 Cart has multiple attachment points water with no moving parts under water

Importance Description How its being Accomplished Platform must allow for bolting of the 9 instrumented model away from the wall of the Cart has multiple attachment points tank Encoder, DC driver speed sensor Deflection calculations performed in ANSYS Measurement device should match specification Measurements should be of high quality and DC drive accuracy ± 1/2 rpm, encoder 9 should be made with appropriate sampling rates mounted and resolution Measurement device should match specification Measurement device should match specification Timed in Labview The tank must be safe for the operator and those Ergonomics was considered in the height of 9 around them tank Membrane or sealant will be used to stop 9 The tank must not damage the surroundings leaks 3 The tank must be cost effective Cost meets budget Labview useability will be a priority 3 Easy to use and to train new users Users Manual / Video will be provided Tank should not interfere with operation of 9 P12463 is aware of the size constraints models

Specification Value <= 19ft in length and 50in in Size width Weight 300 lbf/ft^2 System Cost < $2000 Distance Cart Travels 16ft Velocity of Cart 3.28 ft/s Towing Velocity Variation 0-3.28 ft/s Towing Force 60lbs Max Sideways Deflection of Rail System 1/32" Center of Platform From Edge of Tank 1 <= 8 in Data Sampling Rates 500 Hz Resolution of Velocity Data (0.032 +/- 0.164) ft/s Resolution of Force Data (.1 +/- .2) lbf Resolution of Distance Data (3/8 +/- 1 7/8) in Resolution of Time Data (0.001 +/- 0.01 s) Setup Time (By User) < 30 min Can Test Different Models and Hydrofoil Sets > 2 sets Compliance with Accepted Safety Protocols and In Compliance with All Standards Regulations Tank is Designed so Model is Not Restricted in its Tank does not Interfere with Motion Model Tank assembly does not damage its surroundings Tank causes no Damage Training Time (1st Time) < 60 min http://engineeringmyfuture.webs.com/

Sept 11 • Planning: Customer Needs & Engineer Specs Sept 11 • Concept Development: Brainstorm, Concept Evaluation Oct 11 • System Review: Pool vs. Tank, System Architecture Nov 11 • Detail Design Review: BOM, Feasibility Analysis Jan 12 • Manufacturing: Mini-Tank, Full Scale Tank Dec 11 Feb 12 • Testing: Functionality, System Interaction Feb 12 • Final Product: Delivery, Final Presentation

Proposed concepts for the tank materials. • Wood structure and wood panels • Steel structure and wood panels • Steel structure and steel panels Proposed concepts for rails and cart • Angle iron rails and skate bearings • 80/20 linear motion system • Machined bottom supported rail

Forces applied • Hydrostatic Force at maximum height • Point load of 200 lbf (889.64 N) Constraints • Deflection: 1/32” (7.94e-4 m) • Yield Stress: 50 ksi (345 Mpa) Dimensions [in] FOS Stress FOS Deflection Angle Iron 2x2x.125 (Length) 6.42 2.25 Length with -100lbf point load 0.67 0.28 Length with +100lbf point load 0.83 0.37 Angle Iron 2x2x.375 with 2x2x.25 20.45 9.64 Length with -100lbf point load 4.39 1.93 Length with +100lbf point load 6.34 3.09 Length with -200lbf point load 2.38 1.06 Length with +200lbf point load 2.85 1.34

• 3/8 in (9.525 mm) thick, 2” SQ. (5.080 cm) Angle iron • 1/4 in (6.350 mm) thick, 2” SQ. (5.080 cm) Angle iron • 3/4 in (19.050 mm) thick Plywood • 16 feet (4.877 m) long 80/20 Aluminum • 3/4 hp (559.270 w) Motor • 1/16 in (1.588 mm) diameter Aircraft Cable • 6 in (15.240 cm) diameter Pulleys

• Tanks dimensions: 16 feet (4.877 m) long, 2.5 feet (0.762 m) wide, and 2 feet (0.610 m) high. • Max cart towing velocity: 3.21 ± 0.10 ft/s (0.950 ± 0.025 m/s) • Max volume of water: 599 US gallons (2,265 L) • 2 modular pieces, capable of being disassembled, moved, and reassembled by 2 people

• Velocity Range • Distance Accuracy • Start Up Transients • Cable Wear

Initial Budget: $2,000 Expanded Budget: $2,500 Final Expenses: $2,169.05 Tank QTY COST Tank Walls 23/32" Plywood - 4' x 8' Sheets 4 $87.48 Tank Walls 23/32" Plywood - 4' x 8' Sheets - Mini-Tank Design 1 $21.87 Tank Walls #10 x 1in. Flat Head Phillips Drive Wood Screw (100 pcs) 1 $21.87 Tank Support 2" x 2" x 1/4" Steel Angle - 22-7/8" LG. - Mini Tank & Large Tank 4 $87.48 Tank Support 2" x 2" x 1/4" Steel Angle - 25-3/4" LG. 2 $43.74 Motor DC Motor Motion Transfer from Motor 1 $0.00 DC Drive Speed control and Power Supply 1 $0.00 Speed Sensor Feedback loop to DC driver 1 $0.00 Motion System 1/16" Cable Wire Rope - Aircraft Cable 1/16", 7x7, by the foot 100 $13.00 Drive Pulley Transfers Motion 1 $9.16 Pulley Pulley with plain bronze bearings 1 $10.50 Rail and Platform Length Rails 1" x 1" T-Slotted Extrusion 2 $64.88 Width Rails and Supports 1" x 1" T-Slotted Extrusion-97" 1 $29.08 http://shannonpenrod.wordpress.com/2010/06/29/money-makes-the-world-go-around/

• Waterproofing plywood • Liner management • Leak detection • Tow cable management • Safety

Customer Needs Importance Description How its being Accomplished Comments and Objectives Tow tank must be able to tow a Tank size meets specification platform above the surface of a Motor Speed controlled with driver CN1 9 stationary body of water at a Driver has different speed ranges constant speed Calculated from F=ma+Fdrag Need was removed by customer The platform must allow an Tank size meets specification CN2 3 attachment of two different Tank weight is below required by floor instrumented systems, a set of Interface allows for different attachments Tank size meets specification Cart cannot travel full 16 ft, because of Tow length needs to be large Tank length = 16ft CN3 9 boom arm length enough to achieve steady state Driver will control speed and accel/decel can be set for 0-30sec System size should allow for Tank size meets specification CN4 9 appropriately scaled model Total approximate weight = 150lbs testing Calculated from F=ma+Fdrag Platform should be above or to CN5 3 the side of the water with no Cart has multiple attachment points moving parts under water Platform must allow for bolting of CN6 9 the instrumented model away Cart has multiple attachment points from the wall of the tank Encoder, DC driver speed sensor Labview motor control needs attention Deflection calculations performed in ANSYS Measurement device should match Measurements should be of high specification quality and should be made with CN7 9 DC drive accuracy ± 1/2 rpm, encoder appropriate sampling rates and mounted resolution Needs were removed by customer Measurement device should match specification Measurement device should match specification Timed in Labview The tank must be safe for the Ergonomics was considered in the height of CN8 9 operator and those around them tank The tank must not damage the Membrane or sealant will be used to stop Liner does not satisfy concerns on leak CN9 9 surroundings leaks prevention Went over initial budget of $2000, but CN10 3 The tank must be cost effective Cost meets budget stayed well under secondary budget of $2500 In process of creating Labview Labview useability will be a priority CN11 3 Easy to use and to train new users Directions Users Manual / Video will be provided Tank should not interfere with http://flowers.cdd5.com/showthread.php/amigo-semaforo/ CN12 9 P12463 is aware of the size constraints operation of models

Recommend

More recommend